- Home

- Companies

- Janus Fire Systems

- Products

- 3M™ Novec™ - Model 1230 - Clean Agent ...

3M™ Novec™ - Model 1230 -Clean Agent Fluid Suppression Systems

3M Novec 1230 fire protection fluid is a next generation clean agent Halon alternative. It combines outstanding extinguishing performance with an excellent environmental profile. Novec 1230 fire protection fluid has zero ozone depletion potential, a global warming potential of one, a five day atmospheric lifetime, and a large margin of safety for occupied spaces. Novec 1230 fire protection fluid extinguishes fire primarily by removing heat from the fire. It is also electrically non-conductive.

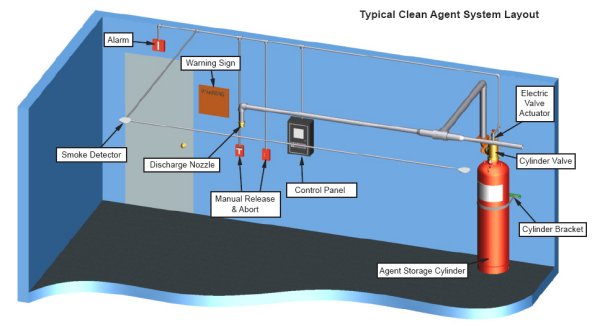

Each system consists of the following components and their associated accessories:

- Agent Storage Components – Storage components consist of the cylinder assembly(s), which contains the Novec 1230 fluid, and the cylinder bracket(s), which holds the cylinder assembly securely in place.

- Agent Fluid Distribution Components – Distribution components consist of the discharge nozzles used to introduce the Novec 1230 fluid into a protected hazard along with the associated piping system used to connect the nozzles to the cylinder assembly.

- Trim Components – Trim components complete the installation of the suppression system and consist of connection fittings, pressure gauge, low-pressure supervisory switch, electric valve actuator, and manual valve actuator.

- Slave Arrangement Components – Slave arrangement components consist of the pneumatic valve actuator(s), actuation check valve, vent check, actuation hose, and fittings required for a multiple cylinder (slave) arrangement.

- Supplemental Components – Supplemental components include the discharge pressure switch and manifold check valve. They supplement the core equipment or complete a specific multi-cylinder configuration.

- Control Panel – This device monitors the condition of the electric actuator, detectors, warning devices, cylinder pressure, and any manual release and abort stations. All electric or electronic devices must connect to the control panel in order to function.

- Detection and Alarm Devices – Detection devices coupled with manual release and abort stations maximize system efficiency while audible and visual alarm devices alert staff of alarm conditions.

Typical areas of fire protection

- Computer Rooms

- Data Storage Facilities

- Telecommunications

- Oil & Gas Petrochemical Facilities

- Museums

- Libraries and Archives

- Medical Facilities

- Manufacturing Facilities

- Storage Areas

Typical areas of fire protection

- Telecommunication facilities

- Computer rooms

- Control rooms

- Museums

- Historical archive storage

- Art galleries

- Pharmaceutical and medical facilities

- Record storage facilities

FM-200 fire extinguishing systems are designed to be discharged within 10 seconds into a room, area, or enclosure with the structural integrity to retain the agent. The FM-200 uniformly mixes throughout the protected area achieving a minimum concentration level in accordance with NFPA 2001 and/or agency listings.

Below is a list of the Janus Fire Systems Novec 1230 fluid cylinder assemblies:

- FM-200 (HFC-227ea) is formed from the elements carbon, fluorine and hydrogen (CF3CHFCF3 -heptafluoropropane). The primary extinguishing mechanism of FM-200 is heat absorption, with a secondary chemical contribution from the thermal decomposition of FM-200 in the flame.

- FM-200 leaves no residue and is safe for use in occupied spaces.

- Most common metals, such as aluminum, brass, steel, cast iron, lead, stainless steel, and copper, as well as rubber, plastic, and electronic components, are unaffected when exposed to FM-200

Although the EPA Significant New Alternative Program (SNAP) lists FM-200® as acceptable for occupied spaces, NFPA Standard 2001 and SNAP list the following guidelines for human exposure:

The discharge of FM-200 into a hazard may reduce visibility for a brief period. FM-200 may cause frostbite if liquid discharge or escaping vapor contacts the skin.

When FM-200 is exposed to temperatures greater than 1300°F (700°C), the by-product Hydrogen Fluoride (HF) will be formed. FM-200 systems are designed to discharge in 10 seconds or less in order to minimize the amount of HF formed.

The FM-200 Material Safety Datasheet (MSDS) should be read and understood prior to

working with the agent.

A cylinder containing FM-200 should be handled carefully. The anti-recoil safety device must be in place at all times when the cylinder is not connected to the discharge piping and restrained.