- Home

- Companies

- Benenv - Jiangsu Benenv Environmental ...

- Products

- Benenv - Model OA1 - Rotary Drum Screen

Benenv - Model OA1 -Rotary Drum Screen

Reliable and effective mechanical solid-liquid separation.

- Built-in slag crushing

- Configure grid slag washing

- Compact design

Appearance video

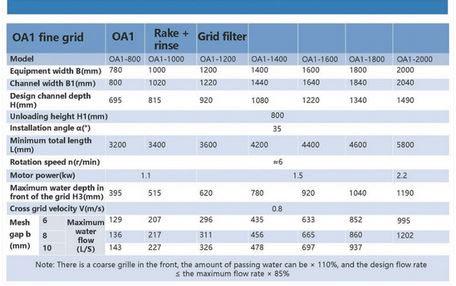

The equipment is installed at an angle of 35 degrees in a channel or a tank. Sewage flows into the basket from the opening on the end face of the grille, and scum, sediment and suspended matter are intercepted accordingly. The grid residue on the grid basket produces a carpet effect, further improving the filtration and separation efficiency.

When the water level before and after the grid reaches a predetermined water level difference, the slag scraping arm fixed on the central axis starts to rotate, the slag scraping teeth penetrate into the grid gap, thoroughly clean the grid basket, remove the grid slag and raise it to the highest vertical position Drop it into a central hopper with a transfer screw. In order to completely clean the grid slag on the slag scraper, the slag scraper reaches the highest position and returns to about 15 °. The slag scraper is cleaned on the way by a slag card.

The conveying screw rotates to discharge the grid slag through the rising pipe. After the grid slag is dewatered and squeezed, it acts as a container and subsequent transport devices. The entire process is clean and free of odours.

Low head loss-high separation efficiency

The shape of the grid basket and the installationangle of 35 ° make the filtering area much larger than the vertical or large-angle grid, so the head loss is low, the separation efficiency is high, and the processing capacity is large.

All stainless steel

The machine is made of stainless steel and treated with acid passivation to prevent corrosion and reduce maintenance work.

Reliable mandatory self-cleaning

Through the rotary slag cleaning, the entire filtering area will be thoroughly cleaned, and even under high pollution conditions, this mandatory cleaning can ensure an effective filtering area. In addition, it will also ensure that the grid slag will continue to be intercepted in the grid basket (before the filtering area), that is, the grid slag will not fall through the grid gap into the effluent stream during the cleaning process.

Multifunctional in one system

The OA1 series grille has grid slag filtration, transfer, flushing and dewatering functions in a single compact unit. Additional closures ensure that no odour escapes during operation of the entire unit.

Outdoor installation

Outdoor installation of OA1 series grille can be equipped with anti-freeze protection device, and additional isolation measures can be added if necessary.

Refurbishment

The design of the OA1 series grille allows for subsequent improvements and configuration updates if necessary. Both the heating device and the integrated grid cleaning system can be configured later.

Low maintenance workload

No lubrication is required, just regular inspection and inspection.