- Home

- Companies

- Aquar System Ltd

- Products

- Aquar System - Model A381 - Pulp Valve

Aquar System - Model A381 -Pulp Valve

There are some stages in manufacture where using standard devices and solutions cannot take parameters in needed range. In such way specialized equipment for specific task and condition is used.

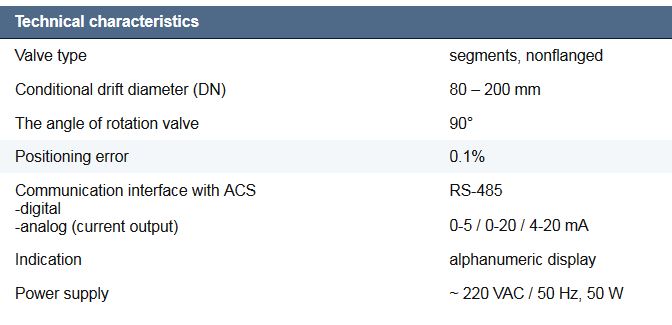

In pulp and paper industry there are number of specialized control units that demands special approach. Particularly such unit is a pulp valve A381. This valve is designed for dosing paper pulp to paper machine (cardboard machine). The advantage of this pulp valve is servo drive that allows controlling the valve position down to 0.1%, also special form of valve allows proportional controlling of paper pulp consumption depending on angle of valve opening. Valve A381 is used as a separate unit with manual control as well as a part of system pulp short circulation.

The pulp valve control unit A381 is designed for use in the pulp and paper mills in order to control the value of the paper web density reel paper machines/cardboard machines.

- The module uses segmental control valves with transmission characteristics close to linear

- Control module of pulp valve consists of two main components: executive mechanism and the control unit.

- Executive mechanism is implemented on the basis of the segmental valve, supplemented with gear, reversive type electric drive and an absolute position sensor. Mounting an absolute position sensor directly to the drive shaft of the regulating segment eliminates the effect of drive and gear backlash on the positioning accuracy.

- The control unit functions is indicating current value of the valve position, manual and automatic work mode (under control of operator workstation), setting setpoint of valve position, generating motor control signals, as well as service and diagnostic functions.