- Home

- Companies

- Topas GmbH

- Products

- Capillary Flow Porometer - Model PSM ...

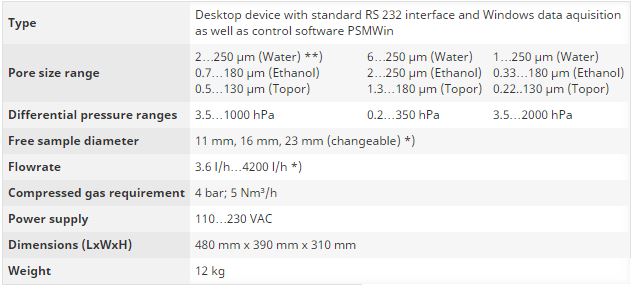

Capillary Flow Porometer - Model PSM 165 -Pore Diameter Distribution Measurement

Amongst others the following three main parameters describing the inner structure of the material can be obtained with this compact pore size analyzer:

- Bubble Point (largest pore diameter) : Pressure drop at which the wetted sample is starting to become gas permeable.

- Pore Size Distribution : Permeability weighted pore diameter distribution calculated from wet flow curve (pressure drop vs. volumetric flow rate of the wet sample) and dry flow curve (similar to wet flow, but obtained on a dry sample).

- Mean Flow Pore Size : Pore diameter corresponding to the pressure drop where the wet flow value is half (50%) of the dry flow.

- Nondestructive, structural characterisation of filter media with non-mercury porometric measurement technique

- Several sample holder dimensions for optimal fit to different sample sizes

- Compact instrument design

- Barrier effect and germ retention of textiles – multifilament woven

- Hygiene – capillary effect and suction power of absorbers of sanitary products

- Injection printing – capillary effect and typeface of print-out paper

- Cell cultivation – specific inner surface of carrier materials

- Filter materials – pressure loss characteristics and fractional efficiency

- Name : Primarily Compounds with 12 Carbons

- CAS-Nr. : 86508-42-1

- Formula : Not applicable

- Specific Physical Form : Liquid

- Odor, Color, Grade : Colorless, odorless, liquid

- Specific Gravity / Density : approx. 1.9 g/ml, water = 1

- Viscosity : approx. 2 mm²/s (cSt)

- Melting Point : Not applicable

- Boiling Point : 158 – 173 °C

- Vapour Pressure : approx. 0,4 kPa (3 mmHg) @ 25°C

- Auto ignition Temperature : Not applicable

- Flash Point : Not applicable

- Surface Tension : 16.0 mN/m

The basic principle of a pore size measurement via capillary flow porometry is that liquid filled pores will become gas permeable at a certain pressure, because the liquid has first to be displaced by the gas. This pressure, the so-called bubble point, depends on the surface tension of the liquid and the pore diameter. As real materials almost always show a pore size distribution, the pressure at which the initially liquid filled pores become gas permeable corresponds to the opening pressure of the biggest pores. By further increasing the pressure drop across the material under test and measuring the volumetric flow rate, it is possible to obtain data from which the pore diameter distribution and pore volume can be calculated.