- Home

- Companies

- Sanborn Technologies

- Products

- Sanborn - Automatic Self-cleaning ...

Sanborn - Automatic Self-cleaning Coolant Recycling System

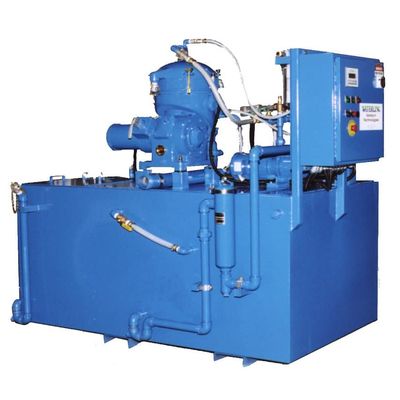

The Sanborn “CP” Systems are the most efficient and effective coolant recycling systems in the industry. The heart of the CP system is the Mitsubishi self-cleaning high-speed disc centrifuge that provides highly effective coolant purification by removing fine solids and tramp oil down to negligible levels for pristine coolant recycling.

All CP Systems include Sanborn`s proprietary mixing system in the dirty coolant tank that maintains a homogeneous feed to the centrifuge for effective coolant purification. This process will completely mix the tramp oil and solids for effective removal in the three-phase high speed disc centrifuge for superior separation performance to maximize coolant recycling and at the same time minimizing spent coolant waste.

Purified coolant from the high-speed disc centrifuge is discharged into a clean coolant storage tank, while separated tramp oil is discharged into a waste oil drum for further reclamation by a licensed waste oil recycler. Periodically, the clarified solids are automatically self-ejected from the centrifuge and discharged to a solids cart or a customer designated waste container.

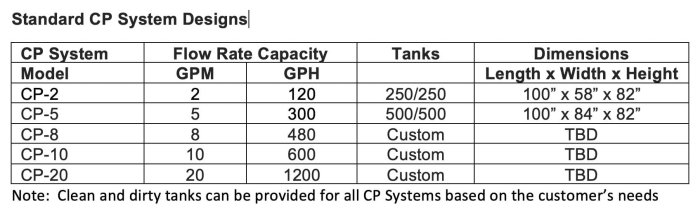

Sanborn CP Coolant Recycling Systems can be installed as a free-standing fully automated system equipped with process tanks for batch operations or used for continuous on-line processing of centralized coolant sumps. CP Coolant Recycling Systems have processing capacity ranges from 1 to 20 GPM.

Superior Coolant Purification to Pristine Levels

- Removes solids down to less than 5 microns (≤5 µm)

- Separates tramp fluids down to 1/4 of 1% (0.0025%)

- Reduced coolant waste by minimizing the volume of coolant removed with the tramp oil and rag layer

Simple and Efficient Operation

- Single-pass processing returns completely purified fluid

- System delivered pre-piped, pre-wired and pre-tested

- Dramatic Direct Cost Savings

- Reduce fluid waste disposal costs up to 99%

- Reduce new fluid purchases by up to 95%

- Improved Quality and Productivity

- Cut machine down time for sump cleanouts

- Improve tool efficiency and product quality

Water-based Coolants

- Water Soluble

- Semi-synthetic

- Pure Synthetic

Oils – With the selection of the proper disc stack for oil, the CP Systems can also be configured for oil purification applications as well.

- Cutting Oils

- Hydraulic Oil

- Turbine Oil