- Home

- Companies

- Aquaconsult Anlagenbau GmbH

- Products

- Aerostrip - Model Type Q - Fine-Bubble ...

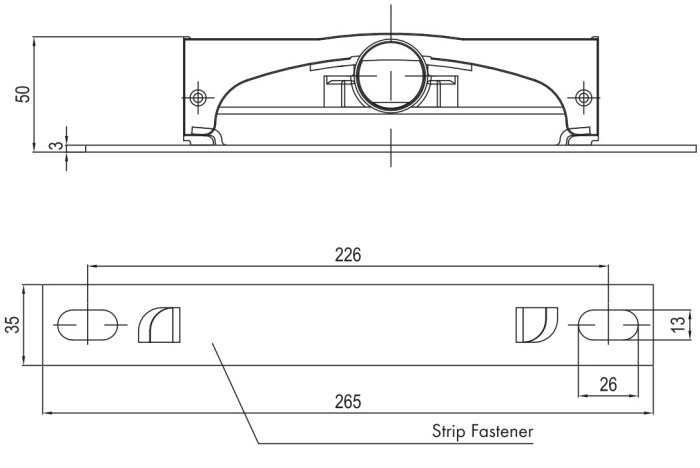

Aerostrip - Model Type Q -Fine-Bubble Diffuser System

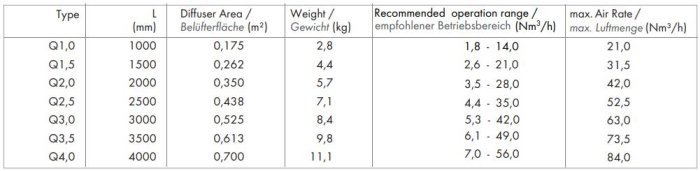

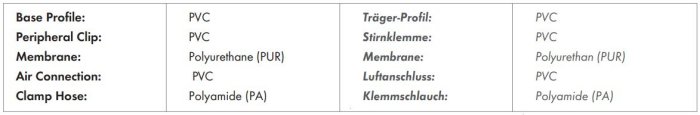

The AEROSTRIP Type Q is one of the most powerful diffusers on the market. It was designed as a fine-bubble diffuser with extremely low energy requirements and has been used in both municipal and industrial wastewater treatment plants worldwide since 2005. The basic body of the AEROSTRIPs is made of high-quality PVC. Polyurethane is used as the material for the diffuser membrane. Polyurethane has a higher mechanical strength than EPDM or silicone. This is reflected in an exceptionally long service life of up to 20 years. The AEROSTRIP Type Q has the same performance as the Type T, but impresses with its light weight, the practical horizontal air connection and an excellent price-performance ratio.

- The materials used in the strip diffuser are resistant to all those water components which, according to DWA-M 115-2 Appendix A.1. may be discharged into a biological sewage treatment plant.

- AEROSTRIP strip diffusers enable operation with very low air pressure, which significantly reduces power consumption

- The very small bubbles result in efficient oxygen transfer (SOTR) and oxygen transfer efficiency (SOTE) of up to 60%.

- No comparable diffuser currently on the market meets the different requirements of an aeration system as well as AEROSTRIP.

- AEROSTRIP Type Q is recommended for an application area <30°C.

The polyurethane membrane is perforated with needle holes to allow the supplied air to exit the diffuser body. The type of perforation has a significant impact on the operating range, i.e. the air flow rate of the aerator. With AEROSTRIP® diffusers you can choose between different types of perforation.

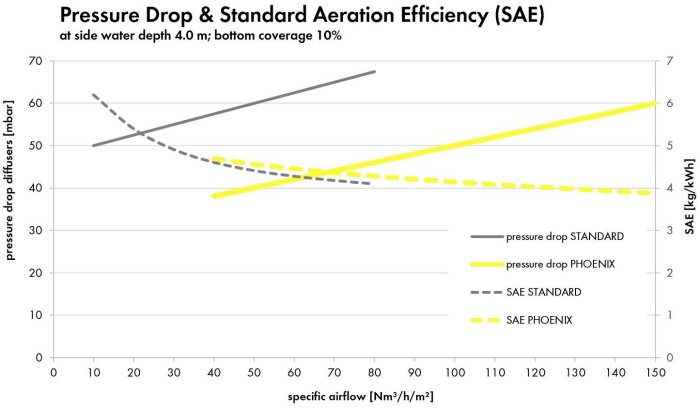

The “STANDARD” perforation has slightly smaller holes but a higher number of holes (approx. 400,000 holes/m²). It is particularly suitable for operation with low to medium specific airflows and achieves very high values for oxygen uptake (SOTE) and oxygen yield (SAE).

The “PHOENIX” perforation has slightly larger holes but a smaller number of holes (approx. 133,000 holes/m²). This results in a lower pressure loss and allows an efficient working range with specific airflows above 40 Nm³/h per m² of membrane area.

- fine bubble diffuser with extremely low energy consumption

- up to 20 years lifetime for progressive sustainability

- efficient oxygen transfer for optimal wastewater treatment

- since 1995 successfully used by more than 2.500 systems

- development from pioneer to global leader

- low-maintenance and reliable in use

- conventional activated sludge process (Plug flow, fully mixed, circulating tanks, single and multi-stage…)

- activated sludge process - intermittent operation (SBR, CSBR, Triple-A)

- activated sludge process with high amount of solid matters (MBR)

- granulated sludge process (Nereda)

- combination of fixed bed and activated sludge (IFAS)

- floating fixed bed (MBBR)

- nitrogen decomposition – deamonification process (DEMON)

- oxygen transfer efficiency (SOTE) up to 60%

- standard aeration efficiency (SAE) from 4 - 6 kgO2/kWh

- wide range of application from 5 - 150 Nm³/h/m² diffuser area

- optimal perforation for every application

- lowest flow resistance due to flat design and installation on the pool floor

- low maintenance effort

- membrane lifetime up to 20 years

- low costs due to high efficiency