Argotech a.s.

- Home

- Companies

- Argotech a.s.

- Products

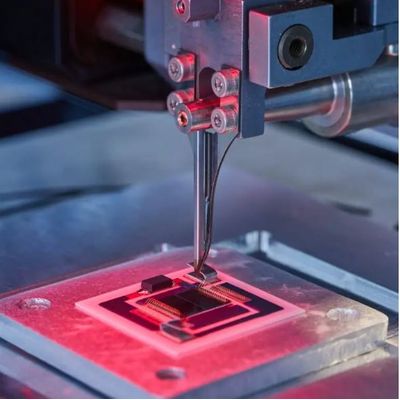

- Argotech - Wire Bonding System

Argotech - Wire Bonding System

FromArgotech a.s.

Wire bonding has been the most commonly used method for component interconnection with substrate, PCB or package module. The most standard is the ball bonding with ball/wedge method. We can process also full ball stich on ball (BSOB) or wedge/wedge method.

Most popular related searches

Every year the components get slighlty smaller, so using the 17µm gold wire we can hit the ultra-fine bond pad pitch (BPP) even under 60µm. It means that together with placement accuracy +/-3µm we are able to provide wire bonding services of the newest components including the Photonic Integrated Chip (PIC).

Parameters:

- high speed or low volume batch

- wire material: gold or aluminium

- method: Ball/wedge, BSOB, wedge/wedge, ribbon wire

- ultra-fine bond pad pitch: from 60µm

- placement accuracy: ±3µm

- pull-test and ball-shear test according to MIL standards.

Typical application:

- Wafer level – Interconnect of chip to interposer

- Component level – Interconnect of sophisticated multichannel chip on substrate layout