- Home

- Companies

- J.F. Brennan Co., Inc.

- Products

- Brennan - Model BCS - Broadcast Capping ...

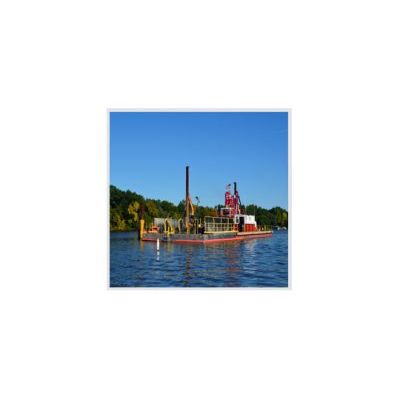

Brennan - Model BCS -Broadcast Capping System

Brennan has revolutionized the capping industry with its newly patented Broadcast Capping System (BCS™). This system uses the principles of hydraulic transport to deliver clean sand and gravel to a distribution barge where it is rapidly dewatered and unobtrusively spread over the bottom of the waterway. Brennan’s capping system can accurately spread materials up to 3 inches in diameter, while achieving a homogenous thickness with even distribution.

The BCS is a preferable method over mechanical capping where there are shallow water environments and when the accuracy of placement of capping materials is critical. Also, the BCS is preferable when there are concerns about mud wave distribution of in-situ sediments. Brennan has found the BCS to be most advantageous in its deployment when materials below 3 inches in size are required for cap construction. In situations where smaller aggregates are used to construct a cap, the BCS will reduce labor and equipment, thereby constructing a higher quality cap at less cost.

The BCS method was developed by Brennan in 2004 to accurately place thin environmental caps/covers over very soft contaminated sediments. The system was developed so that cap material could be placed without intermixing with soft, low density, in-situ sediments.

- Able to accurately place a sand cover over soft sediment bottoms with minimal intermixing

- Virtually eliminates suspension of in-situ sediments

- Most cost effective over large cap areas

- Onboard tracking system records thickness, volume, and position of material placement

- Strategically placed spuds that will not pierce the cap once it is placed

The Brennan BCS uses several built-in quality control processes while the cap is being applied. Once dewatered, the volume of sand is measured and recorded prior to being placed, allowing flexibility for thickness application. The onboard navigation system is similar to that used on Brennan dredges that allow the operator to see where he or she is placing in real time as well as what areas have been completed. Additionally, the plant has several sample points set up to capture real-time thickness measurements that are checked every time the plant progresses.