- Home

- Companies

- Cerex Monitoring Solutions, LLC.

- Products

- Cerex - UV Sentry Open-Path Gas ...

Cerex - UV Sentry Open-Path Gas Analyzer

The Cerex UV SENTRY is an open-path gas analyzer that specializes in sensitive detection of key hazardous emissions such as Benzene and Chlorine over 1000+ meters of fence-line paths. It sets the industry standard for time-resolved, gap-less fugitive emissions and chemical emergency monitoring across fence lines, around process units, and around tank farms. As the most cost-effective solution for part-per-trillion detection limits of Benzene-specific monitoring, the UV SENTRY is deployed world-wide by some of the world’s largest petrochemical companies, oil refineries, and government agencies.

- Benzene and other gases down to parts-per-trillion minimum detection limits (gas specific) within seconds – real-time data output

- Low cost of ownership, no-maintenance design; only consumables are dust filters and UV lamp

- Simple, inherent calibration verification using built-in flow cell

- Raw data auto-archived in .csv format for instant analysis, compared to “black box” solutions

- Remote control over network or internet – cellular-ready

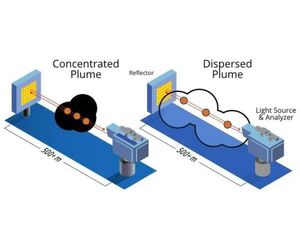

The Cerex UV Sentry operates using a technique known as UV-DOAS (Ultra Violet Differential Optical Absorption Spectroscopy). A beam of ultraviolet light is sent from the UV Sentry through the open air, and through any ambient gas samples, to a retroreflector array up to 1300 meters away. The light is then reflected by the retroreflector array and returns to the UV Sentry.

Due to a physics principle known as the Beer-Lambert Law, and algorithms within Cerex’s software, the gas samples that the light passed through on the way back to the UV Sentry is converted into useable data. Gas samples are identified and quantified in real-time, and can be viewed remotely anytime, anywhere.

Combining the UV-DOAS technique with parts per trillion to parts per billion detection limits makes the Cerex UV Sentry one of the most affordable and accurate solutions for perimeter & fenceline monitoring. Dozens of gases and compounds can be monitored within the UV light spectrum, notably Benzene and Chlorine, for a valuable low-cost solution.

(Above) Process of open-path monitoring (depicted with a Cerex UV Sentry). The Cerex UV Sentry mounts to a precision pan and tilt head which may be used with a tripod for rapid deployment, or with a fixed mount for permanent installations. The retro-reflector array is housed in a NEMA enclosure and may be tripod or fixed mounted to a mast, pole or superstructure. Monitoring path lengths are typically configured to meet minimum detection limits required for the project. Paths to 1 km are possible. Gases present in the beam path are identified and quantified in near real time. Credit: STI

Dozens of compounds can be targeted with a UV-DOAS configured library. Combined with Cerex’s real-time analysis software, up to 50 compounds can be monitored simultaneously. Each Cerex UV-DOAS analyzer includes free setup of a custom-tailored library that best fits your application.

The UV Sentry has as low as parts per trillion to parts per billion minimum detection limits and wide dynamic ranges, allowing earlier and more thorough detection of gases than traditional sensor arrays.

- Acetaldehyde

- Acrolein

- Ammonia

- Benzene

- 1,3-Butadiene

- Carbon Disulfide

- Chlorine

- Chlorine Dioxide

- Ethylbenzene

- Formaldehyde

- Hydrogen Sulfide

- Naphthalene

- Nitric Oxide

- Nitrogen Dioxide

- Ozone

- Phenol

- Styrene

- Sulfur Dioxide

- Toluene

- m-, o-, p-Xylenes

*NOTE: For detection of gaseous compounds not available within the UV spectrum, we recommend the Cerex AIR SENTRY – an open-path analyzer that uses FTIR (Fourier Transform Infrared). Find more information about UV-DOAS and FTIR techniques here.

Cerex recognizes that detailed gas monitoring results need to be reliable and available quickly to various stakeholders. For this reason, Cerex engineers developed software to accurately detect and display gases within the air in real time from any location.

A user can see results in numerous ways: on-site via a touchscreen computer that is included on every analyzer, or remotely on a phone, tablet, or computer anywhere in the world via a virtual connection. GPS and cellular configurations make this possible in remote environments.

All data is automatically saved in an easy to access .csv file; this feature helps our clients in various ways - from daily use to crucial events such as evidence in court.

Learn more about the benefits of our proprietary analysis software here.

Multi-gas monitoring over linear distances exceeding 1000 meters, minimal infrastructure requirements and direct integration with existing factory management systems provide cost effective installation. Low consumables, field proven service life, inherent calibration and “hands off” operation provide low cost of ownership.

Parts per trillion to low parts per billion detection limits and wide dynamic ranges enhance early leak detection and release characterization. Concentrations of gases below the detection thresholds of traditional sensor arrays are readily detectable with the UV Sentry analyzer. Early detection translates into quicker response times, reduced environmental impact, decreased plant downtime and reduced exposure of site personnel and the community.

Species include gases commonly of concern in Chemical Manufacturing, Refinery Operations, Acid Plant Operations and Ore Processing, Concrete Manufacturing, Mining Operations, Environmental Remediation and More…

With part per trillion minimum detection limits for Benzene, the UV Sentry allows regulatory compliance for SCAQMD Rule 1180 and BAAQMD Rule 12-15 BTEX monitoring. It also represents a stand-alone solution for alternative MACT compliance for US EPA Method 325 refinery fence-line benzene monitoring.

As a stand alone analyzer for BTEX, Acrolein, Formaldehyde, SO2, Styrene… or as a component within a larger analyzer array including the Cerex AirSentry FTIR for Ammonia, Alkanes, Formaldehyde, HF, HCN, etc… Cerex offers comprehensive monitoring compliance solutions for Federal, State and Regional monitoring requirements.

All Applications- Acid Plant Monitoring

- Benzene, Toluene, and Xylenes (BTEX)

- Brownfield Remediation

- Chemical Depot Monitoring

- Chlorine Monitoring

- Electrowinning Emissions Monitoring

- Fence-line Monitoring System (FLMS)

- Manufactured Gas Plant Remediation (MGP)

- Perimeter Ambient Monitoring System (PAMS)

- Superfund Site Remediation

- Tank Farm Monitoring

- Regulation Compliance

- EPA Method 325

- 40 CFR 63.658 (MACT)

- SCAQMD Rule 1180

- BAAQMD Rule 12-15