Claro Inc

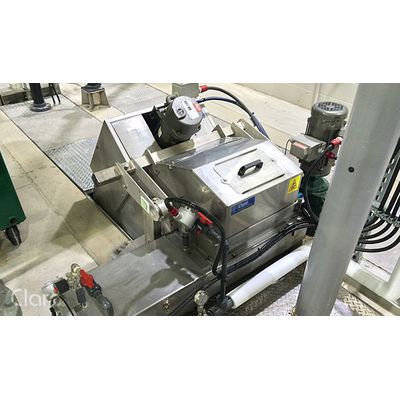

Claro - Wash Press Screw Compactor

FromClaro Inc

Claro is pleased to offer a high-quality wash press screw compactor for the effective washing, dewatering, compaction, transport & automatic hygienic bagging of screenings. Screenings are well-cleaned of organics, dry, diminished in disposal volume, & deposited into an optional hygienic bagger that automatically unfolds into a receiving bin. Robust & versatile construction. Fully-enclosed & odor-controlled. Standard capacity sizes & configurations are available to meet a broad range of application scenarios. Thousands of installations. Screening press compactor also available without washing feature.

Most popular related searches

screw compactor

press compactor

screw press

grit removal system

odor control

screw washing machine

grit remover

compactor unit

screen press

grit removal

- Effective washing with a very compact footprint.

- Integrated heavy-duty thrust bearings & a high-torque drive unit to assure optimal dryness & compaction of screenings material.

- Slow transportation of screenings for gentle, thorough washing without maceration.

- Completely enclosed, odor-controlled hygienic operation.

- Robust screw press compactor unit including double-body construction.

- Tight tolerances between screw & trough delivers superior process performance.

- Only one moving part: a special microalloy steel or stainless steel spiral.

- Easy access for inspection/maintenance of wash & press zone: unit easily dismantles at both front & back end.

- No maintenance-prone wedgewire & no wearable brushes to replace.

- Long compaction tubes up to 6 m. (20 ft.) in length for transport of screenings – can eliminate conveyor.

- Optional automatic hygienic bagger.

- Complete systems for sole-supplier responsibility.