- Home

- Companies

- Exelliq Austria GmbH

- Products

- Exelliq - Model iQ STACK - Automated ...

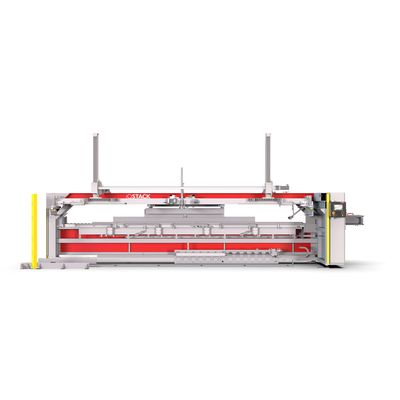

Exelliq - Model iQ STACK -Automated Stacking System

The iQ STACK Automated Stacking System by Exelliq represents an advanced solution designed for seamless integration into existing extrusion lines, facilitating a move towards fully automated production processes. This system enables the precise automatic handling of profile bars post-cut, systematically placing them into profile racks according to a predefined stacking pattern. The technology addresses labor shortages by minimizing the need for manual intervention at the extrusion line`s conclusion and ensures a smooth workflow from production to warehouse. Designed with innovation at its core, iQ STACK increases efficiency by streamlining operations and enhancing the value added throughout the extrusion process. As part of Exelliq`s comprehensive product suite, this system exemplifies their commitment to digitalization, automation, and continuous operational improvement.

Stack it the Exelliq way

The automated and ultramodern stacking system integrates seamlessly into existing extrusion lines and paves the way towards fully automated production process. This allows the profile bars to be automatically picked up after they have been cut to length and placed in the profile rack according to a desired stacking pattern. This innovative solution offers a number of advantages - from the independence from scarce personnel at the end of the line to the smooth transition from production directly into the warehouse. The focus is always on increasing added value.

- The profile length is set by manually positioning the gripper units and ranges from 4,500 to 6,500 mm. Optionally, an automatic length adjustment can be implemented and stored in the recipe, which allows a minimum profile length of 3,100 mm.

- The variable positioning of the gripper unit on both the inlet and outlet side makes it possible to place the profiles in a freely selectable position in the rack.

- The transport rack is fed in, centered and pushed out automatically.

- A non-visible infrared light grid not only supplies the necessary safety by permanently monitoring both the operating and outlet side, but also offers the best possible accessibility.

- The machine control is embedded in Exelliq's proven DIGI.CONTROL, which seamlessly integrates the iQ STACK into the connected extrusion line.

- Automatic insertion of separating strips (made of plastic or cardboard, length 630 - 700 mm, width 120 - 200 mm)

- Weighing of each profile bar

- Length measurement of each profile bar

- Optical quality control using a camera (gasket applied, film in the correct position, inner walls correspond to a reference image, ...)

- Scrap is automatically pushed to the non-operator side.

- Ergonomic control panel on height-adjustable arm

- Remote maintenance via Webcam

- Service contract