Cequesta - Automated Sludge Press (ASP)

The ASP (Automated Sludge Press) is a powerful wastewater treatment system able to treat many types of industrial wastewater or sludge in one single operation unit. Sludge dewatering treatment is, in simple terms: removing excess liquid from the sludge at minimum expenses and achieving the highest level of dryness. Dealing with mechanical sludge dewatering is a complex issue; it involves both chemical and physical processes. Not all of them completely controlled and understood, some of the process relay on old fashion, trial and error, as the sludge and operational parameters may change along the year.

Sludge dewatering process, can be described, as a long chain of operation links; CW (Cequesta Water) business is focused on one essential link, the sludge thickening and dewatering solution.

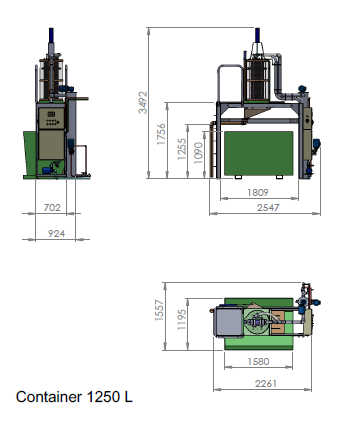

For this Cequesta Water designed the ASP as light, transportable, easy to operate and maintain. CW (Cequesta Water) business is focused on one essential link, the sludge thickening and dewatering solution.

The ASP was designed for low maintenance cost and as such: does not vibrate, no cloths or belt clogging and changing required, and 95% of the components are non-expensive shelf items, all this results in - most of our customers service their own ASP without our involvement.

The ASP operation parameters can be changed according the sludge dewatering characteristics, like feed rate, dosages, press time, etc, all of these by an MMI interface which is a standard supply in each ASP system.

ASP (Automated Sludge Press) a prepackaged, pre-engineered, compact and automatic dewatering solution for various types of sludge.

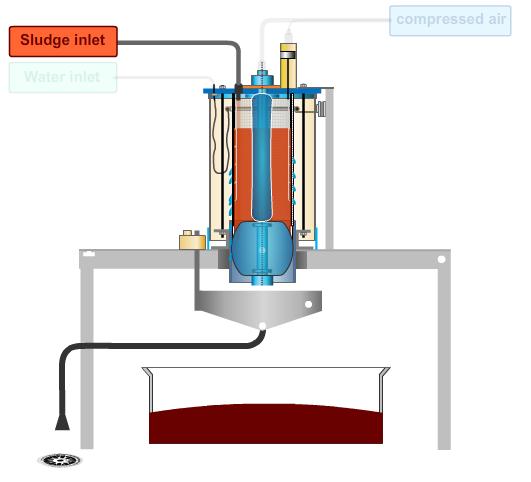

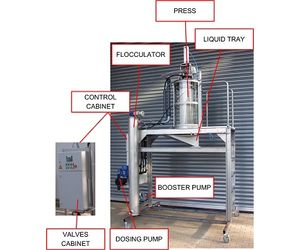

The press is composed of five main subsystems:

- Support Frame

- A stainless steel supporting frame for long service life. This frame supports the press chamber to allow the cake receiving vessel (skip or bag) to be positioned directly under the press chamber thus negating the need for conveyors (conveyor is optional).

- Filtration and dewatering chamber

- Wedge wire cylinder screen

- Pneumatic pressing diaphragm (internal)

- Dry sludge scraper (internal)

- Cleaning mechanism

- Chamber bottom sealing mechanism (internal)

- Process accessories

- Filling pump

- Flocculent dosing pump

- Flocculator

- Transfer Pipe

- Cleaning boosting pump

- Valves

- Sensors

- Pneumatic actuators & control

- Pneumatic (standards) pistons

- Pneumatic valves

- Electrical Controls

- PLC controller

- Limit switches

- Electrical control components i.e.: relays, contactors, timers, sensors, etc..

The press works on a batching cycle principle, controlled by a sophisticated controller.

The program enables the operator to readily change parameters in order to optimize the press operation, increase the throughput or alter the output dryness according to the actual specific sludge being processed.

The controller is featured with the following options:

- Auxiliary pump for filtrate pumping

- Extra dosing pump

- pH control

- Boosting pump connection

- Automatic CIP

- Operation on demand (from level sensing from holding tank)

- Operation by timer (to start and stop automatically)

- Remote monitoring (interact with telemetry)

- Alarms monitoring (interact with telemetry or SMS)

Safety control: The PLC program includes a diagnostic feature that will prevent any faulty operation and allows the operator to fix the problems easily and safely. If a problem occurs, within the cycle, the press will cease operation and an alarm will sound.

The ASP (Automatic Sludge Press) is fully automated, leaving the controller only to supply the sludge source as an inlet tank or pipe, etc. When there is not enough sludge, the press will remain in "Stand By" mode until the next activation.

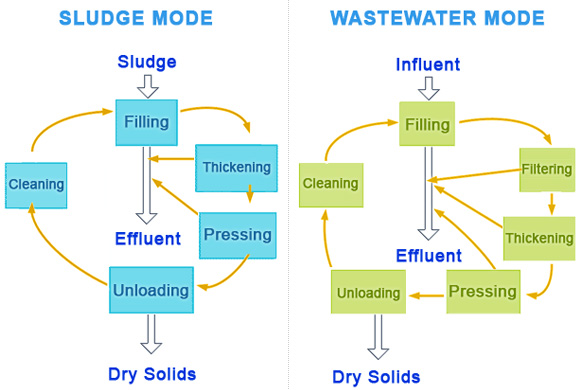

The ASP (Automated Sludge Press) can work in two modes – sludge dewatering and wastewater treatment. Both are completely automated processes and perform solid separation resulting in dry solids.

The diagram shows the process – for the wastewater there is an added step of filtering out the water.

Filling

The base of the wedge screen is blocked by the lower sliding door and sealing membrane.

Sludge is pumped into the mechanical Flocculator where it mixes with flocculent. The flocculated slurry then enters the void between the inner screen and the pressing diaphragm, the excess filtrate is percolated through the screen slots, while the thickened sludge (about 10% DS), is retained internally. The semi dry sludge is accumulated on the bottom of the cylindrical screen and settles upward.

Filtering

Relevant to wastewater mode, the wastewater is filtered through the ASP screen, and the solids retained are simultaneously thickened and later dewatered by the pressing operation.

Thickening

For dewatering mode, the sludge is thickened while filling (merge with filling).

Pressing

When the void is full, a sensor signal stops the filling/thickening sequence and the pressing sequence is started, the flexible membrane is inflated while pushing the solids against the screen surface by a radial force, which is the fastest and most efficient way to dewater slurries.

The excess fluids is drained out externally, this step is time controlled for few minutes with both pressing and pulse pressing steps controlled by the PLC program..

Unloading / Sludge downloading

At the end of the pressing sequence the drain tray swings away, the lower door membrane deflates and the door retracts.

The scraper carriage is then activated cycling up and down the internal surface of the wedge screen dislodging the sludge cake allowing it to fall freely to the collection container below.

Cleaning

After the scraping sequence has been completed the drain tray swings back around ready to capture the cleaning residue.

With the use of both water and air the screen is automatically backwashed by a ring of spray heads moving up and down the outside surface forcing any remaining sludge caught in the screen back into the void and down into the drain tray.

A new filing sequence is started.

The on board PLC enables friendly and smart parameters in order to optimize the press operation.

Note all the processes take place in one compact chamber as well as the automatic cleaning stage. The press incorporates inline coagulation and pH control. The result is a single reactor WWTP (wastewater treatment plant), which produces very clean filtrate and dry sludge, fully automated.