- Home

- Companies

- Cerex Monitoring Solutions, LLC.

- Products

- Cerex - Model UV3000-CRM - Rackmount ...

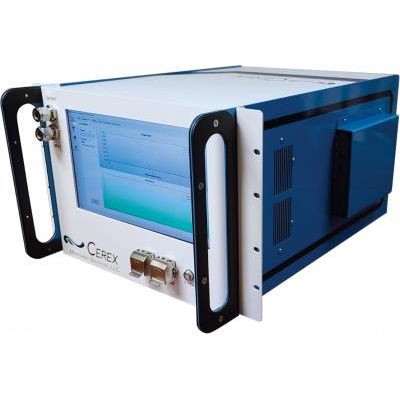

Cerex - Model UV3000-CRM -Rackmount Process Analyzer

Designed to provide high performance analysis for a variety of applications such as Process, Ambient, and Continuous Emission Monitoring in a rack mount configuration.

A collection of UV-DOAS process and stack gas analyzers customizable for almost any application

Based around a proven UVDOAS data acquisition system, each unit is capable of harnessing our proven methods in your environment. Available in Cross Stack, Rackmount, Probe and Zone configurations, the UV 3000 series of analyzers has something for everyone. Choice of materials, sampling pumps, and sample cells are a few options available to the adaptation of the UV 3000.

- Part-per-billion (ppb) level detection limits

- Simultaneous multi-gas capability

- Greater performance than electrochemical and PID technology at a low cost

General

- Measurements: 63.5cm x 54.1cm x 47.25cm. (25in x 21.3in x 18.6in)

- Weight: 66kg (145lbs)

- Material: Stainless Steel

Within each Cerex UV3000 analyzer, a gas sample is drawn in and measured in a fiber coupled external cell connected to a process stream, or via an optional sample pump.

A miniature spectrometer then collects the gas fingerprint data, and Cerex’s proprietary software compares the results to a calibrated reference, or “library spectra”.

Ultimately, an onboard or external PC reports reliable real-time concentration data up to once per second, and stores all spectral data for later post processing or archiving.

The result is near real-time spectral “fingerprints” of all target compounds, with accurate qualitative and quantifiable data of each.

How is this possible? A physics principle known as the Beer-Lambert Law. UV radiation that passes through a gas will “absorb” the gas; thus, when viewed on a spectrograph, a distinct pattern of absorption appears. Each gas has a unique “absorption pattern”, and this, combined with our proprietary photometric Differential Optical Absorption Spectroscopy (DOAS) algorithm, Cerex UV-DOAS analyzers are able to quickly and accurately identify compounds from an air mixture without the need to calibrate or take a clean air background.

Why UV-DOAS?

Ultraviolet spectroscopy principles are similar to common infrared methods, but offer lower detection capability for many chemicals associated with impact on human health. We recommend UV-DOAS based analyzers for a faster, more accurate, and less costly solution for certain compounds and applications.

The Cerex Hound Series has as low as parts-per-billion minimum detection limits and wide dynamic ranges, allowing earlier and more thorough detection of gases than traditional sensor arrays. In comparison to outdated technologies, UV3000 series analyzers feature multi-gas monitoring of individual species, lower detection limits, no water vapor interference, inherent calibration and no sensors to poison.

The system can be span checked at any time, however, the measurement and analysis method employed in this system has the true calibration inherent in the fixed library references. Unless there is a system fault, calibration is never needed. The system is self-compensating for all normal sources of drift found in analyzers including temperature, aging of the lamp, degradation of the optics, etc.

Cerex UV3000 analyzers include a multi-purpose standard library suitable for monitoring dozens of compounds. Custom calibrations are available based on application.

Common applications for the UV3000 include measuring Ammonia (NH3), Chlorine (CL2), Sulfur Dioxide (SO2), and BTEX amongst many more. The UV3000 comes in a NEMA4 rated enclosure for outdoor environments, or a 19 inch rack mount enclosure.

- Continuous Emissions Monitoring

- Extractive Hot/Wet or Cool/Dry

- DeSOx, DeNOx, Ammonia Slip Monitoring

- Process Monitoring

- Ambient Air Monitoring