Ağaçlı Silo A.Ş.

- Home

- Companies

- Ağaçlı Silo A.Ş.

- Products

- Agacli - Air Duct

Agacli - Air Duct

FromAğaçlı Silo A.Ş.

The ventilation area required for silo ventilation is calculated according to the stored product and ventilation speed. Different types of ventilation ducts are used for sufficient ventilation area. Channel height varies depending on ventilation channel widths. Ventilation channels are opened into the silo foundation concrete. Depending on the ventilation width, support legs can be mounted under the ventilation grilles. The ventilation ducts are covered with ventilation grilles. Ventilation grill holes are produced as perforated or shutter type according to the characteristics of the grain stored.

Most popular related searches

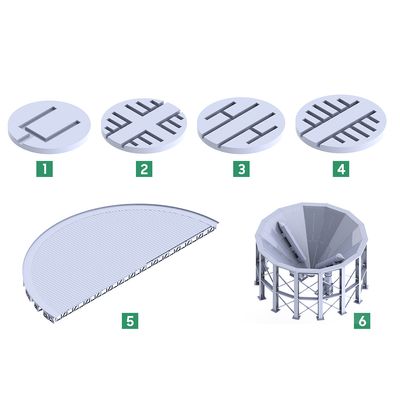

1) Y Model Ventilation Duct

- If a fan is required to adequately ventilate the grain stored in the silo, Y type ventilation duct is used.

- It is generally preferred in small diameter, low-rise silos.

- Application is made in different channel widths and heights.

2) H Model Ventilation Duct

- If two fans are required to adequately ventilate the grain stored in the silo , H type ventilation duct is used.

- It is generally preferred in small diameter, low-rise silos.

- Application is made in different channel widths and heights.

3) I Model Ventilation Duct

- If two or more fans are needed to adequately ventilate the grain stored in the silo , type I ventilation duct is used.

- The air distributed from the main branch is divided into side branches, providing equal ventilation in the silo.

- The main ventilation arm varies depending on the number of fans.

- Side ventilation arms may have different numbers depending on the ventilation area.

- It is preferred in silos where ventilation duct space is required.

- Application is made in different channel widths and heights.

4) F Model Ventilation Duct

- If four fans are needed to adequately ventilate the grain stored in the silo , an F type ventilation duct is used.

- The air distributed from the main branch is divided into side branches, providing equal ventilation in the silo.

- Side ventilation arms may have different numbers depending on the ventilation area.

- It is preferred in silos where ventilation duct space is required.

- Application is made in different channel widths and heights.

5) Full Ventilation

- For the grain stored in the silo , if the ventilation channel area to be opened into the concrete does not meet the required ventilation area, full ventilation is used.

- The number of fans may vary depending on the product to be stored and ventilation speed.

- Ventilation grill holes are produced as perforated or shutter type according to the characteristics of the grain stored.

- Support legs are mounted under the ventilation grills.

- It can be mounted at the level of the silo body sheet, inside the silo foundation concrete or on the side of the silo body.

- When mounted on the silo body, the silo capacity will decrease as well as the volume occupied by the ventilation.

6) Tube Ventilation

- It is preferred for ventilation of conical bottom silos.

- Ventilation tubes made of cylindrical perforated sheet metal are mounted inside the silo cone.

- Tube lengths vary depending on the silo conical length.

- The required number of ventilation tubes is determined according to the characteristics of the stored grain and the ventilation rate.