- Home

- Companies

- Attolight AG

- Products

- Attolight Mönch - Add-on System for TEM

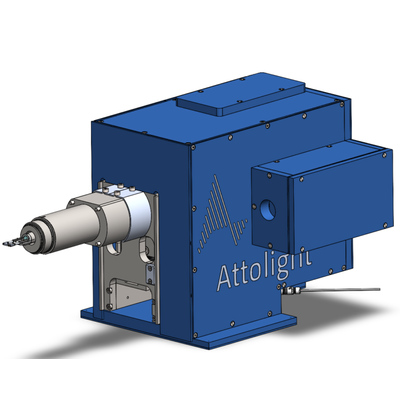

Attolight Mönch - Add-on System for TEM

The Mönch add-on is a specialized tool designed for transmission electron microscopes (TEM) that offers dual functionality in both light collection and light injection modes. Equipped with a unique mirror design, the Mönch allows for external coupling via either free space or optical fiber. In light collection mode, the system boasts an exceptional signal-to-noise ratio, leveraging features like a motorized arm with a 30mm X travel, a highly reflective mirror, and an optimized module. In light injection mode, it enables superior performance levels, facilitating electron imaging and light emission post-light or thermal excitation. This add-on is particularly effective for applications in semiconductors, time-resolved cathodoluminescence (CL), monolayers, and plasmonics. The proprietary reflective mirror is held by a retractable arm, ensuring independency from the sample holder while maintaining a low mirror-sample distance. With its patented asymmetric fiber, the Mönch stands out in both academia and industry for cutting-edge research.

The Mönch add-on is a unique tool that can operate in either a light collection or light injection mode, thanks to its specific mirror design. In addition, the flexibility of the add-on allows an external coupling either in free space or via an optical fiber.

In light collection mode, the Mönch add-on has been designed to achieve an unprecedented signal-to-noise ratio thanks to:

- A proprietary collection mirror with a curvature radius that fits in a small pole piece gap (down to 5mm) and a precise sub-micrometer alignment for a perfect adjustment of the mirror with respect to the sample.

- A working distance reduced to 300µm to optimize light collection efficiency

- A patented asymmetric optical fiber designed to preserve brightness and spectral resolution.

In light injection mode, an unprecedented level of performance is reached thanks to:

- A beam size reduced to few microns for localized excitation of your samples. Light injection can be operated to locally heat specific areas of the sample surface.

- The ability to perform injection and light collection measurements simultaneously.

Mirror independent from sample holder

- Flexibility, ease of alignment vs. e-beam and sample

- Free sample displacement (enables to scan a large sample surface)

- High curvature parabolic mirror (NA>0,4)

Motorized arm (X travel 30mm)

- Fine alignment (precision better than 100nm)

- Full retractation arm to enable EDX, EELS, 4D-STEM… analyses

Low mirror-sample distance

- Maximize light collection/injection

- Spot size down to 2µm-diameter

High mirror reflection

- Up to 90% from 200nm to nIR.

- Various mirror coatings available (ex: Gold coating for l>1.7µm)

Optimized module

- User-proof actuation system with absolute encoders (position recovered after power cut-off without need for calibration)

- Stage touch alarm

- Compatible with 120°C system vacuum bakeout

- Compatible optical fiber or free space (switch takes few seconds)

Collection mode

- Free space or through a fiber

Patented asymmetric fiber

- Fibers arrangement parallel to the entrance slit of the imaging spectrograph

- Brightness and spectral resolution are preserved

- Study of advanced materials, such as:

- Nitrides (GaN, InGaN, AlGaN, …);

- III-V (GaP, InP, GaAs, …);

- II-VI (CdTe, ZnO, …)

- Wide band-gap materials (diamond, AlN, BN)

- Compositional inhomogeneities in compound materials (e.g. Indium clustering in InGaN)

- Confined structures or heterostructures morphology to their optical properties

- Defects (vacancies, threading dislocations, stacking defaults, …)

- Plasmonics …