-

Electrostatic / triboelectric

-

Compact design

-

Detection of only moving material - not influenced by deposits

-

Relay and 4...20mA version

-

High temperature version (200°C / 392°F)

-

Sensitivity 0.1 mg/m3 (all dust types)

-

Flow displayed by LED-bar (relay version)

-

Reliable, longterm stable, maintenance free

-

Low cost

- Home

- Companies

- DYNA Instruments GmbH (MÜTEC ...

- Products

- DYNA - Model DYNAguard GM - Broken Bag ...

DYNA - Model DYNAguard GM -Broken Bag Detector and Filter Monitor

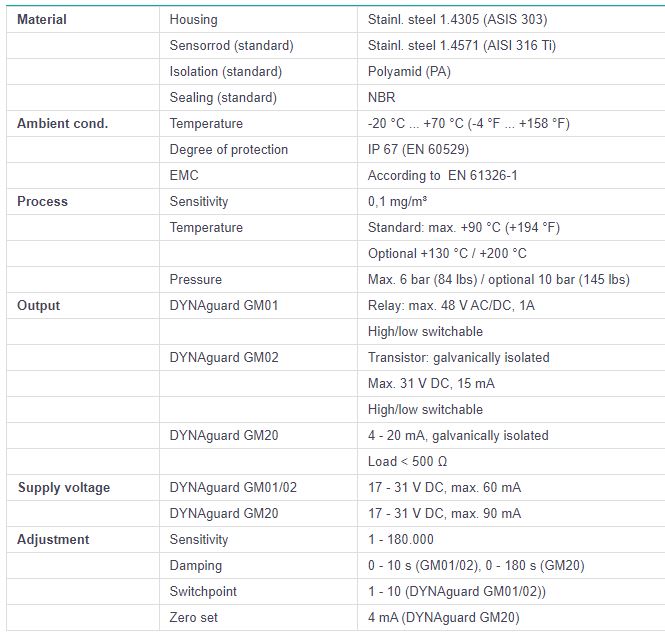

The DYNAguard GM is an advanced broken bag detector and filter monitor, designed for detecting filter malfunctions such as broken bags or installation errors. Operating on a modified triboelectric principle, it detects particles interacting with its sensing rod, focusing solely on moving particles and ignoring static deposits. This ensures accurate detection and monitoring. The DYNAguard GM is available in three electronic versions, offering analogue (GM20), relay (GM01), or transistor (GM02) outputs. Users can easily adapt the device under normal conditions with switches and a potentiometer, making the alarm level adjustable. The sensor rod length should be tailored to 1/3 to 2/3 of the duct diameter, up to a maximum of 800mm. Installation is straightforward; the device is installed on the clean gas side downstream the filter in a metal duct. Straight duct segments upstream and downstream are recommended for optimal performance. This device is reliable, maintenance-free, and cost-effective, making it ideal for consistent dust measurement over the long term.The broken bag detector DYNAguard GM is used for the detection of filter malfunction e.g. a broken bag or an installation error.

The DYNAguard technology is based on a modified triboelectric principle detecting particles interacting with the sensing rod and such particles just passing the rod. Build up on the rod surface will not be detected, only moving particles generate a flow rate proportional signal which is monitored by the electronics. Three electronics versions are available with analogue (GM20), relay (GM01) or transistor (GM02) output. Adaptation is done under normal conditions by switches and potentiometer, DYNAguard's alarm level (GM01, GM02) can be set above this background. Signal damping is selectable by the user.

The length of the sensor rod should be 1/3 to 2/3 of the duct diameter, 800mm maximum.

The broken bag detector is installed on the clean gas side downstream the filter at a metal duct by welding on of a thread bush boring through the duct wall and screwing in DYNAguard. Upstream and downstream the sensor at least three duct diameters should be straight without any fittings like valves or dampers.

Comissioning is simple and requires no tools or speciali equipment.

Proven technology for reliable dust measurement.