Aerosol Devices - Model 110 Series - SSS110A -Sequential Spot Particle Sampler

The Series 110A Sequential Spot Sampler instrument enables affordable, time-resolved characterization of particulate chemical composition at multiple locations. It provides an uninterrupted collection of particulate matter (PM) as concentrated dry deposits into small sample wells. PM deposits can be analyzed directly using spectrographic methods, or extracted for wet chemistry analysis.

- High collection efficiency from 5 to >25,000nm

- No particle bounce

- Captures soluble and insoluble particles

- Moderate temperatures (25-30̊C) for condensational growth

- No steam injection required

- Subsaturated outlet flow at room temperatures

- User-selected sampling intervals from 1 minute to 24 hours

- Particles concentrated as a 1-mm “spot” in a sample well are ready for analysis

- User-selected well temperature to evaporate water

- Sample plate may be made from a variety of solid materials

- Sample plate may be cleaned and reused

- Interface with a PAL3 autosampler for automated chemical analysis

- Each well can be sampled directly into for later elution and extraction of sample

- Samples can be deposited directly onto a variety of solid, removable substrates inserted into each well.

- 5-mm diameter substrates fit perfectly into the bottom of the wells

- Substrates include glass (microscope coverslips), filter, aluminum foil and many more!

- Sample plates can held in an tray for automated sample preparation and extraction using the PAL3 Autosampler

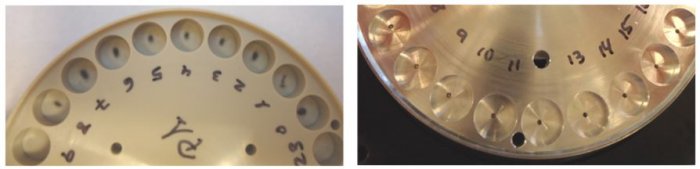

32 well plate with circular well shape

- Available in Aluminum or PEEK

- 6 mm in diameter wells

- Each well can hold up to 70 µL liquid for elution

32 well plate with teardrop well shape

- Available in PEEK

- 6 mm in diameter

- Each well can hold up to 120 µL liquid for elution

- Well shape for easy removal of solid substrates

The Spot Sampler™ particle collectors use well-known laminar-flow water condensation technology and gentle impaction for wet or dry collection. The inherently pre-concentrated particle samples are ready for laboratory chemical or biological analysis.

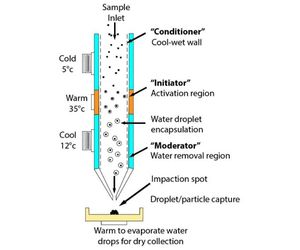

Aerosol particles enter the collector where they are exposed to a supersaturated water vapor environment. A moderated 3-stage growth tube consists of three temperature regions to control the vapor profile.

Conditioner

The initial cold “conditioner” establishes a controlled vapor saturated aerosol stream largely independent of the incoming sample flow conditions.

Initiator

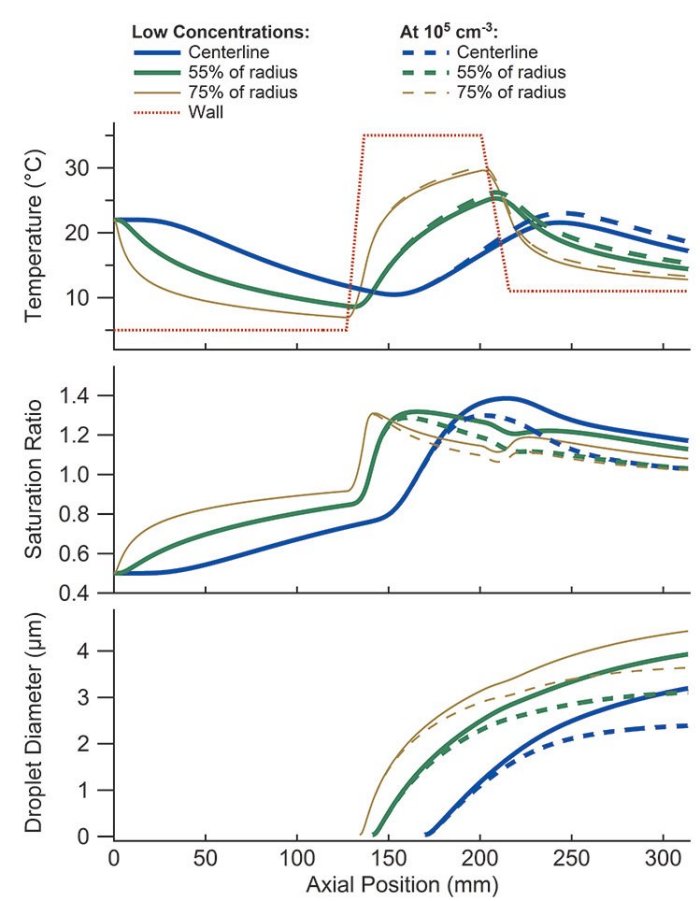

Supersaturation occurs in the second region as a result of the difference in the diffusive rates of water vapor and heat transport. The warm walls of the “initiator” provide a region high of partial pressure of water vapor. Because the mass diffusivity of water vapor is larger than the thermal diffusivity of air, the water vapor diffuses into the flow faster than it warms. To reach a desired state of equilibrium, the supersaturated air condenses water vapor on the tiny “seed” particles. The relative humidity in the initiator reaches values of 130-140% which is enough to overcome the surface energy associated with the curvature of the particle surface, and activate condensational growth of particles as small as 5-10nm diameter. The particles are enlarged into water droplets ~ 3µm diameter effectively forming a fog.

Moderator

The final cool “moderator” region allows continued droplet growth while reducing the flow temperature and water vapor content. This lowers the vapor content below saturation levels at ambient conditions and avoids unwanted condensation downstream of the collection region. Droplet growth occurs at temperatures close to ambient (25-30ºC in the flow stream) providing robust collection for volatile constituents, reducing changes in the particle chemical composition, and maintaining microorganism viability.

Collection Well

The water-encapsulated particles gently impact onto the warmed surface of a 75µL collection well, whereby the water evaporates and leaves a dry, 1-mm diameter “spot” of particles. Heat applied to the collection well is user adjustable to accommodate the collection objectives and heat transfer rates of the various sample plate materials. A single wetted-wick is easily removed and replaced from the top of the growth tube.

A stepper motor at the base of the growth tube rotates a multi-well plate for time-resolved sample collection. Users can program the instrument to advance to a new collection well at defined intervals providing a set of 30 uninterrupted, time-resolved samples, plus blanks and a set-up well. The collection plate is easily transported back to the laboratory for analysis while the instrument remains in the field ready to collect new samples.

For wet chemical analysis, the multi-well sample plate is placed directly into an autosampler, without requiring user extraction or preparation. The autosampler adds extraction solvent and handles mixing, extraction, and sample injection into the analytical system without requiring any user manipulation. A single analytical system (such as an ion chromatograph, IC, or high-performance liquid chromatograph, HPLC) can be used to analyze samples from multiple particle collectors. Sample plates can be cleaned and reused.

For collection into liquids, the water-encapsulated particles exiting the growth tube are directed through three nozzles into a small vial containing 0.5ml of liquid. Droplets gently splash impact with the liquid surface. The particles are efficiently captured into the liquid suspension without break up, liquid spray, or re-aerosolization. The mild turbulence created in the liquid mixes the particles throughout the suspension. Inlet and exit ports on the vial allow users to configure the sampling for semi-continuous chemical analysis.

Several sequential Spot Sampler prototypes were tested in the field and compared to standard filter collection methods and near-real time instruments. Hourly ambient PM2.5 samples were collected for inorganic anion measurement and the results compared well with those obtained using a Particle-into-Liquid System (PILS) and URG-filters. Particle-bound polyaromatic hydrocarbons (PAHs) were also measured with 12-hr time resolution for an uninterrupted period of 4 months. Ambient particle concentrations measured with prototype samplers compared well with those obtained using standard Teflon® filters. See the Reference section for publications and presentations that document the collector development and field test results.

Spot Sampler Particle Collector Advantages

- Patented water condensation technology for high collection efficiency: Dry collection efficiency of >95% for particles 5nm to 2.5µm; >90% for wet collection up to >10µm. No particle bounce. Captures both soluble and insoluble particles. High collection efficiency in concentrated samples allows for quantitative analysis of elemental/chemical constituents.

- New three-stage condensation technology with no heating of the air flow (patent pending): Particle growth activation is achieved at temperatures close to ambient (25-30̊C) minimizing loss of semi-volatile compounds and reducing thermal decomposition. Gentle heating of the collection well for a limited duration evaporates the water without volatilizing the dry deposited material.

- Sequential, uninterrupted, time-resolved sampling for dry particle collection: Allows for better assessment of temporal variability with user-selectable resolution from minutes to hours. Better time resolution improves the correlation between exposure levels and health/environmental effects, emission sources and ambient concentrations, and the effect of photochemistry in diurnal patterns.

- Concentrated sample deposition: Dry particle deposits are concentrated in a 1-mm diameter area within a 75µL collection well. Concentrated particle suspensions are in 0.5 mL of liquid. Small volume extraction of concentrated samples improves analysis Limit of Detection (LOD) and Limit of Quantitation (LOQ).

- Elimination of laboratory sample handling: Using a PAL3 autosampler as the interface between the sample plate and analytical instruments (e.g. IC, HPLC) eliminates the need for manual sample preparation steps such as sample cleaning, extraction and preconcentration typical of filter sampling. This significantly improves data quality and reduces the cost, time, and labor of chemical characterization.

- Low acquisition and operating cost: Comparable in price to a basic filter sampler with pump, and up to 90% less expensive than an automated chemical particle analyzer. One analytical system can service multiple collectors. After analysis, collection plates and vials can be cleaned and reused.

- Sample plate options: Users can select sample plates in a variety of configurations and materials optimized for the chemicals of interest and analytical technique. A multi-well sample plate made from PEEK® polymer is ideal for IC and HPLC analysis. Various substrates (for example, filter or foil disks) can be inserted into the individual wells providing a removable collection surface to accommodate analytical techniques such as thermodesorption GC-MS, ICP-MS, OC/EC and spectroscopic methods.

- Particle Size Range

- 5nm to >2.5μm dry collection;

- 5nm to >10μm wet collection

- Collection Efficiency

- >95% for dry collection;

- >90% for wet collection

- Condensing Fluid: Water, distilled or cleaner

- Wick Material: DVPP00010 Durapore Membrane Filter (Millipore) formed into a 30 cm long (6.35 mm OD x 4.8 mm ID) roll

- Sample Flow Rate: 1.0 – 1.5 L/min (user adjustable)

- Sample Aerosol Conditions

- Non-corrosive

- 0 – 40 degrees C

- Sequential Sampling into Multi-well Sample Plate: 32 well plates available with circular well shape (75 μL well volume) or teardrop well shape (120 μL well volume). PEEK® polymer or bare aluminum. Other materials and configurations are possible.

- Sequential Sample Time: User selectable sample time in each well from 1 minute to 24 hours

- Dry Deposition Area: Approx. 1-mm diameter

- Liquid Sampling: Flat or conical bottom collection vial made of polycarbonate. Volume of 0.65 mL for liquid or gel substrate. Flat bottom ported vial includes two M3 SS barb fittings with Nylon washer for 1.5mm ID flexible tubing (Tygon® or Teflon® recommended). Conical ported vial uses a M6 thread that accepts IDEX/UpChurch flangeless fittings. Other configurations are possible.

- Display: LCD display, 4 lines x 20 characters

- Communications: USB communications output for sampling parameters and instrument status

- Environmental Operating Conditions

- 10 – 35 degrees C

- 10 – 95% RH

- Sample Inlet: 6 mm OD SS tube

- Power Requirements: 90-264 VAC/47-63 Hz; output voltage is 12.0 V DC and output current is 15A (maximum)

- Dimensions: 50 cm (H) x 31 cm (W) x 26 cm (D) (19.5 x 12 x 10 inches)

- Weight: 6.8 Kg (15 lb) Growth Tube unit: add 1.1 Kg (2.5 lb) for Sequential Spot Collector module; add 0.1 Kg (0.22 lb) for Liquid Spot Collector module