- Home

- Companies

- EssDe GmbH

- Products

- S::Select - Activated Sludge Systems

S::Select - Activated Sludge Systems

| The settling of the activated sludge and thus the sedimentation rate is the central design and operating parameter for the activated sludge. S::Select ® accelerates the sedimentation of the sludge and drastically relieves the burden in the secondary clarification. Bulking sludge no longer occurs and sludge thickening is significantly improved. Further effects of the more compact sludge are a denser flake filter, which noticeably reduces the solids in the secondary clarification process. |

S::Select- significant increase in the performance of biology

S::Select specifically produces aerobic granules and permanently maintains the optimal sludge properties. The cleaning process is thereby sustainably stabilized and the nitrification performance is significantly increased while at the same time maintaining a high denitrification potential.

For example, the Glarnerland sewage treatment plant:

More municipalities will be connected in Glarnerland in the near future, which will lead to a significant increase in load (30%). In addition, the system has suffered from expanding sludge (ISV up to 800 ml/g) for decades, especially in the winter months. After S::Select ® was successfully implemented, the planned expansion from 4 to 6 streets was canceled. In addition, 2 of the existing 4 roads were decommissioned. Despite the significant increase in load (more than doubled), the drainage quality has improved significantly (suspended solids 3 -5 mg/l, visibility >=2.0 m).

In contrast to conventional activated sludge systems with suspended, flaky sludge or carrier-based systems (such as fluidized beds), S::Select ® is an activated sludge process with Aerobic Granular Sludge (AGS) (Pat.pending):

For granulation, the initially flake-like biomass is encouraged to form a biofilm. The usual flocculent sludge structure changes to an aerobic granular sludge structure (AGS) and the sludge settling properties are drastically improved. Thanks to the S::Select ® technology, the structure of the aerobic granular sludge (AGS) is permanently preserved. The specific cleaning performance (kg/kg) improves significantly (nitrification).

The sludge settles much faster (> 3 m/h guaranteed). The tank volumes of activation and secondary clarification tanks can be chosen correspondingly smaller. At the same time, the specific sludge activity also increases significantly.

In addition to the nitrification capacity, the denitrification capacity also increases significantly. This in turn leads to a high recovery of alkalinity, a stable flake structure, a low suspensa concentration and a very good visibility depth.

Filamentous organisms are part of the flakes and provide high performance due to their large specific surface area. Together with the granules, they form the much-cited dense sludge bed in the secondary clarification, which has a significant filtering effect and ensures extremely low suspensa values, but settles quickly at a high sedimentation rate.

- Significant increase in the performance of biology (possibly avoiding new construction measures to expand a sewage treatment plant)

- Avoidance/reduction of floating sludge and expanding sludge problems

- Reduction of sludge drift and reduction of residual suspension in the drain

- Reduction of particulate-bound phosphates

- Sludge settling speeds > 3 m/h

- Improving sludge thickening while reducing polymer consumption

- Excellent mud indices

- Stabilization of biological processes, especially stable nitrification

- Establishing specialized bacteria to break down hard-to-break down COD

- can be integrated into the existing system easily (without structural measures) and quickly (implementation within a few weeks).

- Extremely economical

Our selectors are designed with the experience of many years of operation and are made of high-quality stainless steel and welded according to DIN. The robust design with quality components ensures low-maintenance continuous operation.

Our employees work with customers to find the optimal integration into the existing process and provide intensive support during the commissioning and implementation phase. In addition, our team is also available to address any concerns after the process has been successfully integrated.

Bulking sludge problem

The activated sludge process is used in the vast majority of biological sewage treatment plants (>= 90%). The settling properties of the activated sludge are crucial for the dimensioning and function of the activated sludge.

Since the demand for biological nitrogen elimination in the 1980s and the correspondingly high sludge age and the associated massive expansion of the facilities, the problem of expanded sludge has arisen. Approximately 65% of all biological sewage treatment plants today suffer from severely impaired sludge settling properties at least for a few months of the year.

Bulking sludge is the excessive development of filamentous organisms. The filamentous organisms cause a very voluminous sludge, which is difficult to settle. As a consequence, the activated sludge plants have to be larger and the operational problems are enormous.

The reason for the growth of the filamentous organisms lies primarily in the significantly lower supply of nutrients as a result of the significantly larger tank volumes. With their specifically large surface area, the filamentous organisms have better access to the remaining substrate and can therefore establish themselves strongly compared to “normal” organisms. The result is expanded sludge.

The light sludge is discarded via the upper reaches as excess sludge. With the operation of the selector, in which a series of cyclones are combined, both the granules are washed and the suspended sludge is removed.

This means that two completely different sludge ages can be set within a biological system:

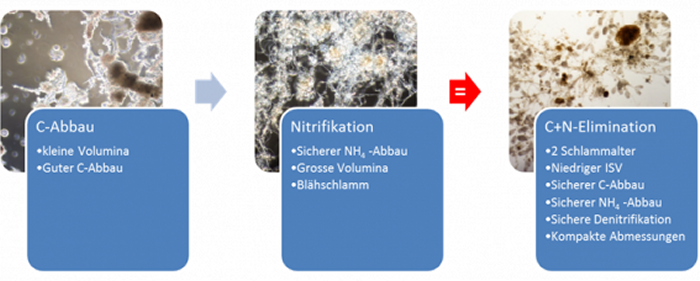

- a short flake sludge age that has a very high biological activity (C degradation, denitrification) and at the same time shows no trend towards the formation of expanded sludge (e.g. 3 days)

- a high sludge age that occurs on the granules and results in a high nitrification capacity (e.g. 10 days).

The advantages are:

- high specific biological activity with regard to nitrification and C degradation

- safe nitrification even at low temperatures

- high denitrification potential, large recovery of alkalinity and energy

- low level of stabilization and therefore high gas yield

- compact design