Biomass Engineering & Equipment (BE&E)

- Home

- Companies

- Biomass Engineering & Equipment (BE&E)

- Products

- BE&E Smart - Twin Chain Drag Conveyors

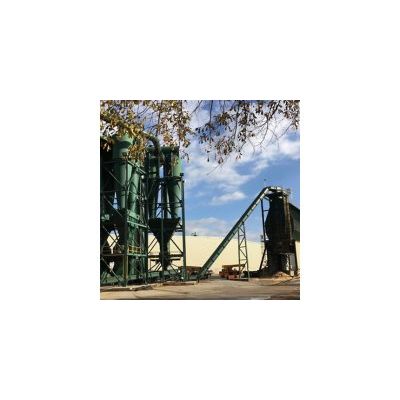

BE&E Smart - Twin Chain Drag Conveyors

Twin chain drag conveyors from BE&E are highly refined, modular drag chain conveyors for material handling. These conveyors allow for wide customization from a catalog of shapes, sizes, and material options. We offer both top-drag and bottom-drag chain conveyors to best suit your needs. Future changes to the conveyors are as easy as bolting new sections in place. All sizes are available with straight sections, inside curves, outside curves, manual or automatic tensioning, direct drives in constant or variable speeds, feeding bins, manual or automatic conveyor gates, and more.

Most popular related searches

chain conveyor belt

drag conveyor

chain conveyor

wood chip

conveyor monitoring

wood shavings

materials handling conveyor

wood sawdust

pneumatic conveyor

- One half the power requirements of other systems

- Space-saving inclines — 75° angle, no problem

- Clawed paddles to limit stresses on the paddle system

- Modular, bolt-together construction for easy assembly and future changes

- Variety of sizes to match your volume requirements

- Dust tight – fully enclosed, no leaks and no exposure to moving parts

- Ease of maintenance – change curve wear strips in minutes from outside, see for yourself!

- Reliable – simple maintenance will keep our conveyor going for years

- Quiet – no metal-to-metal contact except for the chain on the sprocket

- Safe – direct shaft-mounted inverter duty drives – no pulleys, belts, guards, or pinch points

- Configurations and options – top or bottom drag with optional features: AR floor liners, electric or pneumatic gates, and conveyor monitors

- Materials – wood chips, sawdust, wood shavings, bark, mulch, grasses, stover, distillers grain – virtually any bulk material