- Home

- Companies

- Flame Spray SpA

- Products

- Flame Spray - Air Plasma Spray (APS)

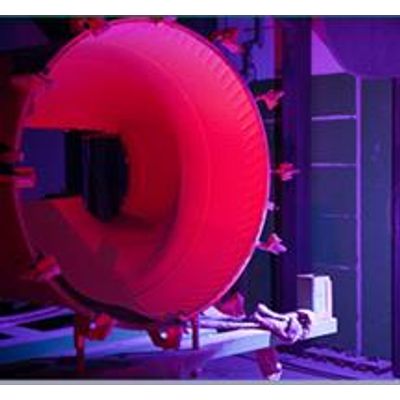

Flame Spray - Air Plasma Spray (APS)

APS is a versatile and highly efficient way to apply protective coatings to various substrates, improving surface properties and extending component life. This method is ideal for a wide range of materials and industrial applications, making it a popular option in industries such as aerospace, automotive, and power generation.

Air Plasma Spray (APS) is an innovative technique used to create protective coatings on surfaces exposed to extreme conditions.

The process uses electrical energy to ionize a stream of gas, such as argon or helium, generating a "plumb" of high-temperature plasma that reaches up to 10,000°C. This plasma heats and accelerates particles of material, often in the form of powder, which are projected at high speed onto the surface to be treated.

One of the most commonly applied materials through APS is zirconia. Due to its exceptional thermal barrier properties, zirconia is ideal for protecting components exposed to high temperatures, such as blades and nozzles in gas turbines. This material helps improve the resistance to thermal stress, increasing the life and reliability of critical components.

Another key material is chromium oxide, a high-hardness ceramic known for its tribological properties. Chromium oxide coatings offer excellent wear resistance and are used in industries where components are subjected to abrasive conditions.

In addition to zirconium oxide and chromium oxide, APS can be used to apply a wide range of materials, including:

- Tungsten or chromium carbides: Ideal for resisting abrasion.

- Aluminum oxide: Used for its hardness and corrosion resistance.

- Titanium dioxide: Valued for its thermal stability and resistance to oxidation.

- Metal superalloys: Used in applications requiring a combination of strength and durability.

Air Plasma Spray coatings offer numerous advantages that make them an optimal solution for protecting and improving the performance of industrial components:

- Thermal Fatigue and Wear Protection: APS coatings create a barrier that protects components from thermal and mechanical stress, extending their service life.

- Oxidation and Corrosion Resistance: Ideal for environments where components are exposed to aggressive chemicals or high temperatures.

- Application Versatility: Coatings can be applied to complex shapes and surfaces, providing uniform, seamless coverage.

- Durability in Harsh Environments: APS coatings are extremely durable, resisting challenging environmental conditions such as high temperatures, abrasive materials and chemicals.

Thermal Fatigue and Wear Protection: APS coatings create a barrier that protects components from thermal and mechanical stress, extending their service life.

- Power Generation: Protective coatings for gas turbines and components exposed to extreme heat.

- Aerospace: Improved thermal and mechanical properties of critical components.

- Automotive: Protection of engine components and exhaust systems against wear and corrosion.

- Petrochemical: Chemical resistance and erosion protection for equipment and pipelines.

- Transportation: Coatings for components requiring high durability in extreme operating conditions.

- Paper and Printing: Improved anti-wear properties for rollers and other surfaces in contact with abrasive materials.

Air Plasma Spray (APS) coatings are a cutting-edge solution for protecting and improving the life of components exposed to harsh conditions. Due to their versatility and the many benefits they offer, APS coatings are widely used in many industries, ensuring superior performance and increased longevity of critical components. If you are looking for a coating that offers resistance, protection and durability, Air Plasma Spray is the right choice for your industrial needs.