- Home

- Companies

- Henan Doing Machinery Equipment Co., ...

- News

- Tips for starting a plastic recycling ...

Tips for starting a plastic recycling plant business

As the world grapples with the impacts of plastic waste, more entrepreneurs are interested in establishing plastic recycling operations. The growing concern over environmental sustainability presents a unique opportunity for individuals to contribute positively while building a profitable business. However, many face challenges such as identifying the right technology, securing funding, and understanding regulatory requirements. This article will provide practical tips for setting up a pyrolysis plant for sale and outline the necessary steps to ensure successful operation. By addressing these points, you can create an effective plan that minimizes waste and maximizes profit.

1. Conduct Comprehensive Market Research

Why? Before any investment, understanding the market landscape is crucial for informed decision-making.

Start by analyzing the local demand for recycled plastic products and identifying potential competitors. Use surveys and analyze government reports to gauge the appetite for recycled materials in industries such as construction, automotive, and packaging.

This tip is particularly beneficial for entrepreneurs in regions with emerging markets for recycled plastics, helping them align production capacity with demand.

Key Points: Validate your business idea with data-driven insights to minimize risks.

2. Choose the Right Recycling Technology

Why? Selecting the appropriate technology can significantly impact efficiency and profitability.

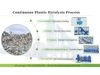

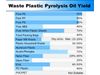

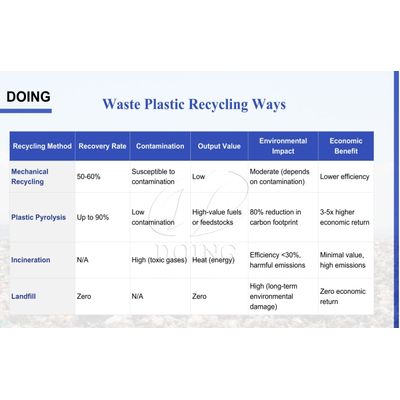

Explore various technologies such as mechanical recycling, chemical recycling, and waste plastic pyrolysis plant. Pyrolysis is particularly advantageous as it can convert plastic waste into oil, which can then be refined or used as fuel. This method has been shown to increase the conversion rate of waste plastic into reusable materials by up to 90%.

This suggestion suits those looking to handle large volumes of non-recyclable plastics, needing a solution that effectively reduces landfill dependency.

Key Points: The right technology can streamline operations and boost profitability.

3. Secure Funding and Financial Planning

Why? Sufficient capital is essential for sustaining operational phases and scaling the business.

Develop a comprehensive business plan that outlines expected costs, revenue projections, and operational expenses. Explore funding options such as government grants, loans, and private investors specifically targeting sustainable businesses. According to the “Global Recycling Market Report (2023),” the recycling industry has experienced a compound annual growth rate (CAGR) of 7.5% from 2018 to 2022, indicating robust investment potential.

This guidance is suitable for entrepreneurs seeking financial backing while presenting a sustainable business model.

Key Points: A solid financial foundation is crucial for long-term success.

4. Navigate Regulatory Requirements

Why? Compliance with local laws is essential to operate without legal impediments.

Research your country's regulations concerning waste management and recycling operations. Local environmental agencies may require permits, and adherence to workplace safety standards is critical. Engaging a legal expert familiar with waste management laws can streamline this process and help avoid fines.

This recommendation is tailored for those entering highly regulated markets or municipalities with strict recycling policies.

Key Points: Compliance ensures peace of mind and prevents costly legal issues.

5. Build Professional Relationships

Why? Networking can offer support and open doors to new opportunities.

Join local business associations focused on sustainability, connect with suppliers of raw materials, and engage with potential buyers of recycled products. Building a good rapport with stakeholders can lead to collaboration opportunities and valuable industry insights.

Ideal for those starting out and looking to establish credibility in the recycling sector.

Key Points: Effective networking can lead to partnership opportunities and enhance business visibility.

FAQ

Q: What types of plastics can be recycled with pyrolysis?

A: Pyrolysis can be used to recycle a wide range of plastics including polyethylene (PE), polypropylene (PP), and polystyrene (PS).

Q: How long does the pyrolysis process take?

A: The complete pyrolysis process can take anywhere from 4 to 24 hours depending on the quantity and type of plastic being processed.

Q: Is it profitable to start a plastic recycling plant?

A: Profitability depends on factors like operational efficiency, market demand for recycled products, and the initial investment made in technology and compliance costs. According to a report by the "International Journal of Environmental Science and Technology (2022)", companies engaging in effective plastic recycling can achieve margins exceeding 30%.

In conclusion, starting a plastic recycling plant requires careful planning, a solid understanding of market dynamics, and compliance with regulatory standards. By leveraging advanced techniques such as those offered by DOING, aspiring entrepreneurs can build a successful business that not only generates profit but also fosters environmental sustainability. Taking these steps can transform waste into wealth while contributing to a cleaner planet.