Dynatec Systems Inc.

- Home

- Companies & Suppliers

- Dynatec Systems Inc.

- Downloads

- The Dynatec Difference Membrane ...

The Dynatec Difference Membrane Configuration Ultrafiltration membrane systems in a tubular configuration Different membrane configurations ca

The Dynatec Difference

Membrane Configuration

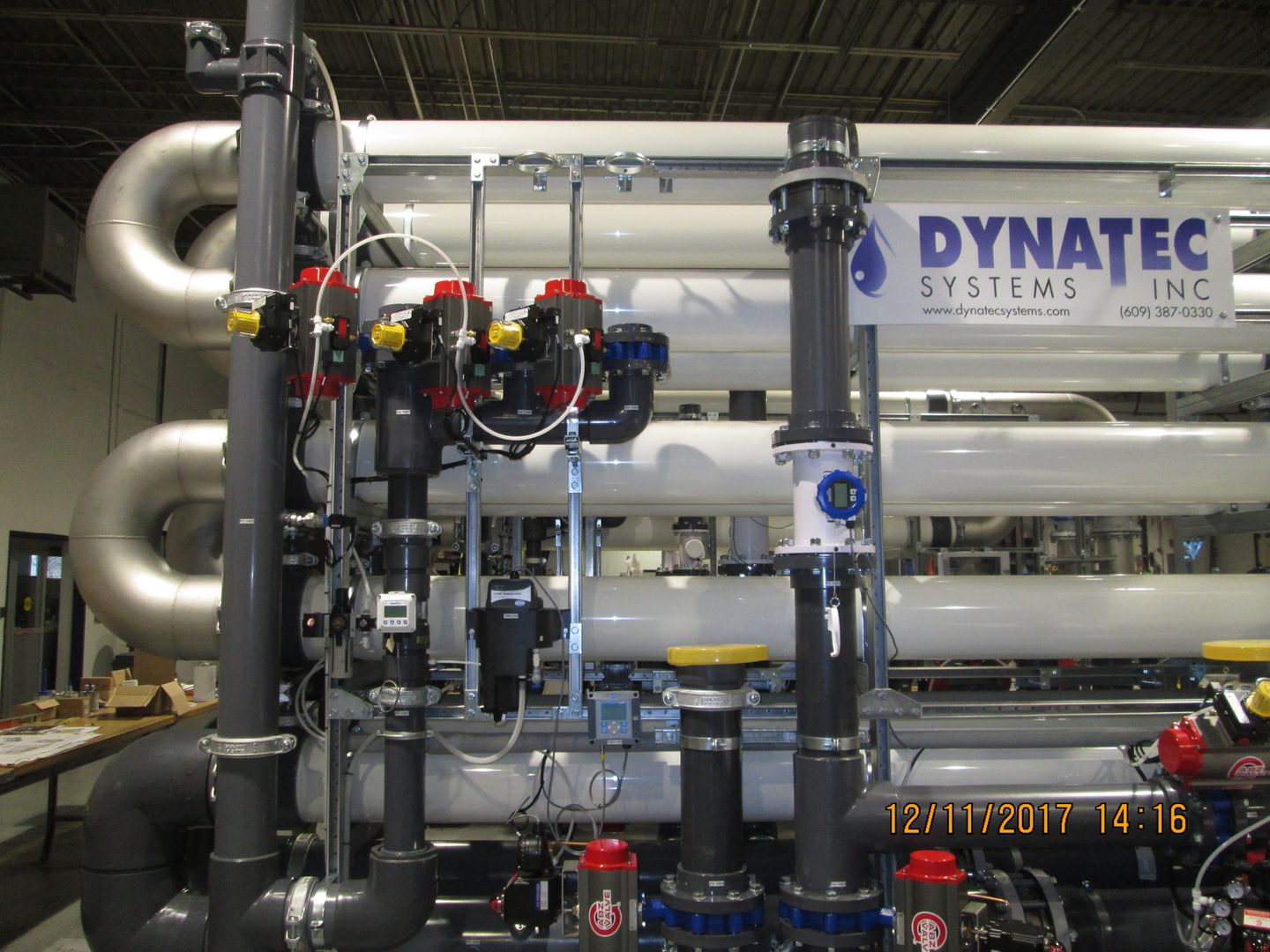

Ultrafiltration membrane systems in a tubular configuration

Different membrane configurations can be used for ultrafiltration process. Commercially

available designs in ultrafiltration modules vary according to the hydrodynamic and economic

constraints, as well as, the mechanical stability of the system under particular operating

pressures.

Tubular Membrane

The tubular module design uses polymeric membranes cast on the inside of plastic or other

components with diameters typically in the range of 5 – 25 mm with lengths from 5 – 20 ft.

Multiple tubes configurations are housed in a PVC, FRP or stainless steel shell. The feed of the

module is passed through the tubes, producing radial transfer of permeate to the shell side. This

design allows for easy cleaning.

Tubular modules are used in cross-flow, where the feed stream is passed over the surface of the

membrane. Permeate passes through the membrane while the components of the feed stream

that cannot pass through the membrane is retained and passes through and out of the system.

Low energy and high rate cross-flow operation are employed using tubular membranes,

depending on the feed fluid.

Conventional Cross-flow Operation (HiRate™)

The feed fluid passes across the membrane surface at high flow rate in order to minimize the

boundary layer of the foulants on the membrane surface. This operation is used in more difficult

treatment streams, such as oily waste, and where organic and scale-forming contaminants are

present

Low cross-flow operation (HyBrid™& DynaLift™)

The feed fluid passes across the membrane surface at lower flow rate. The DynaLift™ uses air to

help create energy at the membrane wall to minimize the fouling layer. Periodically, the

membrane is backwashed to prevent foulants from accumulating on the membrane surface.

Higher Quality

Rugged construction

Pressure, temperature and flow

using transmitters

Easy to navigate HMI screens

CPVC pipe to allow warm

cleanings

Better Performance

Positive circulation rate

produces higher and more

stable flux

High concentration due to low

reject with large tubular

modules

100% removal of suspended

and colloidal contaminants

Greater Dependability and

Reliability

High performance stainless

steel dynamic seal pump

High quality transmitters

High stable flux

External membrane skids

Lower Operating Cost

Less cleaning time and chemical

Less concentrate haul away

Extremely long membrane life

Most popular related searches