- Home

- Companies

- IMR Environmental Equipment, Inc.

- Products

- IMR - Model 5000 - 19" Continuous ...

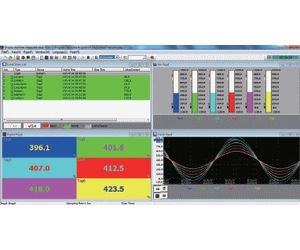

IMR - Model 5000 -19" Continuous Emissions Monitoring System

The flexibility of the IMR 5000 CEMS allows it to offer an endless set of possibilities to measure different parameters like CO, CO2, NO, NO2, CH4, HC, NH3, Cl2, HCl, H2, O3, SO2, H2S, O2, Velocity, Draft, Dust, Temperature and other parameters on request.

The IMR 5000 CEMS can calculate additional parameters like:

- CO2 (O2 Sensor required)

- Efficiency/ Losses

- Excess air / Lambda

- Reference O2

Other additional features that the IMR 5000 CEMS can offer include:

- Memory

- Observer 2 (Software)

- hourly, daily, weekly, monthly and customized reports

- Real Time Data Transfer (network)

- Remote Access

- View current readings from any internet connected device

- Automatic Email notification of alarms

- Boiler / Burners

- Turbines

- Engines

- Incinerators

- Process Control

- Landfills

- Cogeneration plants

- The IMR 5000 is state-of-the-art continuous flue-gas monitoring system, and is designed for a wide variety of flue-gas monitoring applications

- The IMR 5000 is a stand-alone analyzer that works automatically. Available in a 19” rack mount or rugged wall mounted enclosure. The wall mount enclosure meets NEMA type 4X (IP65) standards

- The modular approach of the IMR 5000 allows multiple gases (up t12 gases) tbe measured simultaneously and continuously

- The IMR 5000 uses the latest sensor technology from electro-chemical sensors tNDIR benches

- The IMR 5000 will be built tcustomer specifications

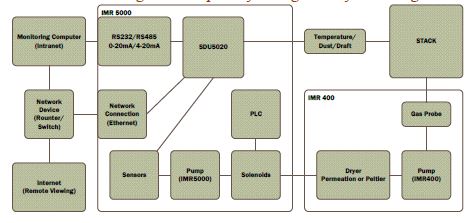

- The IMR 5000 supports the following output types: Analog 4 – 20mA, RS232 or RS485, and Ethernet (Internet)

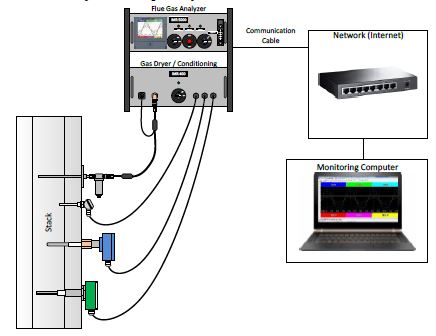

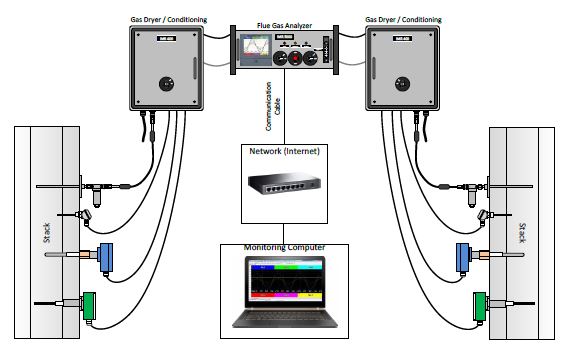

The Internal gas conditioning unit (Peltier cooler or permeation dryer) dries and conditions the gas. The conditioned flue-gas is then analyzed by the individual sensors (NDIR or Electrochemical). Processing unit inside the IMR 5000 process this information and display it on its 5.6” or 12.1” screen and relays the information ta monitoring computer provide by customer. Thanks tthe software application installed in the monitoring unit, the customer is able tmonitor this data.

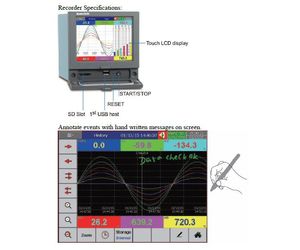

Data Logger:

- 6, 12, or 18 inputs

- 6, 12, or 18 output (4-20mA)

Communication:

- 4 – 20mA

- RS232 or RS422/485 Modbus RTU (Optional)

- Ethernet (Modbus TCP/IP)

- Webserver & Email directly from Recorder

- Storage Media (SD card 16GB)

IP or NEMA rating enclosures (Varies according tspecifications)

- Working temperature of -10 and 50oC

- Gas Temperature 0 – 1200oC

- Circuit protection

- 115VAC / 230VAC 60Hz/50Hz

- Touch Screen, TFT, 65K color

- 100 msec. scan rate

- Standard: Ethernet, SD slot & USB

- Option: RS232/422/485 & Pulse input

- Standards: CE, cULus & RoHS

- Pulse input for flow applications

- Direct Printer connectivity

- Webserver & Email directly from Recorder

- Remote Ichannels, Virtual channels

- Master/Slave, Modbus RTU and TCP protocols

- Batch operations, built in security & FDA 21 CFR part 11

- 19 international languages

Download and review recorded data; including historical trends, historical alarms and events. Search saved data by time, time period, tag, alarm, events and remarks. Data can alsbe exported inta CVS spreadsheet.

Includes all functions of Observer 1 and includes access tdata on the recorder in Real Time.