Dynatec Systems Inc.

- Home

- Companies & Suppliers

- Dynatec Systems Inc.

- Downloads

- The Dynatec Difference HiRate™ MBR ...

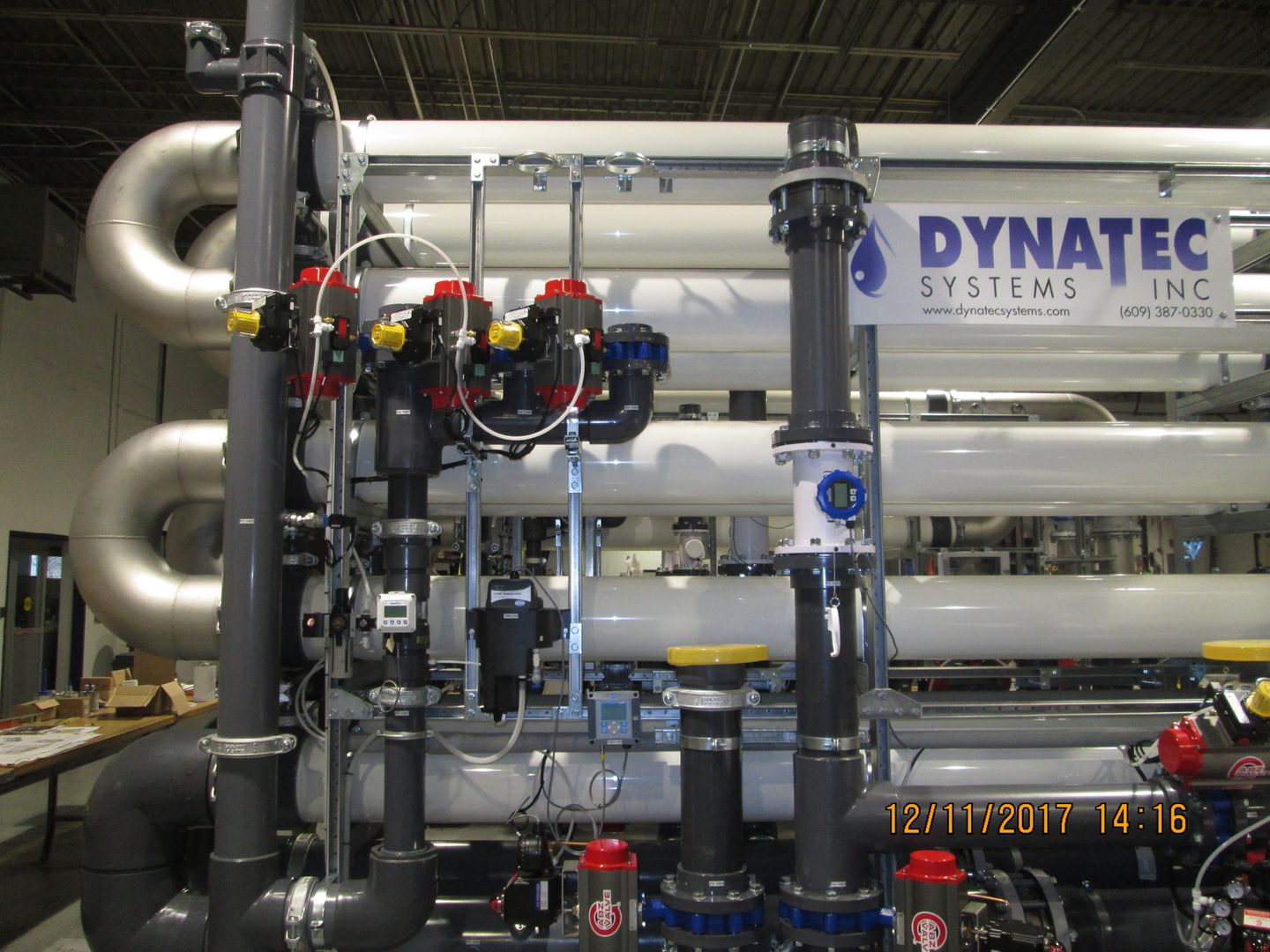

The Dynatec Difference HiRate™ MBR Dynatec Systems’ HiRate™ MBR uses external crossflow type UF membranes that have over three times the flux as t

The Dynatec Difference HiRate™ MBR

Dynatec Systems’ HiRate™ MBR uses external crossflow type UF membranes that have over

three times the flux as the hollow fiber and flat sheet alternatives (60-90 GFD vs.15-20

GFD for hollow fibers and flat sheet). Higher flux means less membrane surface area,

ultimately saving capital cost. Bio-reactor aeration alternatives include coarse bubble

aeration for commercial systems or, for higher strength industrial waste, the use of more

efficient jet aeration for improved performance and power savings.

“True UF” Filtration using 0.03 micron, cross flow, tubular membranes. Others use

microfiltration (MF) with pore sizes 0.1- 0.4 micron, allowing more contaminants to make

their way across the membrane surface. Dynatec Systems has installed over 600 membrane

systems providing wastewater solutions since 1997. The HiRate™ MBR combines sound

engineering and effective process design with state of the art materials of construction.

Outsource your wastewater service! Dynatec will design-build-own-operate-maintain your

wastewater treatment plant allowing you to concentrate on your core business.

Graphic shows flow of bio-mass and treated water through membrane

Industrial

High effluent quality

Low space requirements

High nitrogen removal

efficiency

High strength waste

Low space requirements

Thermophillic treatment

Retrofits

Increase capacity without

adding tank volume

Add external membranes to

existing treatment for higher

quality effluent

High nitrogen removal

efficiency

Solves settling problems

Commercial

Recycle//Reclamation

Low space requirements

High nitrogen removal

efficiency

Leach field//soil limitations

Decentralized applications

Variety of UF membrane Sizes

8 mm & 14 mm tubular

products are selected

depending on the application.

HiRate™ MBR - Advantages Over Other Treatment:

It is a simple controllable operation and requires less operator attention.

Reliable high quality effluent.

Smaller footprint - high MLSS levels (8,000 - 25,000 mg//l and higher).

High rejection efficiency of organic constituents, solids and microorganisms.

Lower effluent turbidity.

Excellent nutrient removal capability (<3 mg//l total N).

Lower sludge yield (0.25 - 0.35 #MLSS//# BOD5).

Operates at higher sludge concentrations (Less waste sludge to haul at high mixed liquor

concentrate).

Eliminates filamentous bacteria and sludge bulking problems.

Handles variable loading with higher MLSS level.

Lower chemical requirements.

Controlled environment around the membrane system.

Denitrification and carbon source feed is controlled with ORP controller.

HiRate™ MBR - Advantages over Immersed Membrane Systems:

Removing immersed membranes from the process tank is difficult and inefficient.

Cleaning is easier for operator.

No working above aeration tanks with hoist that can be dangerous. Maintenance is safer.

No annual fine bubble diffuser replacement required. Maintenance is less frequent.

Less oxygen is recycled to the denitrification zone minimizing carbon addition.

No recycle pump for denitrification UF recirculation pump provides membrane scouring and recycle.

No permeate vacuum pumps, valves and air relief valves.

No backwash pump and backwash tank.

No denitrification recycle pumps.

No hoist system for membrane removal.

No soak tank for membrane cleaning.

No dedicated blower needed for membrane air scour.

Lower capital cost than immersed membrane MBR’s.

Lower membrane replacement cost.

Hollow Fiber failure bypasses solids when potting fails.

Higher temperature membranes available for thermophillic applications.

TREATED

EFFLUENT

UF MEMBRANES

RECIRCULATION

PUMP PERMEATE

RECYCLE

BIOREACTOR

BIOMASS RETURNFEED

BLOWER

Most popular related searches