- Home

- Companies

- Monitor Technologies, LLC

- Products

- Evasser - Bin Aeration Device

Evasser - Bin Aeration Device

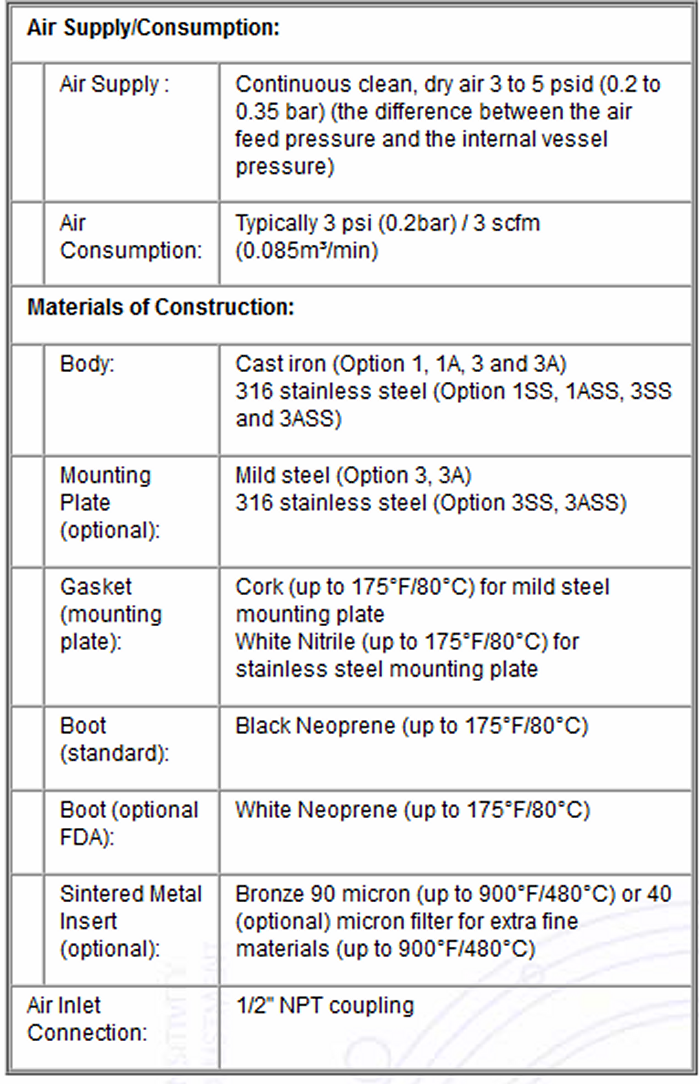

The Evasser bin aerator from Monitor Technologies is an aeration device used to promote the fluidization and flow of dry bulk powders from a storage vessel (bin, silo, hopper) without the noise and damaging vibration caused by pneumatic or electric vibrators. The Evasser aerator is small, compact and capable of aerating many types of bulk powders and granular solids in bins, hoppers and silos. The Evasser can discharge air up to 80 psi (5.5 bar) to move settled materials. Once material is flowing the Evasser can be used to maintain flowability of material with a constant 2 to 5 psi (0.14 to 0.35 bar) supply of air.

- luidizes Materials in Bins, Hoppers and Silos

- External Mounting Available

- No Damaging Vibration

Unlike other types of aerators that use cotton or canvas to diffuse the air, the Evasser is less likely to be bound or clogged due to moisture and can be more effective as it directs air flow to `sweep` the bin wall. In addition, the Evasser is not as prone to back-flow of material as the standard neoprene boot expands to let the pressurized air out and contracts when the air is shut off blocking the air outlets from material backflow.

The Evasser bin aerator is available with a convenient external mounting plate. This means that installation of the device can be done from outside of the bin making it ideal for use in replacing worn and plugged air pads. In addition, with no moving parts or filters to clean or replace the Evasser requires virtually no maintenance.

The single Evasser bin aerator operates by continuously introducing air into a mass of stored powder. When first conveyed into a storage vessel, the powder is a highly aerated mixture of air and particulate. In this state, the mixture flows quite easily. As the material settles, the particulate and air separate. The material decreases in volume and increases in density (it packs), and in turn it begins to behave like one solid mass rather than a fluid mixture of particles. The Evasser replaces the naturally lost air and increases and maintains the air-to-particulate mixture ratio, thus allowing the material to flow.

The most effective aeration of dry bulk materials is typically achieved by the use of four rows of Evassers, one row located in each quadrant of the slopping bin bottom. With aerating dry powders the Evassers will normally be spaced 18in on centers, with the lowermost units located close to the outlet where most of the bridging starts. On granular materials the location of the Evassers will vary with the material being aerated and the configuration of the bin. In all cases, please consult with the Monitor application engineers that are ready to provide you with the best recommendation for your specific material flow problem.

Typical Applications include, but are not limited to:

- Cement

- Bentonite

- Gypsum

- Soda Ash

- Lime

- Flour

- Carbon Black

- Fly Ash

- Other

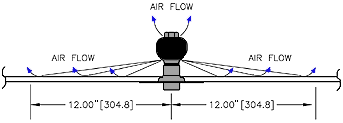

- Typical effective radius of 12 inches (305mm)

- Compact and low cost with virtually no maintenance

- Available in cast iron or 316 stainless steel

- Black Neoprene boot or optional white FDA Neoprene boot

The Evasser bin aerator is available in several configurations. The Evasser itself can be provided in either cast iron or 316 stainless steel construction. The Evasser is normally supplied with a black Neoprene boot. A FDA approved white boot is also available. For high pressure or high temperature applications where the boot is not acceptable, a sintered metal insert can be provided. In addition, each of these configurations can be provided with or without the external mounting plate.

Monitor Technologies warrants each evasser it manufactures to be free from defects in material and workmanship under normal use and service within two (2) years from the date of purchase. The purchaser must notify Monitor of any defects within the warranty period, return the product intact, and prepay transportation charges. The obligation of Monitor Technologies LLC under this warranty is limited to repair or replacement at its factory. This warranty does not apply to any product which is repaired or altered outside of Monitor Technologies` factory, or which has been subject to misuse, negligence, accident, incorrect wiring by others, or improper installation.