- Home

- Companies

- Coulson Ice Blast

- Products

- Better alternative to Dry Ice Blasting

Better alternative to Dry Ice Blasting

Ice Blasting is an industrial cleaning technology, like sandblasting or pressure washing. However, instead of using sand or liquid water, crushed ice cubes are propelled at high speed towards the surface to be cleaned. Renders obsolete dry ice blasting technology, since water ice is significantly cheaper and does not pose a risk of asphyxiation to the operator, is more aggressive at cleaning and makes capture and containment of blasted off particulates much easier. Unlike sandblasting, the ice just melts and evaporates away, leaving much less resultant waste to clean up. Ice blasting uses 1/10th of the water compared to pressure washing, meaning that there is much less dampness left over, while also being more aggressive, since a solid particle can impart more impact force than a liquid. In general, with ice blasting, there are much less airborne contaminants during blasting and waste containment is much easier than with competing technologies. https://www.coulsoniceblast.com/

By using conventional ice as a blast media, Coulson’s patented Ice Blast technology has a low operating cost. The ice can be in nearly any form convenient for the user. It can be in the form of larger ice blocks, made practically for free in a freezer, or in the form of ice cubes, made using standard ice cube makers like the ones found in restaurants or hotels. Coulson Ice Blast is also partnered with an international network of ice cube suppliers, from whom ice can be bought at $0.19 a pound and delivered right to where you need it.

In comparison, dry ice costs $0.50 a pound, with much of it sublimating away during transport and lasting only a few days if is not used immediately.

Ice blasting makes containment and disposal easier and thus more environmentally friendly, uses 1/10th of the water compared to pressure washing and does not take much energy to create. Unlike dry ice or abrasive blasting media, it can also be made on the job site, reducing the environmental impact of transport.

Much of the ice melts on impact and becomes a mist around the work area, making blasted off particulates damp and heavy, dragging them to the ground and leaving low levels of airborne contaminants. This means that there is less risk of airborne flakes of hazardous material blowing into the surrounding environment. Due to minimal water usage and evaporation from impact energy, the only waste left behind is a neat, slushy pile of easily captured contaminant in a tarp placed beneath the blast zone.

All other competing industrial cleaning technologies have an inherent problem with containment and disposal of hazardous waste. With pressure washing, due to the high flowrate of water, contaminants wash away into the surrounding environment and into drinking supplies. Sandblasting results in airborne hazardous waste and contaminated sand that must be cleaned up and disposed of in landfills.

Compared to dry ice, ice is much less energy intensive to make. The CO2 used to make dry ice is either generated for that purpose, adding to the problem of global warming, or it is purchased from industrial facilities that generate CO2 as a byproduct during the production of something else. Since these industrial facilities are making money by selling CO2 for dry ice production, there is less insentive for them to switch over to more efficient and environmentally friendly processes. Not to mention the environmental impact from transporting CO2 to the dry ice production facility, generating the dry ice and then transporting it to the end-user, all of which may be remote from one another, whereas ice can be made anywhere, including right at the job site.

In the industrial cleaning sector, airborne contaminants are a prime concern when performing any cleaning task. Protective clothing and respiratory aid is necessary when using abrasive cleaning technology. Ice blasting is the only real dustless blasting method available on the market today, with low levels of airborne contaminants during blasting.

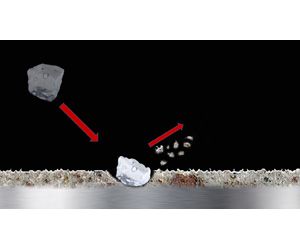

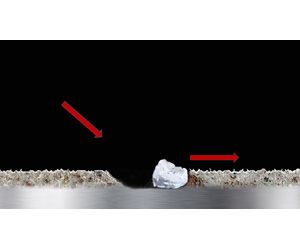

The cleaning method used in wet-ice blasting falls under three steps:

Bulk Removal: The stage where major contamination is removed. Since it is a hard solid, ice can deliver a much higher impulse force on impact than something soft like water, which tends to flow around strongly adherent contamination. This high initial impulse overcomes the bonding force between the contaminant and the surface to be cleaned, knocking it off.

Detail Cleaning: Immediately after impact, the ice slides along the surface of the part. This acts to scrub/polish the surface, removing minute quantities of the remaining contamination from the surface. By definition, scrubbing means two solids moving relative to each other under applied pressure. Water as a blast-cleaning agent therefore cannot offer this property.

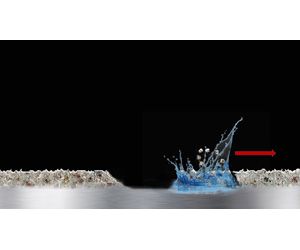

Final Rinse:

The energy of impact and scrubbing acts to melt the ice. The melt water rushed over the surface, dissolving rust causing ionic compounds like salt and washing them away. Water is called the universal solvent due to the large number of compounds it is able to dissolve. Many alternatives to ice blasting require an additional rinse on top of the blasting action.

Ice blasting uses normal ice made from water as a blast media, while dry ice blasting uses solid CO2 as a blast media.

Ice blasting and dry ice blasting are both considered non-abrasive blasting. This means that they are not hard enough to scratch and damage most surfaces. As described previously, the primary cleaning mechanism of ice is through high impact force, capable of breaking the bonds between the contaminate and the surface to be cleaned, rather than through abrasive scratching. This means that just the contaminate is removed, with low risk of damage to the surface beneath.

However, CO2 is toxic and can cause asphyxiation even at relatively low percentage levels of air. OSHA has a CO2 exposure limit of 5,000 ppm (0.5% by volume). Dry ice blast machines use up to 5 lb/min of solid CO2, which, when it sublimates, expands by a factor of 800 and completely occupies a volume of 44 cubic feet in one minute (and then multiply that volume by 200 to stay under the 0.5% exposure limit. It wouldn`t take long to asphyxiate by dry ice blasting in an enclosed space). This means that, to safely blast in an enclosed space, the operator must have a supply of breathing air. There is also a risk that passersby approaching the indoor blast zone, unaware of the dangers, could asphyxiate.

Alternatively, ice blasting is much safer to operators and passerby, since moisture in the air is no more dangerous than a rainy day. Additionally, the wetness of the process helps to reduce the amount of airborne contaminants, therby reducing breathing hazards.

Ice is more accessible, can be made onsite and is much cheaper than dry ice. It is also harder and so more aggressive for blasting compared to dry ice. Ice also has the advantage of making capture and containment easier, by making blasted off particulates damp and heavy and dragging them to the ground, leaving a neat slushy pile of easily captured contaminant on a tarp placed beneath the blast zone.

Ice is the only blast media that uses all three physical phases to advantage during blasting: its solid phase knocks off contaminants with maximum impulse, as well as scrubs the surface, its liquid phase dissolves and washes away ionic compounds, as well as helping to suppress dust, and its vapor phase evaporates, leaving behind minimal residue and dampness.