Buoyancy Enhanced Membrane Filtration

A Spin on Filtration. Swirltex’s patented buoyancy-enhanced membrane solution is suitable for a wide variety of wastewater treatment applications. Our innovative process turns a liability into an essential resource. The Swirltex technology is designed to allow for greater flow through a smaller surface area. The unique flow pattern keeps contaminants off the surface of the membrane, reducing fouling and therefore resulting in significant cost savings.

Our proprietary buoyancy-based membrane filtration has

revolutionized the way industries can utilize wastewater. The Swirltex system

is designed to be compact, such that it can fit within a modular unit for ease

of transport and flexibility. The incoming wastewater is pumped into the

Swirltex system at a considerably lower energy rate than a traditional membrane

system. The liquid stream is bombarded with gas microbubbles, creating a

flotation effect for the contaminants. The contaminants bind to the gas

bubbles, thus dramatically increasing their buoyancy and allowing them to

float. Both the liquid stream and

buoyant contaminants enter the tubular membrane, where the fluid is spun within

each tube to create a vortex— hence why our solution is called Swirltex. As the stream spins, the lighter

contaminants, including the buoyant solids, are forced into the center of the

membrane tube while the cleaner water is forced toward the membrane walls. The

vortex creates an annular flow-pattern, naturally separating the liquid stream

from the gas contaminants, yielding the clean ultra filtered water. This vortex

motion increases permeate flux by increasing the shear force against the

membrane surface. It also reduces fouling since contaminants are predominantly

prevented from touching the membrane surface.

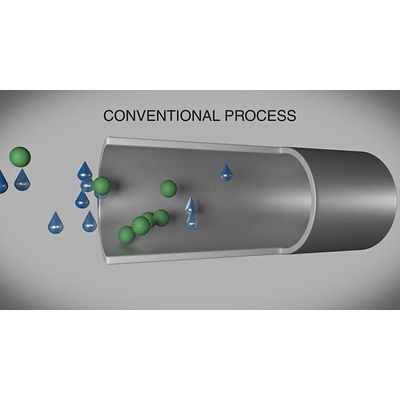

Traditional tubular membranes can consistently filter to

high-quality water level. However, they are limited by their efficiency and

their tendency to foul or build up with solids. They require constant cleaning

cycles as well as frequent membrane replacements. Swirltex uses off-the-shelf

membranes in a novel way to enable them to be used in difficult wastewater

applications and facilitate water re-use. Swirltex’s unique membrane system

separates solids and liquids based on buoyancy, allowing for higher production

rates and higher quality effluent. The ability to manipulate the buoyancy of

contaminants within the liquid stream allows Swirltex to treat a wide range of

wastewater types that would otherwise not be reusable. The Swirltex technology greatly improves the

efficiency of tubular membranes through an induced centrifugal flow pattern,

resulting in higher recovery at lower energy requirement and minimal fouling

induced flux decline through buoyancy manipulation.

Swirltex builds custom wastewater treatment systems for a wide range of applications. The unique membrane system separates solids and liquids based on buoyancy, allowing for higher production rates and higher quality effluent.

The ability to manipulate the buoyancy of contaminants within the liquid stream allows Swirltex to treat a wide range of wastewater types that would otherwise not be re-usable. In addition, the system consumes a fraction of the energy compared to conventional water treatment methods.