- Home

- Companies

- Ecologix Environmental Systems, LLC

- Products

- Bio-Clear - Biological Treatment System

Bio-Clear - Biological Treatment System

The Ecologix Bio-Clear utilizes an extended aeration principle and functions by creating an environment with sufficient oxygen levels and agitation to allow for bio-oxidation of the wastes to suitable levels for discharge. The Bio-Clear system provides a modular approach to the treatment of wastewater. It’s compact design, ease of operation, and exceptional track record deliver extraordinary results – all packaged together in a system suited for any biological treatment application.

- Pre-engineered, pre-fabricated structures

- Easily transported to customer`s site

- Quick turnaround and installation

- Simple operation/low manpower

- Effective aerobic operating principal

- User friendly - low and easy maintenance

- Meets all regulatory compliant

- Long service life, 30+ years

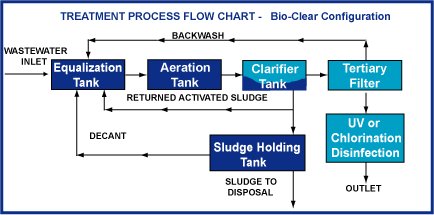

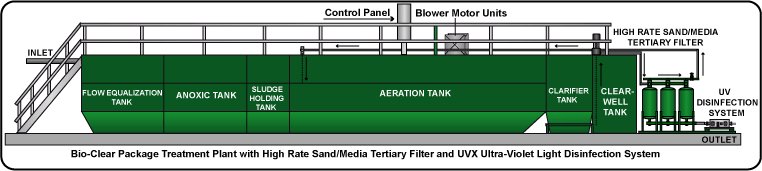

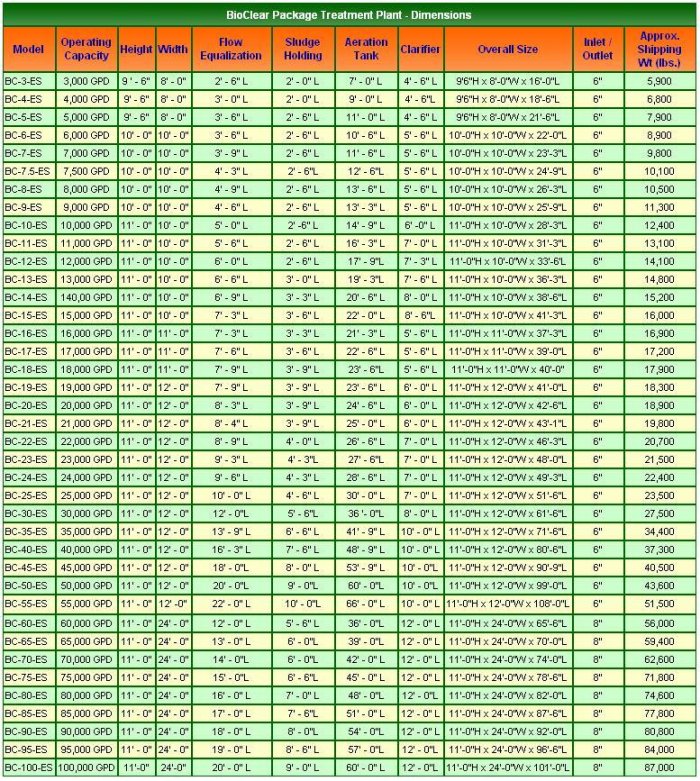

- Application specific systems

The package wastewater treatment system utilizes an extended aeration principal of operation which is a variation of the activated sludge process. This system functions by creating an environment with sufficient oxygen levels and agitation to allow for bio-oxidation of the wastes to suitable levels for discharge. The package wastewater treatment system utilizes a multi-step treatment process to achieve the desired final discharge requirements. The treatment systems consist of comminution, screening, diffused aeration, clarification, sludge recirculation, sludge digestion, disinfection, and filtration. Pre-engineered modular components such as diffused air blowers, aeration tanks, sludge holding tanks, clarifiers, and disinfection units allow for the package plants to be sized specifically for the customer`s application. They can be designed to handle a variety of influent flows and BOD loadings, as well as meet a myriad of mandated discharge parameters.

The influent wastewater enters the package plant by passing through a comminutor and bar screen for gross solids removal. This step provides for the mechanical reduction of solids prior to aeration. Once the wastewater has entered the aeration chamber, the untreated flow is mixed with an active biomass in a rolling action which takes place the length and width of the chamber in a slow forward progression. This rolling mixing action is the result of air originating from diffusers located along one side of the wall and bottom of the tank. This insures that adequate mixing is maintained in the tank. The chambers are filleted on each side and the bottom to assure and enhance the rolling motion of the water and eliminates any `dead zones` in the tank. This design feature also minimizes the accumulation of scum and froth in the aeration tank. The oxygen transfer achieved with the diffused air passing through the wastewater coupled with the rolling action provides a sufficient oxygen supply to allow microorganisms to oxidize treatable wastewater into carbon dioxide, water, and a stable sludge.

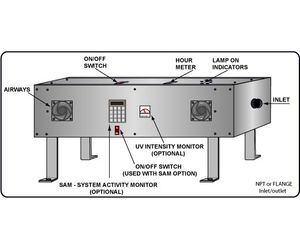

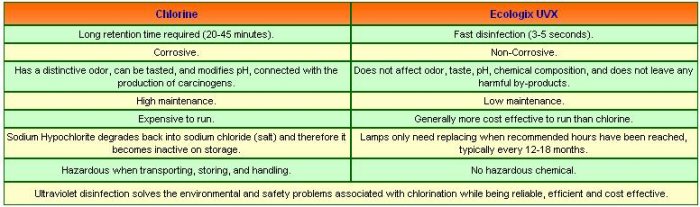

The (UVX) Ultra-Violet disinfection System is unique to the Bio-Clear Package Treatment Plant Sewage Systems. As an alternative to chlorine disinfection the UVX is compact and easy to install. With the use of an ultra-violet light disinfection system you can avoid shipping chemicals involved in chlorine contact tanks.

How it works....Just beyond the visible light spectrum there is a band of electromagnetic radiation which we commonly refer to as ultra-violet (UV) light. When ultraviolet radiation is absorbed by the cells of microorganisms, it damages the genetic material in such a way that the organisms are no longer able to grow or reproduce, thus ultimately killing them. This ability of UV radiation to disinfect water has been understood for almost a century, but technological difficulties and high energy costs prevented widespread use of UV systems for disinfection. Today, however, with growing concern about the safety aspects of handling chlorine and the possible health effects of chlorination by-products, UV disinfection is gaining in popularity. Technological advances are being made and a growing number of manufactures now produce UV disinfection systems for a variety water and wastewater applications. As operating experience with installed systems increases, UV disinfection is expected to become the practical alternative to the use of chlorination at many municipal water treatment plants.

- Stainless Steel Construction

- Minimum of 4 XUV Lamps

- 12,000 hour UV lamps

- Temperature controlled to maintain optimum UVC output of the lamps

- Utilize AFP 840 tube for effluent passage

- Double O-ring seals on AFP tube

- Swivel Union Inlet/Outlet connectors

- High Efficiency Electronic Ballasts

- Isolated ballast compartment

- Teflon coated electrical wiring

- Digital elapsed time meter

- LED lamp on indicator

- Internal UV sensor

- Pre-engineered, prefabricated structures lower cost

- Easily transported to customer`s site

- Design allows for quick turnaround for installation

- Simple operation/low manpower required

- Effective aerobic operational principal

- User friendly - low and easy maintenance

- Regulatory compliant

- Long service life

- Custom design/ Application specific systems

Typical Applications for the Bio-Clear Package Treatment Sewage System

- Land Development/housing subdivisions

- Small and medium sized cities

- Trailer Parks

- Remote mining, logging, and construction sites

- Recreational areas, parks, and marinas

- Low Flow / High Strength and High Flow / Low Strength application

- Biological treatment for industrial wastewater flows