- Home

- Companies

- Benenv - Jiangsu Benenv Environmental ...

- Products

- Benenv - Model BRD - Benenv Sludge ...

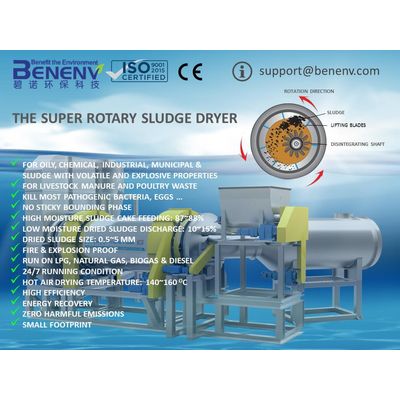

Benenv - Model BRD -Benenv Sludge dryer

The super sludge dryer is equipped with a unique crushing and stirring device in the drying cylinder, and the rotatable cylinder itself also has the function of crushing and stirring The pulverizing and stirring device can pulverize and disperse materials such as sticky and lumps, so as to increase the hot air contact efficiency, and the cylinder body can ensure that the dry product with uniform quality (particle size is 0.5-5 mm) can be obtained in a short time. It can be used for dewatered sludge, pharmaceutical sludge, chemical sludge, heavy metal sludge and other sludge with high viscosity. Direct contact dryers cannot be used for oily sludge with oil content >2% and sludge with volatile and explosive properties. Indirect super sludge dryers can be used for such sludge.

Advantages:

1: Direct contact drying, K is the largest, high efficiency (80~90%),

energy consumption and the amount of additional water are almost

in a straight line.

2:Discharge moisture content is adjustable, 5%~40%.

3:No sticky phase, residence time 10 minutes ( high speed

crushing, crush the sludge into 0 5 5 mm particles size, directly dry it with hot air

at about 150150°C, and recycle the waste heat of the exhaust gasgas)

4:It has been used in Japan since more than 30 years and has more than 2,000

cases. It is mature and reliable

5:Small footprint

6:No odour (slight negative pressure + mature exhaust gas treatment

7:No dust Exhaust gas temperature > 100 ℃℃, cyclone dust removal and cloth

bags can be added . (no Moisture in the dust collection

8:Safe (30 years in Japan, thousands of cases, no accidents ; negative pressure

in the system + high humidity of water vapor + hypoxia + control + mechanical

pressure relief) no risk of explosion

9:No water vapor corrosion.

10:Durable, the service life can reach more than 20 years.