Komax Omega - Model 840 -Automatically Wire Assembly Machine

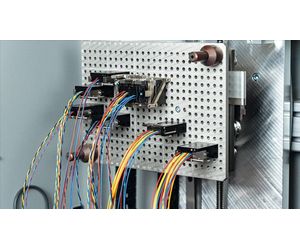

The Omega 840 / 850 wire assembly machine automatically produces wire harnesses with individual wires with cross-sections of 0.13 –2.5 mm² as well as twisted wires. Unlike its predecessor models, the Omega 8xx series can assemble wire harnesses with both single wires and twisted wires fully automatically. Depending on the model, six (Omega 840) or ten (Omega 850) modules can be fitted for specific applications. The insertion process is monitored by an integrated force sensor. The individual wires are produced inline on the machine and the twisted wires are fed by means of a wire cartridge. The parameters of the corresponding components can be programmed via the user-friendly TopWin interface. During processing, the process parameters are saved for seamless quality control.

Precise wiring harness assembly with twisted wires

The Omega 8xx series produces pallets of fully assembled single and twisted wire harnesses fully automatically and extremely efficiently.

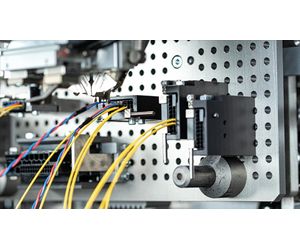

Two insertion heads insert the twisted wires into the housing correctly, fully automatically, precisely and without user intervention.

The twisted wires produced on a Sigma, for example, are fed by means of a cassette and automatically removed by the double rotary gripper.

Twisted wires are measured with the TMPS optical measuring system and the angle is aligned to ensure fully automatic, correct insertion.

Omega 840

Metric

- Cycle time per loading (twisted pair): 2.2 – 4.4 sec

- Wire outer diameter (twisted pair) max.: 1.6 mm

- Wire cross section (twisted pair) max.: 0.75 mm²

- Shortest wire length for one-sided processing: 0.13 mm²

- Shortest wire length for two-sided processing: 240 mm

- Shortest wire length, double-sided jumper connection: 300 mm

- Shortest wire length, double-sided jumper connection: 300 mm

- Shortest wire length, double-sided jumper connection max.: 540 mm

- Shortest wire length, complex loading min.: 300 mm

- Shortest wire length, complex loading max.: 760 mm

- Wire length (standard tray) max.: 3000 mm

- Strip length side 2 max.: 25 mm

- Strip length side 1 max.: 25 mm

- Wire outer diameter max.: 4 mm

- Wire cross section min.: 0.13 mm²

- Wire cross section max.: 2.5 mm²

- Wire draw-in speed max.: 10 m/s

- Wire acceleration: 50 m/s²

- Cycle time per loading: 1.8 – 2.6 sec

- Length accuracy: ± 1 mm oder < 0.2% (depending on the wire length)

- Noise level (without crimp modules) max.: 75 dB

- Electrical connection: 3 × 208 - 480 V, 50/60 Hz, 4kVA (base machine)

- Compressed-air connection: 5-8 bar

- Network connection: Ethernet

- Exhaust connection: Upon request

- Recommended operating pressure ±0.5bar/7.25psi: 6 bar

- Compressed-air quality in accordance with DIN/ISO 8573-1: Compressed air, dry, filtered (10 μm), oil-free

- Minimum permissible cross section of connection lines: DN 15

- Recommended size of compressed-air storage per machine: 50 l

- Weight (approx.): 2280 kg

- Weight of block loader (approx.): 1020 kg

- Floor load capacity: 500 kg/m²

- Maximum permissible operating pressure: 6.5 bar

- Length: 6230 mm

- Width: 2200 mm

- Height (with safety cover closed): 2060 mm

- Height (with safety cover open): 2870 mm

- Minimum clearance around equipment for maintenance work: 1500 mm

- Floor conditions: Flat, stable, clean and vibration-free support surfaces. Support surface for machine load points made from a continuous base plate of concrete. No expansion joints between machine load points. Support surface non-slip. No plastic or asphalt coatings

- Processing outside the specifications: Processing outside the specifications upon request. In case of doubt, we will be happy to provide processing samples for your wires.

Imperial

- Cycle time per loading (twisted pair): 2.2 – 4.4 sec

- Wire outer diameter (twisted pair) max.: 0.063 in

- Shortest wire length for one-sided processing: AWG26

- Shortest wire length for two-sided processing: 9.45 in

- Shortest wire length, double-sided jumper connection: 11.81 in

- Shortest wire length, double-sided jumper connection: 11.81 in

- Shortest wire length, double-sided jumper connection max.: 21.26 in

- Shortest wire length, complex loading min.: 11.81 in

- Shortest wire length, complex loading max.: 30 in

- Wire length (standard tray) max.: 118 in

- Strip length side 2 max.: 0.98 in

- Strip length side 1 max.: 0.98 in

- Wire outer diameter max.: 0.16 in

- Wire cross section min.: AWG26

- Wire cross section max.: AWG14

- Wire draw-in speed max.: 33 ft/s

- Wire acceleration: 165 ft/s²

- Cycle time per loading: 1.8 – 2.6 sec

- Length accuracy: ± 0.039 in or < 0.2% (depending on cable length)

- Noise level (without crimp modules) max.: 75 dB

- Electrical connection: 3 × 208 - 480 V, 50/60 Hz, 4kVA (base machine)

- Compressed-air connection: 73-116 psi

- Network connection: Ethernet

- Exhaust connection: Upon request

- Recommended operating pressure ±0.5bar/7.25psi: 87 psi

- Compressed-air quality in accordance with DIN/ISO 8573-1: Compressed air, dry, filtered (10 μm), oil-free

- Recommended size of compressed-air storage per machine: 50 l

- Weight (approx.): 5027 lb

- Weight of block loader (approx.): 2248 lb

- Floor load capacity: 500 kg/m²

- Maximum permissible operating pressure: 6.5 bar

- Length: 245.3 in

- Width: 86.6 in

- Height (with safety cover closed): 81.1 in

- Height (with safety cover open): 113 in

- Minimum clearance around equipment for maintenance work: 59 in

- Floor conditions: Flat, stable, clean and vibration-free support surfaces. Support surface for machine load points made from a continuous base plate of concrete. No expansion joints between machine load points. Support surface non-slip. No plastic or asphalt coatings

- Processing outside the specifications: Processing outside the specifications upon request. In case of doubt, we will be happy to provide processing samples for your wires.