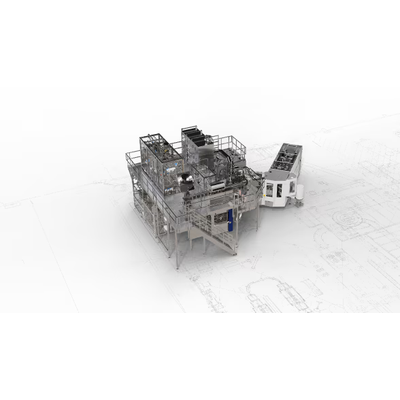

Krones - Model AseptBloc -Aseptic System

The Krones aseptic systems family includes experts for all kinds of different sterilisation methods and products to be filled. One of them is the Contipure AseptBloc. Regardless of whether you are blow moulding, filling or capping, with the Contipure AseptBloc every production step is safely included in an aseptic processing chain.

At a glance

- Design:

- Preform sterilisation module

- Aseptic blow moulder

- Aseptic filler and capper

- Suitable for:

- Aseptic filling

- Round, square and rectangular PET containers

- Standard and lightweight containers

- Output: Up to 72,000* containers per hour

- Compact variant: 8,000 to 27,500* containers per hour, for non carbonated beverages

- Only one sterilisation medium: gaseous hydrogen peroxide (H2O2)

The all-round treatment with gaseous H2O2 sterilises the entire preform surface at once: Inside, outside and in the neck area.

Fully-automatic change-overHandling parts change-over at the filler and the capper can be performed up to a defined output without any manual interference.

Gentle preform treatmentThe sterilisation of the preforms hardly leaves any residues: This is because the surface enlarges by many times and the residues of the sterilisation medium are diluted accordingly.

Pinpoint productionFilling to the last drop: The system uses the remaining product quantity in order to calculate exactly how many more PET containers and caps are still to be sterilised.

Proof of safetyThe concept of the Contipure AseptBloc has FDA certification and is already in practical use multiple times.

Microbiological safetyThe system does not consume any water during operation. Therefore, there is no living space at all for microbiological organisms.

High availabilityThe entire block is in production for 168 hours non-stop. Depending on the product, it is cleaned and sterilised after 90 minutes or two and a half hours and can be used again. Intermediate cleaning after manual interventions also only takes 30 minutes.