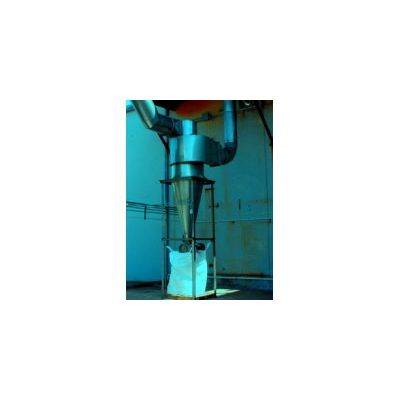

Bulk Bag

Intermediate Bulk Containers (IBC) can contain solids or liquids and can be soft or hard sided (totes) Material is usually dispensed from them in a Loss-in-weight application.

Intermediate Bulk Container (IBC)

Dispensing is also associated with loss-of-weight systems. IBCs are syspended by load points to weigh the material dispensed into receiving containers. Hardy controllers open and close the discharge gates while weighing the loss of ingredients. IBCs are often exchanged in the middle of filling when the first IBC is emptied. A Hardy controller retains the amount dispensed from the first IBC in memory so that it knows how much material is required from the second IBC to complete the desired weight. Without this feature, material is wasted by not completely emptying the IBC or by over filling when switching.

Instrumentation and Control

Hardy`s instrumentation for filling and dispensing includes weight, rate, and batch controllers. They can be stand alone systems or connected to host computers or programmable logic controllers (PLCs). Total net weight can be tracked with Hardy`s totalizer feature, which keeps track of the total amount of net weight that has been filled or dispensed. Bar graphs give a visualization of the amount being filled, dispensed or totalized. In addition to filling and dispensing, Hardy controllers can also be used to control or monitor the rate of flow of material and batch ingredients.

Accuracy

High resolution and fast update rates in Hardy`s controllers allow for precise cut-offs required in filling and dispensing processes to ensure accurate weighments. Example: if one hundred pound bags of flour are to be filled to a quarter of a pound, the scale needs to be able to be read in tenth of a pound increments. The scale must update faster then the rate material is entering or leaving it.

Hardy controllers also have the ability to account for the in-flight material that is not yet on the scale when the valve or gate is closed (preact). A user-selectable preact can stop the filling or dispensing process earlier in order to compensate for the in-flight material, so it doesn`t over shoot the final desired weight. If the final weight falls under the desired amount, Hardy`s "jog" feature slightly opens the gate or valve for a short period of time to bring the weight into tolerance.

Speed

Accuracy of filling and dispensing is increased even more with the dual speed capabilities of Hardy`s controllers. A fast or bulk speed is used for the majority of the process cycle, where valves or gates are wide open to allow maximum flow, and a slow or dribble speed is used for a short duration at the end of a cycle, where the valves or gates are nearly closed. The slow or dribble speed allows for a higher accuracy of hitting the final desired weight without under or over shooting it. As with a gas station pump, most of the material is dispensed quickly and the last is dribbled in to allow the controller to accurately cut off the flow.

Alarms/Tolerance Checks

Alarms of various types can be set to notify operators. For example, if the controller energizes the feed output and the gate doesn`t open or there is no more material available, an alarm will sound. Alarms are also set to notify the operator if the material falls over or under the weight tolerance range. The filling or dispensing process can be configured to stop when an alarm goes off.

WAVERSAVER Ignores Vibration

Equipment used in filling and dispensing operations can cause unwanted plant and process vibration. Conveyors moving containers through the process, the opening and closing of discharge gates, feeders dispensing material and augers moving material and refill operations all produce vibration. Hardy`s WAVERSAVER technology ignores vibration signals to provide quick and accurate weight readings.

Calibration Made Easy

Hardy`s C2, Second Generation Calibration eliminates costly scale calibration fees associated with filling and dispensing systems. C2 allows you to electronically calibrate without test weights, even with material in your vessel.

The C2 system consists of Hardy C2 certified load points, weight controllers, junction boxes and cabling to make scale calibration easier than ever before. Each C2 certified load point contains digital information detailing its unique performance characteristics. The C2 system uses these characteristics to electronically calibrate the scale. When power is applied, the weight controller automatically searches for C2 certified load points and saves the data to memory. A reference point is entered by the operator and the scale is fully calibrated.

The C2 system reduces downtime for installation and repairs, and eliminates test weight related injuries. In addition, it ends material substitution headaches, including contamination and waste disposal issues.

Data Security

Each Hardy weight controller includes a Secure Memory Module which automatically stores and protects critical data including calibration, setup and operating parameters. If the instrument ever needs replacement, the Secure Memory Module can be transferred to another weight controller and all critical data is restored, making your filling and dispensing system operational within minutes.