- Home

- Companies

- Pyro Green-Gas (formerly known as ...

- Products

- AirScience DeOxo - Process Temperature ...

AirScience DeOxo - Process Temperature Unit

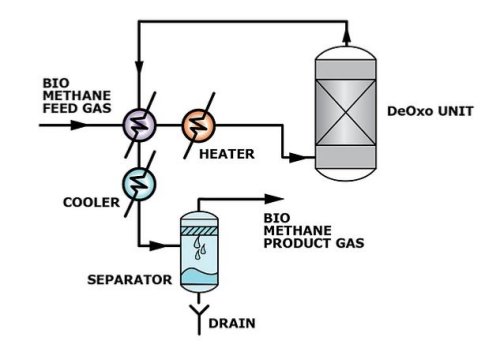

The oxidation reaction is exothermic and as the reducing agent is the quasi sole constituent of the gas, the oxidation reaction is only limited by the amount of oxygen present in the gas. As the DeOxo reaction needs a minimum temperature to proceed and the reaction produces heat, the maximum concentration of oxygen that the DeOxo reactor can accept is limited by the maximum temperature the catalyst can safely accept without any degradation. Taking into consideration the necessary safety factors, AirScience generally limits the catalyst exit temperature at 500°C (932°F).

In cases where the oxygen content is higher that a single DeOxo stage can accept, the unit will be designed with two catalyst stages with a inter-cooling stage between the two catalyst beds. In the production of sulfuric acid from hydrogen sulfide, the catalytic oxidation unit can have up to four beds, each separated by a cooling stage.

The DeOxo unit is generally followed by a thermal swing adsorption (TSA) gas dryer to remove the water vapour produced by the oxidation reaction. In the case of hydrogen production, the CO2 produced must also be removed. In the case of biomethane for pipeline injection the amount of CO2 produced is not significant enough to require its removal from the product gas.