Dynatec Systems Inc.

- Home

- Companies & Suppliers

- Dynatec Systems Inc.

- Downloads

- The Dynatec Difference Treatment of ...

The Dynatec Difference Treatment of industrial oily wastewater using tubular Ultrafiltration Problem: The automotive powertrain plant orig

The Dynatec Difference

Treatment of industrial oily wastewater

using tubular Ultrafiltration

Problem:

The automotive powertrain plant originally used a spiral configured ultrafilter (UF) and when

the spiral UF required too much care and maintenance the treatment scheme was changed to

chemical physical (C//P). The C//P system was not able to consistently remove oil.

Solution:

Dynatec’s tubular ultrafilter was selected to replace the chemical treatment system. A simple

mechanical process that includes free oil separation, Equalization, process feed and

Ultrafiltration.

There are no chemicals used other than those used to adjust pH and//or precipitate

metals

The levels of waste material for disposal are much lower than conventional

physical//chemical waste processes

The system mechanically separates and concentrates the contaminants in the

wastewater, which are then disposed

Oil & grease and TSS are essentially zero from the Dynatec Ultrafilter

Consistent high quality discharge (permeate)

Significant Savings

Waste stream concentration

lowers disposal fees

Continuous operation minimizes

labor requirement

Easy maintenance reduces labor

costs

No chemical required

Technology Benefits

Membrane Separation System

Using Tubular Ultrafilters (UF)

Simple mechanical process

Consistent high quality water

Ability to reuse purified water

Low operating costs

Unattended operation

Minimal disposal costs

Services Provided

DBOOM—Design, Build, Own,

Operate and Maintain

Systems Design

Equipment and Installation

Operator Training

Maintenance Contract

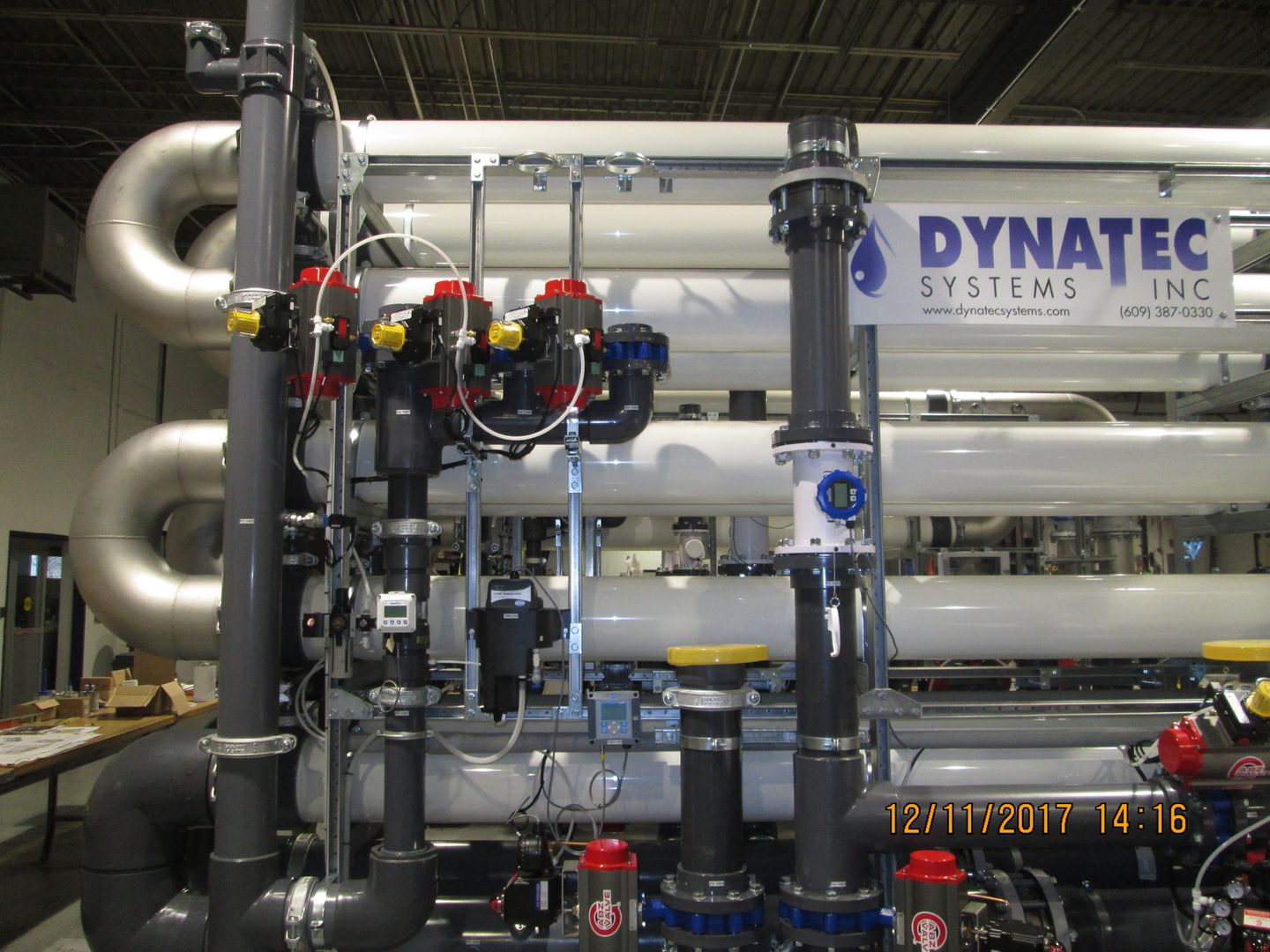

A typical membrane for oily

wastewater application

Most popular related searches