- Home

- Companies

- Johnson Matthey

- Products

- Active Systems - Active DPF ...

Active Systems - Active DPF Regeneration

Active DPF Regeneration. Any application in which it cannot be guaranteed that the exhaust gas conditions will be suitable for a passively regenerating system will require some active regeneration. Even in these cases, it is desirable to maximise the amount of passive regeneration that can be achieved since passive regeneration is `free`, requiring no additional energy.

Almost all active filter regeneration techniques operate by raising the temperature of the filter to around 600°C. As described in the DPF regeneration section, this is the temperature at which the particulate (PM) collected in the filter will combust rapidly in oxygen.

Combustion of HC over a catalyst

The CRT and CCRT systems can form part of actively regenerated DPF systems in which the HC content of the exhaust stream is periodically enriched, either by in-cylinder post injection or by direct injection of fuel into the exhaust stream. The HC is burnt over the catalyst, raising the temperature of the DPF to combust the collected PM.

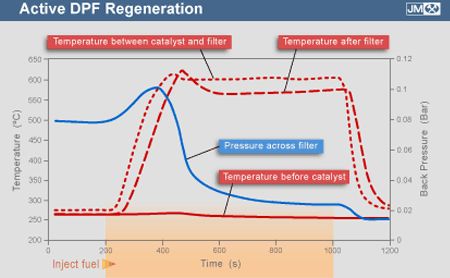

In the chart below, we show this process and its effects. In the chart, the red lines are temperatures measured in a CRT system before the catalyst, between the catalyst and the filter, and after the filter. The temperature is shown on the left-hand y-axis. The blue line shows the pressure drop over the filter, which is an indication of the amount of particulate it contains. The pressure drop is shown on the right-hand y-axis.

0 – 200 secs:The temperature throughout the system is around 260°C and the back pressure is 80mbar.

200 – 400 secs:When diesel fuel is injected upstream of the catalyst, the temperature before the catalyst remains constant but the temperature after the catalyst and after the filter rises steeply towards 600°C. The back pressure also increases as a result of the increased gas flow caused by the fuel combustion over the catalyst.

400 – 1000 secs:As the temperature in the filter reaches 600°C, the pressure falls sharply as the soot in the filter is burn away. As can be seen from the blue line, this process is largely completed in the first 200 seconds.

After 1000 secs:After the injection of fuel is stopped, the temperature throughout the system quickly returns to below 300°C and the back pressure effect caused by the combustion of the fuel stops.

Johnson Matthey has developed a range of catalysts specifically for this type of system.

These systems require careful control of the HC enrichment of the exhaust stream and are therefore much more suitable for OE applications than for retrofit systems.