- Home

- Companies

- Biotal Bulgaria Ltd.

- Products

- BIOTAL - Biological Wastewater ...

BIOTAL - Biological Wastewater Treatment Plants

BIOTAL Plant production capacity ranges from 1 to 1,000 m3/24-hour-period. BIOTAL Plants of a capacity from 1 to 100 m3/24-hour-period are made from shock-resistant and long-lasting polyethylene and propylene, produced in Denmark and Germany. BIOTAL Plants of a capacity from 200 to 1,000 m3/24-hour-period can be made under a standard or special design from plastics and reinforced concrete with special additives.

Waste water treatment should not involve any methods, which disrupt water structure and change water biological activity. The properties of treated waste waters must be close to those of natural water.BIOTAL technology is based on a concept different from the classic one, namely: to treat waste waters and to process treatment products until consumption products are obtained - service water and organic-mineral fertilisers. Well-treated waste waters can also partially solve the water supply problem as they can be used for service purposes, while poorly treated waste waters involve the problem of their discharge and eventually pollute the environment. The stabilised and dehydrated surplus sediments, released by the system, can be excellent organic-mineral fertiliser.

Considering the specific operation features of small treatment plant, which function under conditions of high irregularity of hydraulic and organic loads and changes in the composition and properties of arriving waste waters, BIOTAL engineering solutions were mainly directed to ensuring high quality of treated waters and stable operation with reasonable capital investments and energy consumption.

- BIOTAL Plant includes three consecutively connected SBR-reactors. Thanks to the technology design, the treated waste waters pass through a complete cycle of biological treatment in each of the three SBR reactors, while flowing through them.

- If there are no waste waters arriving to the BIOTAL Plant, it automatically switches to First (after 1 hour), Second (after 24 hours) and Third (after 168 hours) Economy Mode of Operation. This makes it possible to considerably reduce the consumption of electric power and to extend the life of the equipment.

- The Plant automatically switches into Forced Mode of Operation in the event of sudden and large inflow of waste waters in quantities exceeding design values. This is ensured by the automation, winch instantaneously switches the last SBR Reactor into a Settling Mode of Operation with subsequent pumping out of cleaned waste waters into the tertiary settling tank. Also, the last SBR Reactor starts operating into a Settling Tank Mode, while the first and second SBR Reactors into Modes of Intermittent Aeration Tanks. During this period the arriving waste waters are collected into the accumulating reservoirs formed during the start-up of the controllable airlifts in the first two SBR Reactors. This prevents any insufficiently cleaned waste waters from flowing into the tertiary settling tank. The accumulating reservoirs help the Plant to deal with the sudden and large inflows of waste waters (up to 25 % of the 24-hour consumption).

- Nitrogen and phosphorus are some of the main pollutants in waste waters. In the treatment plant with active sediments and continuous aeration it is possible to establish conditions for simultaneous separation of nitrogen and phosphorus in a biological way. In order to achieve this, it is necessary to ensure the alternation of conditions for desoxidation and oxidation of active sediments aged more than 25 days. In view of the small volumes of the treatment facility and the impossibility to combine the living conditions of the aerobic and anaerobic micro-organisms in the active sediments, it is not recommendable to create anaerobic zones. It is more efficient to alternate the desoxidation and oxidation modes in the waste water treatment process. Under such conditions, facultative micro-organisms develop, which actively participate in both aerobic and anaerobic treatment processes. Thus the quantity of aerobic sediments is increased in the system and nitrogen and phosphorus are effectively separated. BIOTAL System has a self-regulating hydro-pneumatic system ensuring the circulation of sediments between the separate zones at intensity corresponding to the quantity of arriving waste water. The system allows corrections to be made in the sediment re-circulation level and the quantity of dissolved oxygen in each zone separately. The separation of nitrogen by denitration involves a deep nitrification of the ammonia nitrogen and the availability of easily oxidisable organic substances in the waste waters. In order to ensure effective denitration, it is necessary to have a certain ratio of BOD, nitrites, nitrates, easily oxidisable substrate and a certain quantity of dissolved oxygen. It is impossible to maintain optimal ratio of these indicators, especially under conditions of highly variable fluctuations in the quantity and composition of arriving waste waters. There is re-circulation between the zones of BIOTAL Plants even during periods without any inflow of waste waters. Thus, the mixture of sediments with constantly changing indicators gets into one and the same zone numerous times and eventually we get effective denitration. As the nitrites and nitrates in the returned active sediments get into anoxic, not anaerobic, conditions, they are not reduced to ammonia nitrogen.

- The biological separation of phosphorus is achieved mainly thanks to the separation of surplus active sediments, where it is accumulated through РРbacteria. The ordinary active sediments contain 1,5 2% phosphorus, while the sediments, which are periodically treated in oxygen and anoxic conditions, phosphorus is accumulated into РР-bacteria in large quantities (6 8 %). The surplus active sediments in BIOTAL Plants are automatically separated by the aerobic zone because the phosphorus accumulated in РР-bacteria in the aerobic zone dissolves as a result of the anoxic conditions. In addition, the accumulation of a large quantity of active sediments in the system can cause secondary water pollution.

- Because of the high age of the active sediments (more than 25 days) and, respectively, their high mineralization, the dehydration of the surplus active sediments takes place without adding flocculent. The quantity of nitrogen and phosphorus in the waters treated by biological treatment plants depends also on the outflow of small particles of active sediments from the settling tank. BIOTAL Plants have a tertiary settling tank, which retains the tiny sediments, while a special airlift ensures their transfer to the Plant entrance.

- Operation of BIOTAL Plants in winter. The System is mainly designed to treat domestic and sewage waste waters at a temperature sufficient for biological treatment. In addition, the process of biological treatment is accompanied by heat release, and the air in the compressor heats up when compressed, thus further warming up the sediments in the system.

- Operation of BIOTAL Plants during electricity blackouts. In such cases the accumulating reservoirs are filled up and the treated waste waters are gradually pushed out of the system. The Plant also operates as a five-grade settling tank, which can effectively retain oils and floating particles, thus protecting the drainage fields from silting. Even in the event of a long blackout period, after electricity is restored, the system can restore its normal operation in several days without any additional measures to be taken.

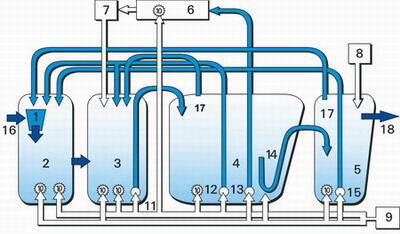

1. Accepting container, 2. Bioreactor SBR-of the 1st stage, 3. Bioreactor SBRof the 2nd stage, 4. Bioreactor SBR of the 3rd stage, 5. Tertiary settling tank, 6. Aerobic stabilizer of waste active sludge, 7. Capacity of waste active sludge, 8. Module of desinfecting of water, 9. Compressors, 10. Aerators, 11. Airlift of the sludge mixes, 12. Airlift of the returned active sludge, 13. Automatic disposal of superfluous active sludge 14. Pumping-out of purified sewage, 15. Airlift for extracting of sludge from tertiary settling tank, 16. Inflow of waste water, 17. Foam, 18. Outflow of purified water

BIOTAL Plant itself operates as three consecutively connected waste water biological treatment plants, where the last SBR Reactor periodically switches from a settling mode of operation with subsequent pumping out of treated waste waters into the operating mode of a tertiary settling tank or a self-cleaning filter for further cleaning.

Waste waters enter the large waste catching chamber, where the wastes undergo an intensive aeration and as a result most of the large wastes (such as toilet paper, etc.) are ground down. The water, free of large wastes, flows into zone І, where some of the returned active sediments are fed from zone ІІІ by airlift (14), as well as sediment from zone ІV, and the foam pushed upwards while the treated waste waters are pumped out by airlift (15). In zone `І` the waste water is partially cleaned biologically, undergoing numerous alternating cycles of aeration and mixing in an air-deficient environment; a process of denitration also takes place here as there are available nitrites and nitrates in the returned active sediments and easily oxidizable organic substances in the arriving waste waters.

The mixture, after being treated in zone І, passes into zone ІІ, where the other part of the returned active sediments is received through airlift (14), which makes it possible to protect this part of the sediments from the negative impact of the toxic substances entering the system. Also, the foam from zone III is also pushed to zone ІІ while the sediments are being pumped out to zone ІІІ by airlift (13). In zone ІІ, similarly to zone І, the sediment mixture undergoes numerous alternating cycles of aeration and mixing. As more than 50% of the organic materials are oxidized in zone І, a nitrification process begins in zone ІІ. As both nitrites and nitrates enter zone II and zone I with the returned active sediments, there are two parallel processes in these zones nitrification and denitration. The nitrification process becomes dominant in the oxidation process. The partially treated mixture is transferred from zone ІІ, through airlift (13), to zone ІІІ, together with gases (carbon dioxide, etc.) formed during the process of waste water treatment in zones І and ІІ, and accompanied by an oxygen saturation of the sediment mixtures due to the interaction with the air. As the content of organic materials in zone III is low, here there is mainly oxidation of those organic substances, which cannot be easily oxidized, as well as nitrification. The treatment process control allows for the ammonia nitrogen to be oxidized primarily to nitrites (redox-potential up to 100), which allows for a faster and more efficient denitration (the chain of nitrite reduction to gas-like nitrogen in this case is shorter than with the nitrates). In zone ІІІ, similarly to zones І and ІІ, the sediment mixture undergoes numerous alternating cycles of aeration and mixing; in addition, there is also settling with subsequent pumping out of treated waste waters by airlift (15) to tertiary settling tank ІV. Airlift (15) also blows the foam in zone ІІІ. While the treated waste waters are pumped out to the tertiary settling tank by airlift (15), airlift (17) pumps out the sediments from zone ІV into zone І. The treated waste waters are discharged by the system.

- They do not require a special sanitary vehicle to ship the treatment products.

- As a result of the treatment process, the machines make two final products, both suitable for a direct end consumption:

- Service water, which can be further used;

- Organic-mineral fertilizer in the form of stabilized and dehydrated surplus active sediments;

- Thanks to the design of the treatment technology, no methane and hydrogen sulfide are released during operation, and that`s why there are no unpleasant smells at any stage of the waste water treatment, which allows the system to be installed in the immediate vicinity to the serviced site.

- The systems are completely automatic and do not require any full-time service personnel. The treatment process is controlled by a Mitsubishi controller, which allows the optimization of the operating process regarding the consumption of electric power and element operating resources; in particular, it ensures the consecutive automatic switching of the system into first, and then into second, Economy Mode of Operation, if there are no incoming waste waters after 1 and 24 hours, respectively, and into a Forced Mode of Operation if waste water quantity is bigger than the design value. A Telko sediment indicator maintains constant concentration of active sediments. The controller display shows the actual system operation the waste water treatment phase of the system at a certain time, the operating facilities, the Mode of Operation of the System, (Economy, Normal or Forced). There is also emergency alarm in the following cases:

- Electric blackout;

- Breakdown of any of the units;

- The receiving chamber is full with rough sediments;

- The filter bags are full with surplus active sediments;

- In case of an electric blackout, during the first 24 hours the system discharges the water treated earlier. Then it begins to function as a multi-level settling tank, thus ensuring that waste waters are cleaned from oils and floating dirt the main enemies to all drainage systems. When the electric supply is restored, the system again switches into a normal mode of operation.

- Thanks to the specific features of the technological process, the system retains the arriving waters with high concentrations of chemical substances (such as chlorine, manganese, etc.), used for cleaning the drinking water treatment systems, which allows the system to be used in high-technological water supply and sewage systems.

- By controllable airlifts the system creates an accumulating reservoir, which ensures that sudden and large inflow of water will also be received thus avoiding the discharge of unprocessed water at the exit. Thus, it is guaranteed that even the strictest requirements to small-size treatment facilities are met.

- Surplus sediments are dehydrated without flocculent, and the surplus water from the sediments is returned to the system receiving chamber.

- The system is made from polypropylene, which is chemically inactive, non-corrosive, watertight, it is small in size and weight, which reduces the construction and installation costs.

- All system elements, which may require repair work, are removable and, therefore, it is not necessary to stop the operation of the system or pump out the water during repair work.

- During start-up and launching and set-up operations, the system does not need a flow of sewage water, and thus the discharge of any untreated waste waters is avoided during set-up operations.

- If there are higher requirements to the quality of treated waters, the system can be equipped with a self-cleaning filter and an ultraviolet decontamination unit, and the cleaning water will be returned to the receiving chamber.

- It is possible to have a cascade connection of BIOTAL Systems, when it is necessary to treat large quantities of waste waters.

- The noise level during the operation of the compressor of systems of a capacity from 1 to 5 m3/24-hour-period is compatible with the noise made by an ordinary refrigerator. The compressor simultaneously ventilates the room it is installed in.

- Thanks to their new technical solutions, high reliability and long operation period, the systems can operate for a long time with a high quality and low consumption of electric power by ensuring high-quality treatment of waste waters, irrespective of their variable parameters at arrival, such as flow rate, time and composition.

The automation of the BIOTAL Plant of a capacity of 1 to 10 m3/24-hour-period ensures four direct links and three feedback links:

- direct links:

- compressor control;

- control of electric magnetic valve for pumping out treated waste waters;

- control of electric magnetic valve for separation of surplus active sediments;

- control of electric magnetic valve for filter cleaning (if there is such);

- feedbacks:

- receiving signals from the level indicator, which is responsible for switching the system into First (after 1 hour) and Second (after 24 hours) Economy Mode of Operation;

- receiving signals from the level indicator, which is responsible for switching the system into a Forced Mode of Operation when the waste water quantity exceeds the design quantity;

- receiving signals from the system active sediment quantity control indicator, which is responsible for switching airlift (16) electric magnetic valve, which separates the surplus sediments to the sediment tank in case the determined active sediment quantity is exceeded.

There are five waste water treatment phases in the system: mixing in an anaerobic environment, aeration of sediment mixtures, settling, pumping out of the treated waste waters and pumping out of surplus sediments.

Mixing Phase: it is carried out in all three SBR Reactors by periodic short (to ensure that the oxygen in the sediment mixtures does not exceed 0,5 ml/l) start-up of aerators. During the period of the short start-up of aerators there is also re-circulation of sediment mixtures between the three reactors. The running time and the idle time are set during the automation set-up.

Aeration phase: there is aeration in all three SBR Reactors with a simultaneous re-circulation of sediment mixtures between the reactors. Controllable airlift (13) during the preceding cycles has reduced the level in Reactors І and ІІ, thus creating first and second accumulating reservoirs. The waste waters arriving into the system are collected in these reservoirs during the phases of mixing, aeration, pumping out of treated waste waters and surplus sediments. In its turn, controllable airlift (15), during the phase of pumping out of the treated waste waters, reduces the water level in the third SBR Reactor, thus creating a third accumulating reservoir. All these three accumulating reservoirs collect the arriving waste waters during the mixing and aeration phases of the system. Thanks to these accumulating reservoirs, the sediment mixture does not get into the tertiary settling tank until the settling process is completed in the third SBR Reactor and then the treated waste waters are pumped out by airlift (15) into the tertiary settling tank during the treated water pumping-out phase.

Settling Phase: during this phase (in BIOTAL Plants from 1 to 10 m3/24-hour-period) all elements are switched off. The third SBR Reactor switches into a Mode of Operation as a secondary settling tank, while the arriving waste waters are collected in the accumulating reservoirs of the first and second Reactors.

Treated Waste Water Pumping-out Phase: during this phase the treated waste waters are pumped out by airlift (15) from the third SBR Reactor to tertiary settling tank ІV, accompanied with aeration in І and ІІ SBR Reactors.

Surplus Active Sediment Pumping-out Phase: this phase (in BIOTAL Plants from 1 to 10 m3/24-hour-period) begins at the same time with the Treated Waste Water Pumping-out Phase but it is shorter. The surplus active sediments are pumped out either into a special reservoir connected to the receiving chamber by a spillway for the sediment surplus water, or into filter bags, which are drained in ІІ SBR Reactor.