- Home

- Companies

- Kingfisher Industrial Ltd

- Products

- Kingfisher - Model K-CLAD - Chromium ...

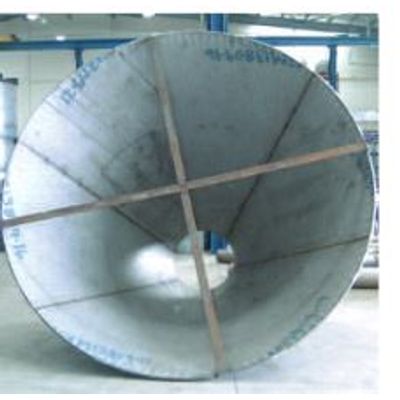

Kingfisher - Model K-CLAD -Chromium Carbide Deposit Lining System

K-CLAD chromium carbide deposit is used to protect plant and equipment from impact and sliding induced abrasion associated with both light and heavy industrial processes.

Manufacture

Various methods of manufacture have evolved over the years since the introduction of chromium carbide overlay deposit. Currently, all popular manufacturing methods can be characterized as either open arc fusion or submerged arc fusion bonded processes. Open arc welding is accomplished with a cored wire of the proper diameter. No gas or flux is added to the process. All the slag, flux, gas cover, and alloys are included within the core of the tube. The wire is fabricated from a low carbon strip and the critical ingredients are added during the fabrication. Process control is quite simple since only standard arc voltages, currents and wire feed rates require attention. Deposits are relatively smooth, but are susceptible to roughness and poor tie-in between the weld beads.

Submerged arc welding is accomplished through the use of a solid or cored wire and added flux. The arc melts both the wire and the flux and forms a weld bead and an easily removable slag covering. This fusion bond welding process achieves smooth deposits with extremely shallow peaks and valleys, process control and deposit consistency.

Despite many claims by manufacturers of the open arc process, it is generally proven that the submerged arc process offers a greater degree of wear resistance during the application of the first pass due to lesser dilution rates into the base metal.

Application

K-CLAD can be used in virtually every area of industrial process where bulk solid materials are being conveyed or processed. From the face of the quarry to the cleaning operations associated with gas scrubbing, K-CLAD has been used successfully in extending the service life of plant and equipment. With a hardness rating of between 550 and 650 BHN it can be used to protect excavating equipment along with extended the service life critical plant and equipment.

Forms of supply

K-CLAD can be supplied in sheet form, produced in sizes up to 3mtr by 1,5mtr and in standard thicknesses ranging from 6mm to 25mm thick. Likewise, deposits can be applied directly onto the substrate of plant and equipment utilising standard and purpose built manipulators.

Protection can also be applied by means of depositing hardfacing directly onto metallic surfaces using MMA, MIG or flux cored wire utilising conventional welding equipment.

Installation

K-CLAD liner plates can be applied by means of welding them directly on to the steel surface or they can be fixed using traditional methods such as the use of counter sunk set pins being placed into a tapered hole and fastened or by means of studs welded on to the base carrier plates which again can be fastened externally, thus eliminating any weak points within the surface of the lining system.

As with most wear resistant materials the success of the system often depends on the quality and accuracy of the installation.

Before committing to the use of our K-CLAD, we recommend consultation takes place with one of our qualified engineers in order to assess its suitability for particular applications.

Should you have a requirement for the product to be installed or form part of a system, then we would welcome the opportunity in discussing your requirements for the design, manufacture, installation and erection of the system using our fully trained staff and workforce, alternatively we will be happy to consult with or supervise your own workforce.

- Good impact and sliding abrasion resistance

- Performs at elevated

- temperature

- Fabricated using traditional methods

- Can be repaired in position