Benenv - Jiangsu Benenv Environmental Protection Co., Ltd

- Home

- Companies

- Benenv - Jiangsu Benenv Environmental ...

- Products

- Benenv - Model HTJY - Automatic ...

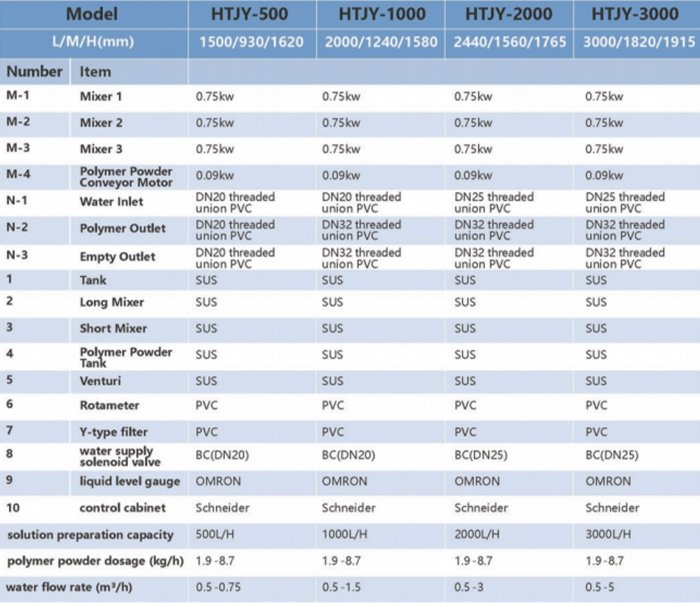

Benenv - Model HTJY -Automatic Chemical Dosing Machine

Automatic Chemical Dosing System is a auxiliary auto-equipment, which can prepare and throw polymer solution continually. It can complete the chemical combination and mixing of the polymer continually and efficiently in order to obtain homogeneous and activated solutions. The equipment can be widely used in municipal wastewater treatment, sludge dewatering treatment and other technical treatment.ts.

Most popular related searches

dissolved air flotation

solid-liquid separator

solid-liquid separation

water suspended solids

automatic chemical dosing system

wastewater sludge dewatering

chemical dosing

automatic dosing system

liquid separation

wastewater treatment

Appearance video

Fine workmanship, beautiful products, whole body stainless steel, frosting process, pay attention to details, only do boutique.

Reducer

Use Nissei or Nord brand reducers, industrial quality from Japan and Germany.

Mud inlet

The round-hole screen is used to prevent large particles and garbage from entering the dehydration body, reducing machine wear and improving machine service life.

7-shaped blade

The mixing is more complete and the flocculation effect is better.

Industry standard wiring

The mixing is more complete and the flocculation effect is better.

- Fully automatic operation could save labor costs . powder dosage is accurate and adjustable , it can ensure treatment effect and avoid waste .

- Stainless steel structure and imported components features reliable quality and good corrosion resistance .

- It is easy in maintaining and nice in appearance .

- It is easy in maintaining and nice in appearance .

- We provide powerful technology support to customize products as request .

The aim of dissolved air flotation is to separate the fine suspended solids in water, algae and micro-floc. And dissolved air flotation can be used in the following industries:

- High concentration organic wastewater treatment: paper, printing and dyeing, textile, leather, pharmaceutical, fermentation wastewater and so on.

- Biochemical effluent liquid separation: the anaerobic effluent solid-liquid separation, aerobic (activated sludge process, contact oxidation, filter) biochemical water solid-liquid separation, the secondary settling tank Effluent treatment and so on.

- Farm and slaughter house wastewater treatment: cattle, pigs, chickens farm, slaughter house wastewater.

- Manufacturing waste: electroplating, painting, etc.

- Purification: river, landscape, recycle water and so on.

- Separate or recycle waste oil or grease in : oil exploration and refining, biodiesel, machining , food production and catering and so on.

- Core Technology of dissolved air flotation for water clarification

- Micro-bubble generation technology

- Forth circulation and flocculation technology