- Home

- Companies

- Sauereisen Inc.

- Products

- Sauereisen - Model 33 - Acid-Alk Cement ...

Sauereisen - Model 33 -Acid-Alk Cement Mortar Grade

Sauereisen Acid-Alk Cement 33 – Mortar Grade is the original one-part, chemical-setting, inorganic, modified silicate base cement. Supplied in powder form, 33 – Mortar Grade is mixed with potable water.

Physical properties were determined on specimens prepared under laboratory conditions using applicable ASTM procedures. Actual field conditions may vary and yield different results; therefore, data are subject to reasonable deviation. Data should not be used for specification purposes.

Acid-Alk Cement Mortar Grade is specifically formulated to be used as a mortar in acid brick construction but may be placed as a castable in monolithic applications. 33 – Mortar Grade resists most acids (except hydrofluoric and acid fluoride salts) and some alkalies from pH 0.0 to 9.0. It also resists water, steam and weather without any special post cure treatment or acid washing.

33 – Mortar Grade cures with an internal chemical-setting action, developing a final set in 36 to 48 hours at 70°F. It does not have the fast initial set characteristic of most chemical-setting cements and permits economical and efficient construction.

- Resists most solvents, oil and acids (except fluorides) over a pH range of 0.0 to 9.0.

- Resists water, steam and weather without special treatment.

- Withstands temperatures to 1,750°F (954°C).

- Single component, simply mix with potable water – does not require any special binder.

- Noncorrosive – may be used in direct contact with steel, iron, lead and most other materials.

- Highly resistant to sulfation, blooming and efflorescence.

- Bonds to steel, concrete, brick and most other surfaces that are structurally sound, clean and free of oil and grease.

- Safe to use – does not emit noxious or hazardous fumes or odors during mixing, application or setting.

- Bond strength (ASTM C-321): 300 psi (21.1 kg/cm2)

- Color: Off white

- Compressive strength (ASTM C-579): 3,500 psi (246.1 kg/cm2)

- Coefficient of thermal expansion: 12.4 x 10-6 in/in/°F (22.3 x 10-6 cm/cm/°C)

- Density (ASTM C-905): 130 pcf (2.08 gm/cm3)

- Maximum service temperature (ASTM D-648): 1,750°F (954°C)

- Mix ratio (Powder:Water, by weight): 5.5:1

- Modulus of elasticity (ASTM C-580): 1.4 x 106 psi (9.84 x 104 kg/cm2)

- Recommended pH range for use: 0.0-9.0

- Shrinkage (ASTM C-531): 1.25%

- Tensile strength (ASTM C-307): 300 psi (21.1 kg/cm2)

- Thermal conductivity (C-1117): 4.8-3.7 BTU in/ft2 hr °F, (1.27 x 10-3 - 1.65 x 10-3 Cal cm/cm2 sec°C)

Physical properties were determined on specimens prepared under laboratory conditions using applicable ASTM procedures. Actual field conditions may vary and yield different results; therefore, data are subject to reasonable deviation. Data should not be used for specification purposes.

Temperature of Working Area

Maintain a temperature of 70o - 100oF on air, substrate, potable water for mixing, No. 33 - Mortar Grade, and masonry units during mixing, application, and cure.

At temperatures below 70oF, the viscosity increases, application becomes more difficult and curing is retarded. No. 33 - Mortar Grade can be applied to surfaces at temperatures as low as 60oF; however, curing is retarded. Consult Sauereisen for recommendations.

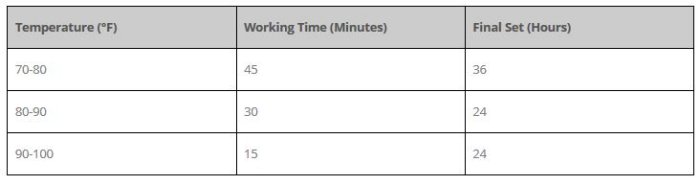

Above 80oF, working time of the material decreases. This can be overcome by mixing in a cooler area, cooling the mortar mixing equipment with ice water and/or cooling the potable water prior to mixing.

Surface Preparation

All surfaces in contact with No. 33 - Mortar Grade should be clean, dry, and free of dust, dirt, grease, oil, and other contaminants. Surface preparation should be in accordance with membrane requirements.

Mixing

Mixing should be done mechanically with a slow-speed mortar mixer. The mixing equipment must be clean and free of Portland cement or other contaminants. The size of the batch will be governed by the area to be covered, the number of workers applying the material, and the speed with which it can be placed.

Powder: Water (Parts by weight) - 5.5:1

Weigh a convenient amount of No. 33 - Mortar Grade Powder into a container and the appropriate amount of potable water into a second container. Mark the levels of each container so that succeeding measurements can be made by volume; thus eliminating the necessity of weighing each batch.

Pour the entire amount of potable water into the mortar mixing equipment. Add the No. 33 - Mortar Grade Powder slowly to the water, mixing continuously to reduce the entrapment of air. Mix thoroughly for at least 5 minutes until cement is a uniform, smooth consistency.

Material which has begun to set cannot be retempered and must be discarded. Never add water or other materials to mixed material or any component part.

Installation

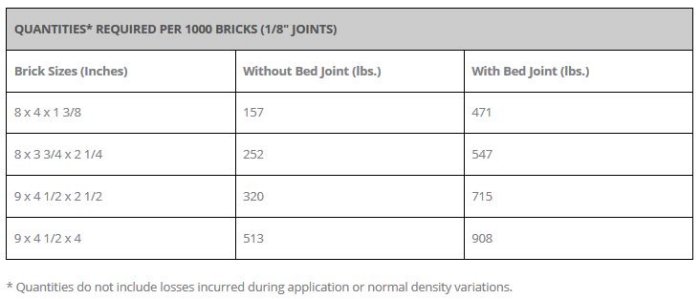

Trowel on an average 1/8-inch thick bed joint of 33 - Mortar Grade directly on top of membrane or preceding course of brickwork. Apply the mortar by buttering on side and one head joint of each masonry unit. Set the masonry units in place and position by tapping to form an average 1/8-inch wide vertical joint.

Strike extruded mortar off the face of the masonry unit with a trowel.

All equipment should be cleaned by scrubbing with a stiff brush and water at the end of each working period, or when

buildup becomes pronounced. If removal is required after cure, consult Sauereisen for recommendations.

33 - Mortar Grade is self-hardening due to a chemical reaction which occurs when the Powder and water are mixed together. An initial set occurs in 30 to 45 minutes; the final set is achieved in 24 to 36 hours depending on temperature. No acid wash is required. Brickwork should not be subjected to water, steam or chemical environment before mortar is

completely cured.

For installations that will be exposed to temperatures above 200°F, a controlled drying cycle is required to ensure that all moisture is forced out of the lining prior to placing the unit in service. This controlled drying cycle requires that 33 – Mortar Grade be allowed to dry for a 24-hour period after completion of the application.

Temperature on the surface of the 33 - Mortar Grade should be raised to 120°F and held for a period of 6 hours. At the end of the 6-hour period, the temperature should be raised to a maximum of 220°F, and held at that temperature for a 12-hour period. The temperature should be then be elevated to the unit`s maximum temperature, at a rate not to exceed 100°F per hour. The unit can then be placed in service.

50 lb. moisture-resistant bags on plasticwrapped pallets.

Sauereisen 33 - Mortar Grade Powder has a shelf life of six (6) months when stored in unopened, tightly sealed containers in a dry location at 70°F. If there is a doubt as to the quality of the materials, consult a Sauereisen representative.

Consult Safety Data Sheets and container label Caution Statements for hazards in handling these materials.

We warrant that our goods will conform to the description contained in the order, and that we have good title to all goods sold. WE GIVE NO WARRANTY, WHETHER OF MERCHANTABILITY, FITNESS FOR PURPOSE OR OTHERWISE, EXPRESS OR IMPLIED, OTHER THAN AS EXPRESSLY SET FORTH HEREIN. We are glad to offer suggestions or to refer you to customers using Sauereisen cements and compounds for a similar application. Users shall determine the suitability of the product for intended application before using, and users assume all risk and liability whatsoever in connection therewith regardless of any suggestions as to application or construction. In no event shall we be liable hereunder or otherwise for incidental or consequential damages. Our liability and your exclusive remedy hereunder or otherwise, in law or in equity, shall be expressly limited to our replacement of nonconforming goods at our factory or, at our sole option, to repayment of the purchase price of nonconforming goods.

- Distributors and agents in major cities throughout the world. Consult manufacturer for locations.

- Information concerning government safety regulations available upon request.

- Sauereisen also produces inorganic compounds for assembling, sealing, electrically insulating and grouting