- Home

- Companies

- BIOWORKS Verfahrenstechnik GmbH

- Products

- BIOWORKS - Clarifier - Integrated ...

BIOWORKS - Clarifier - Integrated Wastewater Settling Solution

The BIOWORKS Clarifier is an advanced integrated wastewater treatment solution distinct from conventional settling tanks. This clarifier is strategically placed at the terminus of the activated sludge basin, divided by a shared wall, allowing seamless flow of the activated sludge/water mixture into its rectangular structure. The ratio of length to width is approximately 4:1, ensuring efficient settling dynamics. Sludge collects at the base of the clarifier, where it is extracted and recirculated by a moving scraping bridge, enhancing treatment efficiency. The effluent passes through oppositely aligned openings, maintaining a tranquil flow to prevent resuspension of settled sludge. This design streamlines operations by negating the need for additional pipes. Capable of handling up to 2,200 m³/h per unit, the BIOWORKS® Clarifier demonstrates improved operational efficacy over traditional circular settlers.

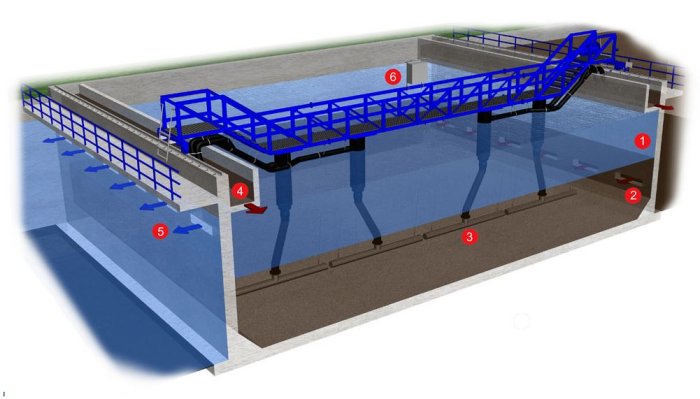

Different from conventional settling tanks, the BIOWORKS® clarifier is an integrated solution. The clarifier structure is located right at the end of the activated sludge basin and is separated from that by a common wall (1). The clarifier structure is of a rectangular geometry, with a length to width ratio of around 4:1. The activated sludge/water mixture streams through openings (2) in the common wall into the clarifier. Activated sludge will settle at the bottom of the clarifier and is sucked from the bottom (3) and pumped back to the inlet as return sludge (4), by a moving sucking scraper bridge (5) which moves alongside the clarifier back and forth. The clear water at the top of the water body water inside the clarifier passes the effluent openings (6) which are aligned at the opposite wall of the influent.

The number and location of the openings ensure that there is very slow and calm current in the clarifier. This avoids any potential stirrup of sludge in the settling zone. Our design eliminates the need for interconnecting pipes between activated sludge basin and clarifier.

In comparison to conventional circular settlers, the BIOWORKS® clarifier shows the following advantages:

- No hydraulic disturbance of the influent zone, as the inflowing water has very low velocity, due to the large inflow area at the common wall

- Much more economic use of the available land

- Elimination of interconnecting pipes and return sludge pump stations

- Simpler civil construction than circular clarifiers, particular with large diameters

BIOWORKS® clarifiers were built for capacities up to 2.200 m3/h (as single unit)