Benenv - Jiangsu Benenv Environmental Protection Co., Ltd products

Stacked Snail Sludge Dewatering Machine

The snail sludge dewatering machine belongs to the screw press dewatering machine, which can reduce the sedimentation tank and the sludge concentration tank and save the construction cost of the sewage station. The snail sludge dewatering machine uses the automatic update filter cake filtration technology instead of the traditional filter screen filtration. The self-renewing filter cake filtration technology ensures the continuous and stable mud-water separation effect of the dehydrator, and the strong squeezing force generated by the screw diameter and pitch variation. And a small gap between the swimming ring and the fixed ring to achieve extrusion and dewatering of the sludge, is a new type of solid-liquid separation equipment.

Benenv - Screw Press Sludge Dewatering

The Multi-Disk Screw press (MDS) is a solid-liquid separator, which can realize the dewatering effect. The sludge is thickened and dewatered progressively along with the inner screw conical shape, the movement of the free rings, and ending by the rotary plate. The special tungsten carbide coating of the inner screw and its slow rotation eliminates the friction effect and assure a long life span of the parts. The filtrate is drained from the gaps between the rings, which differs from the thickening and the dewatering zones. The sludge cake is discharged at the end plate, achieving a minimum solid content of 20%. The advanced design of the MDS make it a self cleaning unit due to the friction free movement between the rings, applicable for a wide range of sludge concentration (2000 mg/L – 50000 mg/L), and it’s most suitable for oily sludgeElliptical Sludge Dewatering Machine

Environmentally friendly, vibration-free, noise-free solid-liquid separation device using the unique self-cleaning filter principle.

Benenv - Multi-Disk Screw Press

Multi-Disk Screw Press is a new solid-liquid separation equipment. The pitch of the screw and the gaps between the rings decrease, increasing its internal pressure, thus dehydration is achieved. It can be widely used in municipal sludge, food, beverage, slaughtering breeding, printing and dyeing, oil chemical industry, paper making, leather, pharmaceutical and other industries of sludge dewatering. The unique dewatering principle makes the equipment suitable for high and low concentration sludge (from 2000mg / L), creating a precedent for direct dehydration of low concentration sludge. The innovative structure design makes the equipment suitable for all kinds of sludge with high and low viscosity, especially oily sludge, which can be called a dewatering tool for oily sludge!

Mobile Sludge Dewatering System

The mobile sludge dewatering system is a new sludge treatment product designed for some special occasions such as complex environment, unstable sludge volume and temporary conditions for the existing equipment in the sludge treatment market. This product is aimed at the existing dewatering equipment on the market with high energy consumption, high input cost, large volume, difficult to move, low degree of automation, complicated operation, dirty working environment, etc. Based on the patented products developed in conjunction with the advanced technology of the company`s sludge treatment equipment. The sludge cake treated by the sludge dewatering machine has a low moisture content, and does not require the addition of an inorganic agent such as lime, thereby completely avoiding secondary pollution.

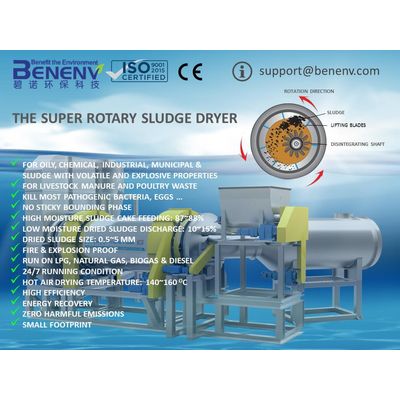

Super Sludge Dryer

The Super Sludge Dryer is a special equipment for sludge reduction. The sludge is dried by direct contact with hot air. The high-speed rotating crushing shaft is built in, which completely solves the problem of sludge adhesive phase. The sludge with different water content will be directly reduced to 20% , and the reduction amount will be 80% . The quality of the sludge after drying is uniform and the particle size is small ( 1~5mm ). After treatment, the sludge can be used as fuel. The equipment incorporates the expertise of experts in the fields of incineration, drying and carbonization in Japan and professors from well-known universities in China.

Benenv - Screw Press Sludge Dewatering Machine

Multi-Disk Screw Press( Hereinafter referred as MDS ) belongs to the screw press, it`s clog-free and can reduce the sedimentation tank and sludge thickening tank, saving the cost of sewage plant construction. MDS using screw and the moving rings to clean itself as clog-free structure, and controlled by the PLC automatically, it`s a new technology that can replace the traditional filter press like belt press and frame press, the screw speed is very low, so it cost low power and water consumption in contrast to the centrifuge, it is a cutting edge sludge dewatering machine.

Benenv - Benenv Sludge dryer

The super sludge dryer is equipped with a unique crushing and stirring device in the drying cylinder, and the rotatable cylinder itself also has the function of crushing and stirring The pulverizing and stirring device can pulverize and disperse materials such as sticky and lumps, so as to increase the hot air contact efficiency, and the cylinder body can ensure that the dry product with uniform quality (particle size is 0.5-5 mm) can be obtained in a short time. It can be used for dewatered sludge, pharmaceutical sludge, chemical sludge, heavy metal sludge and other sludge with high viscosity. Direct contact dryers cannot be used for oily sludge with oil content >2% and sludge with volatile and explosive properties. Indirect super sludge dryers can be used for such sludge.Benenv - Wave separator Sludge thickening and dewatering

The Wave Separator is a solid-liquid separation equipment, with thickening and dewatering functions. It is a self-cleaning machine, due to the continuous synchronized rotation of special oval discs between the slits. The Wave Separator is a patent product, making it a universal machine used in various applications & industries. Its design allow it to be a simple thickener for waste and wastewater from 0.5% to 10%, improving the post dewatering phase. The slits gap is adjusted according to the treatment purpose. When it’s used as a dewatering machine, the pressure plate assure a discharged cake with a minimum solid content of 25%.Intelligent High-Temperature Aerobic Fermentation System

The intelligent high-temperature aerobic fermentation system is the latest from Japan. It is mainly used for high-temperature aerobic fermentation of livestock and poultry manure, meal waste, domestic sludge and other wastes, and uses microorganisms to decompose solid organic matter in waste. Efficient equipment that achieves the goal of harmlessness, stabilization, reduction, and resource utilization. The degree of automation is high, the floor space is small, and the treated product can be used as organic fertilizer to realize the resource utilization of waste.