- Home

- Companies

- AES Aritma

- Products

- AES - Solid and Liquid Separation ...

AES - Solid and Liquid Separation System

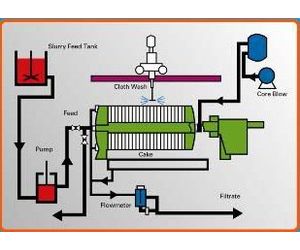

Economic and efficient solutions for all filtration problems from 5 liters to 18 m3 cake capacities. Filterpresses met the industry in early 1900`s and started to be used extensively in sludge dewatering (decomposition of solid and liquid). Previously used only labor intensive, this equipment, changed its image as of 1960`s and took its place in industry by various automotions. They have become the indispensable equipments of the plants having been donated by washing, drying, automatic discharge mechanisms in order to make out a cake as dry as possible.

Filterpresses are made up of two fixed heads an done moving head compressing the plates. One of the fixed heads carries the hydraulic group compressing the plates, the other one carries the sludge etrance system. The plates are carried by the help of side beams between the twp fixed heads or the overhead beams. Each filtration plate is dressed by filter cloth on both sides. Filtration chambers with different plate numbers have been formed when the pres worked and plates are collocated.

The most widespread type of plate use is the one that is centrally supplied. This supply goes on all along the plates and thus homogeneous fill of all the chambers is provided. Discharge bips located at the very bottom of the plates, is one of the most widespread "Open Discharge" application making the filtrate bip pot to the required location. Besides, close discharge system is widely used in toxic, flammable and evaporating filtrates.

Two types pf plates are used in filterpresses; one with a membrane an done without a membrane. In both plate types, the filtration principle is as seen in the below scheme.

Filterpresses Without Membrane Plates

- Sludge is pumped to the chambers from sludge etrance by the help of a pump. Formation of a cake which gradually gets thicker starts in the chambers. The cake, getting drier as the pressure increases, gets the intended formation.

- In order to increase cake`s dryness, air is blown from the center. Sludge at the supply is discharged with this air to obtain a completely dry cake.

- Press is opened.

- Plates are opened particularly and the cakes are emptied.

- The filterpresses are ready to a new cycle.

- Sludge is pumped to the chambers from the sludge entrance by the help of a pump. Formation of a cake which gradually gets thicker starts in the cells.

- In the meantime, special membranes in the form of an empty chamber stick to the plate completely.

- Pre pressing is realised by applyling presure to the membranes when the chamber pressure reaches up to 6-7 var.

- In order to obstruct cake hold, cake is washed with water in this position.

- Air blowing is applied to reduce cake moisture.

- More water or air is pumped to the backside of the membrans for final squeezing up tp 15 bars to further reduce moisture.

- In order to get rid of the wet liquid in the sludge, central blowing processing is done. Thus the cake to be emptied is completely dried.

- Press is opened.

- Paltes are opened particularly and tha cakes are emptied.

- The filterpresses are ready to a new cycle.