- Home

- Companies

- Advanced Misting Systems

- Products

- AMS - Model 1000 PSI - Nylon Tubing ...

AMS - Model 1000 PSI -Nylon Tubing High Pressure Misting System

A nylon tubing high pressure misting system (1000psi) from Advanced Misting Systems can reduce the temperature of your outdoor area by 30 degrees! The biggest advantage a high pressure misting system has over a low (150psi) or mid (300psi) pressure system is that the 1000psi pump produces a water droplet that is much smaller, a smaller water droplet means the evaporation is quicker, and this equals a lower temperature drop! Our nylon tubing high pressure misting systems are premium quality and include all the parts and fittings needed for installation (see full parts lists below). Our 1000 psi misting kits are designed for easy installation, the average DIYer should have no problems with installation.

WHAT PUMP & LENGTH DO I NEED?

A big advantage of buying from Advanced Misting Systems is our experience, owner Mike has 20+ years experience with misting systems – if you have any questions don’t hesitate to call us at 760-779-1352. The steps listed below should be enough information for you to make the necessary choices to configure and purchase your high pressure misting system.

SELECT PUMP TYPE

- Direct Drive: This pump is the most cost-effective, and it gets the job done for just about every application.

- Enclosed Direct Drive: This is the same pump as the Direct Drive in an enclosing. This offers more protection and is quieter.

- Pully System is also available for an additional fee. Please call 790-496-5981 for more information and how to order.

MEASURE LENGTH

Measure the outside perimeter of the area you want to cool with a misting system. And then measure the distance from the area you want to cool, to your water/electrical source. Take the outside perimeter measurement and add the measurement to your water/electrical source, and then add roughly 10% for good measure – this total would be the length you will need to select.

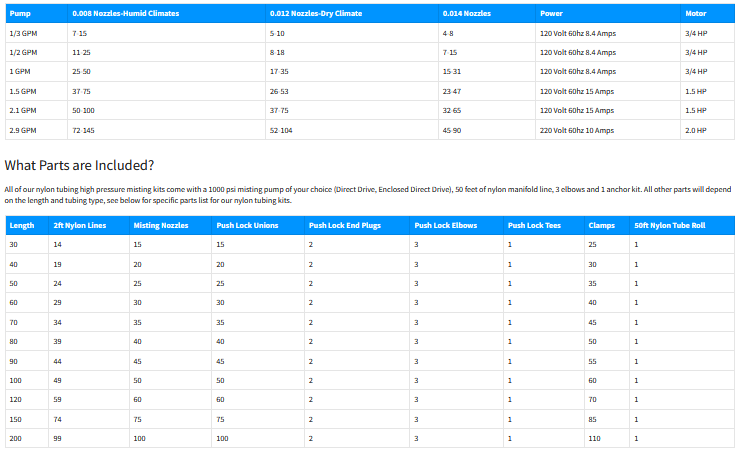

Nozzle and Motor Chart

*Pump GPM is configured by how many nozzles you are running and the orifice size of the nozzles. Take your length (linear footage) divide by 2 which will then equal how many nozzles. See below chart to determine your pump GPM.