Dynatec Systems Inc.

- Home

- Companies & Suppliers

- Dynatec Systems Inc.

- Downloads

- The Dynatec Difference OILY ...

The Dynatec Difference OILY WASTEWATER— TITANIUM PLANT DBOOM SYSTEM Background This company recovers titanium metal for reuse. Among other p

The Dynatec Difference

OILY WASTEWATER— TITANIUM PLANT

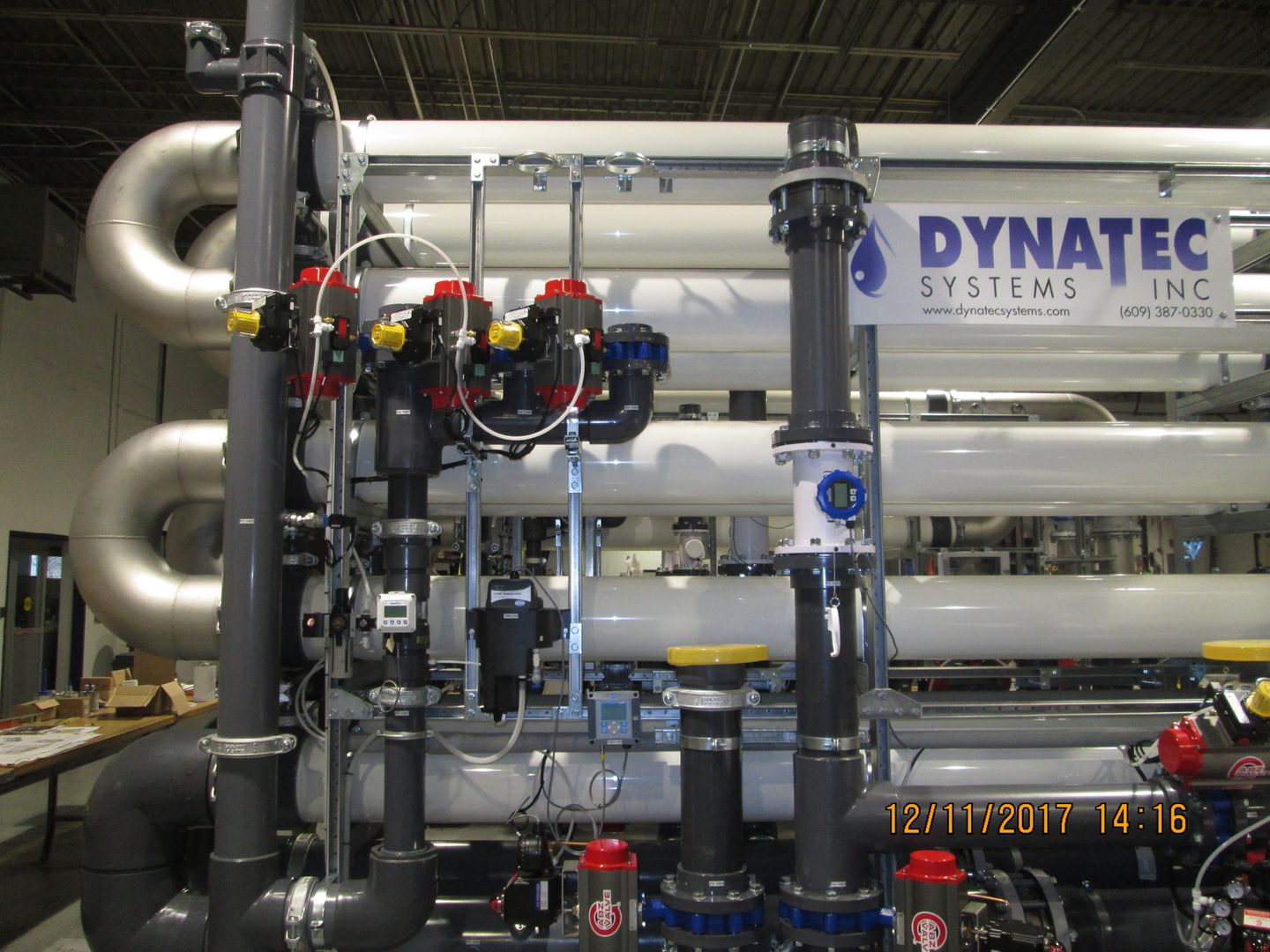

DBOOM SYSTEM

Background

This company recovers titanium metal for reuse. Among other processes, the materials are

de-oiled and washed in alkaline based chelated cleaners. This produces oily wastewater that

also contains very high levels of COD and heavy metals in solution. Some of the metals are

also complexed.

The Sale

In 1989, the titanium facility purchased an oily-waste ultrafiltration system to remove

emulsified oils and metals prior to discharge to sewer. This system worked well for many

years.

In 2003, Dynatec was approached with two requests: first, the local sewer authority had

issued a requirement to reduce COD and second, the original UF system was no longer

keeping up with the increased flows from manufacturing operations.

The final requirement was to provide a system at the lowest possible cost in a confined space

in the plant to meet demanding metals and COD requirements.

System Design

To remove COD, the selected technology was MBR. This allows for the best possible COD

reduction in the smallest possible tank space. The MBR concept that was adopted (Dynatec

HiRate™) also allowed for long sludge age, and the mixed liquor concentrations can be

operated at high levels.

Since the original UF system was no longer large enough for increased flows, a new larger UF

system was provided to remove oil, suspended solids and heavy metals. To complement this

system a new coalescing oil//water separator was provided and an enhanced metal

precipitation system. This constituted the new primary treatment system.

Since cost was an issue, Dynatec

offered to own and operate the

system under a long term

contract. This was accepted by

the company, and since startup

in 2007, the system has

performed well. The system is

operated by a part-time

operator, who visits the site

daily. In addition, Dynatec can

view and operate remotely.

Significant Savings

Minimized chemical

precipitation costs

Lowest capital cost

Low operator attention

Minimal sludge disposal

Low maintenance

Costs are fixed during

multi-year contract

Technology Benefits

Membrane separation does

not allow system upsets

Consistently high quality water

production

Ability to reuse purified water

Low operating costs

Low operator attention

required

Dynatec Services Provided

Process design

System design

Controls design

System build

System installation

Startup, commissioning and

operator training

Most popular related searches