Apex - Model XA1200 -Hydroseeders

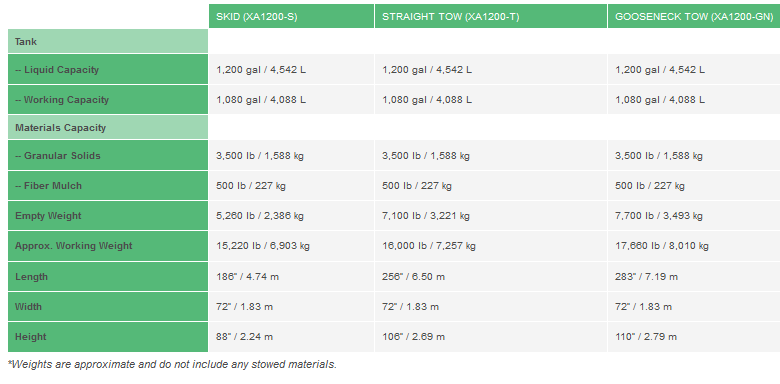

The Apex XA1200 is a mid-sized hydroseeder and is offered in three configurations: skid, straight tow and gooseneck tow.

- Tank Size: 1200 Gallons / 4542 Liters

- Material Capability: All Hydraulic Mulches - No Limitations

- Engine: Doosan D24: 74 hp / 55 kW. Turbocharged, water cooled, Tier 4 Final with self diagnostics

- Pump: 4” x 2” APEX engineered Vortex Pump, hydraulically driven with variable speed control

- Agitation: Single Shaft, 15 blades, hydraulically driven, reversible, variable speed (0-130 rpm), with liquid recirculation and APEX exclusive 5 Point Seal Assembly

- Standard Features: Stainless Steel mixing tank • Military grade aluminum tank top • Fully enclosed engine compartment with service doors • 2 large slide gates • Raised loading hatch • Modular “Power Pack” design • Bolt-on 37 Gallon (150 Liter) fuel tank • 42 Gallon (159 Liter) hydraulic tank • 34” (86 cm) Mounting rail legs for direct truck frame mounting

- Nozzles: 3 nozzles- wide fan, narrow fan & long distance

- Optional Equipment: Hose reel with 1-1/4” X 200’ (31.75 mm x 60.96 m) semi-rigid hose & remote valve

- Max. Discharge: 185 feet (57 m)

Abrasive slurry mixes won’t destroy our tank body or piping, because we’ve specially welded each tank with noncorrosive stainless steel both inside and out to eliminate weak points, maximizing the product lifespan. Additionally, we have powder coated railings and an aluminum operator platform to prevent corrosion and water collection. We’ve been in the business along time and we understand what corrosion will do. If there’s a chance the mix will touch it, we protected it.

Our twin hydraulic system features a working life of more than 2000 hours. And our advanced hydraulic cooling design prevents the system from overheating — improving efficiency and eliminating the need for a hydraulic oil cooler and its related maintenance

Our machine was created with versatility in mind so we included large pumps and agitation systems as well as variable controls for use with a wide-variety of products.

We designed our power and pump system to be completely removable allowing contractors to remove, replace or upgrade the power to extend the life of the tank and ensure consistent compliance with latest technologies and requirements.

Prepare to see high quality results as our vortex pump easily handles thick and viscous mixes without clogging, and will discharge nearly the entire tank of material with distances of more than 325 feet.