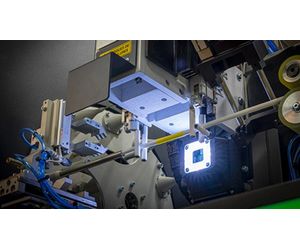

Komax Optima - Automated Wire Cutting and Identification System

The Optima series automates processes such as wire cutting, laser marking, sleeving, shrinking and labeling with precision, enhancing productivity and quality in aerospace and industrial sectors. The Optima is a versatile wire cutting and identification system that caters to both high volume and serial production, as well as high-mix low volume productions, providing a scalable solution to meet market demands. With fully controlled processes, the Optima promises high quality, eliminating the need for manual operations like labeling and sleeving, which are now fully repetitive and completely operator independent. The Optima can also integrate a laser wire marking module that provides a safe, permanent, high contrast identification on all cables guaranteed “UV-markable”, such as single or multi-wire twisted and jacketed cables.

Modular systems for diverse manufacturing needs

The Optima line has been divided into essential functions that can be added over time, allowing the machine to align with technical needs and investment capacities.

Usually demanding manual operations, such as labelling or sleeving, are now fully repetitive and totally operator-independent, not only in execution but also in control.

Unlike hot stamping, the Optima UV laser wire/cable marking process causes a reaction within the wire insulation which results in a safe, permanent and unalterable mark.

Based on diverse needs or industries, multiple tasks are required across the value chain. Flexibility is crucial for an automated solution that suits a wide range of needs.

The new HMI, a touch screen on an adjustable arm, a sliding door for full access, wire feeding assistance, and LED indicators are all user-friendly features for enhanced usability.

Metric

Optima

- Wire outer diameter min.: 0.8 mm

- Wire outer diameter max.: 8 mm

- Electrical connection: 1 x 200 – 240 V 50/60Hz; 1.2 kVA

- Compressed-air connection: 6 bar

- Humidity, non-condensing: < 80 %

- Ambient temperature: 15 - 35 °C

- Compulsory smoke extraction: The machines in the Optima range are equipped with a smoke extraction system.

- Cooling unit: The laser head is cooled by means of an integrated autonomous air-cooling unit.

- Wire lengths depending on: cable OD

- Wire type: Single-core, jacketed, unshielded multi-core, shielded multi-core

- Proceeded sleeves: Sleeves in rolls Length : 50 mm or 2 × 25 mm (precut sleeve) / 1.97 in or 2 × 0.98 in Size : 3.2mm (1/8 in), 4.8mm (13/64 in), 6.4mm (15/64 in), 9.5mm (23/64 in), 12,7mm (1/2 in)

- Sleeves printer: Up to 3 allowing 3 different types of sleeve to be processed (color and/or size)

- Sleeves by cable: Depending on the WSI configuration: 0 to 2 (for 50 mm) 0 to 4 (for 2 × 25 mm) 0 to 11 (for 50 mm)

- Extremity labels: Thermal printing, size : 40 mm × 46 mm (1.57 to 1.81 in) Information printed tailored to customer needs

- Noise level: < 75 dB

- Laser: YAG

- Printer type: Vector marking

- Laser security: Class I laser compliant with European (CE) and American standards: suitable for work in covered workshops

Imperial

- Wire outer diameter min.: AWG26

- Wire outer diameter max.: AWG6

- Electrical connection: 1 x 200 – 240 V 50/60Hz; 1.2 kVA

- Compressed-air connection: 90 psi

- Ambient temperature: 59 - 95 °F

- Humidity, non-condensing: < 80 %

- Compulsory smoke extraction: The machines in the Optima range are equipped with a smoke extraction system.

- Cooling unit: The laser head is cooled by means of an integrated autonomous air-cooling unit.

- Wire lengths depending on: cable OD

- Wire type: Single-core, jacketed, unshielded multi-core, shielded multi-core

- Proceeded sleeves: Sleeves in rolls Length : 50 mm or 2 × 25 mm (precut sleeve) / 1.97 in or 2 × 0.98 in Size : 3.2mm (1/8 in), 4.8mm (13/64 in), 6.4mm (15/64 in), 9.5mm (23/64 in), 12,7mm (1/2 in)

- Sleeves printer: Up to 3 allowing 3 different types of sleeve to be processed (color and/or size)

- Sleeves by cable: Depending on the WSI configuration: 0 to 2 (for 50 mm) 0 to 4 (for 2 × 25 mm) 0 to 11 (for 50 mm)

- Extremity labels: Thermal printing, size : 40 mm × 46 mm (1.57 to 1.81 in) Information printed tailored to customer needs

- Noise level: < 75 dB

- Laser: YAG

- Printer type: Vector marking

- Laser security: Class I laser compliant with European (CE) and American standards: suitable for work in covered workshops