- Home

- Companies

- Potential Engineering

- Products

- Potential - Ballast Decanter

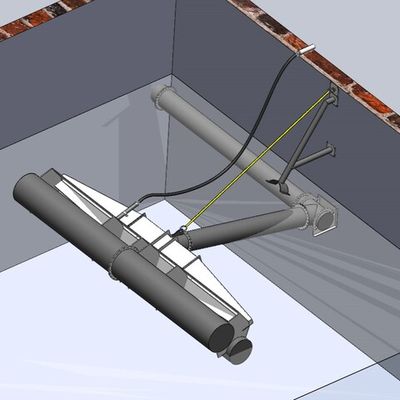

Potential - Ballast Decanter

Decanters are deployed in sequencing batch reactor (SBR)/ Cyclic wastewater processes to separate the sludge from clear effluent. We have developed a Ballast decanter which is a scum/solids excluding floating type decanter. The decanter is air powered and can be driven by the plant`s aeration system thereby eliminating the need for any complex equipment. Vertical movement of the decanter is established by injecting or releasing pressurized air. The emergency level is fixed at a maximum position to eliminate possible overflow. The lower position is arrested by a stopper provided at the bottom of the tank. The entire system can be moved to ground level for maintenance with help of the winch.

We manufacture Ballast decanter which is a scum/solid excluding floating type decanter for use in SBR/ Cyclic wastewater processes. The decanter is air powered and is driven by the plant’s aeration system. The decanter has two positions, cut-off and work. The decanter is moved in a vertical direction by injecting or releasing pressurized air into the body of the decanter.

- Decanter size: 300 mm, 400 mm, 500 mm & 600 mm

- Decanter Capacity at 3 m height (m3/h): 850, 1575, 2450 & 2625

- Three-way valve size: 40 mm (for 300 & 400 mm decanter size) and 50 mm (for 500 & 600 mm decanter size)

- Compressed Air: 800 LPM (for 300 mm & 400 decanter size) and 2500 LPM (for 500 mm & 600 mm decanter size)

- Compressed Air Pressure: 0.05 Kg/cm2 for all decanter sizes

- Designed to handle large flow

- Manual or automatic operation

- Easy to install

- Low maintenance

- Safe operation in hazardous areas

- Spares are easily available

- SBR Plants

- Oil & Gas

- Water & wastewater

- Power

- Steel

- Municipal

- Mining

- Dairy

- Sugar

- Pharmaceuticals

- Food & beverages

- Chemicals

- Miscellaneous (Wood, textiles, glass, paper, etc)