- Home

- Companies

- Nordson BKG GmbH

- Products

- Nordson BKG - Model EDI Ultraflow I - ...

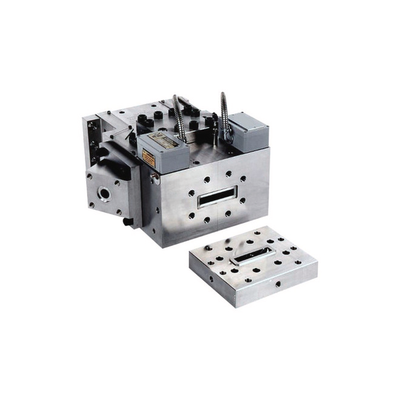

Nordson BKG - Model EDI Ultraflow I -Coextrusion Feedblocks

Our fixed geometry feedblock is a proven design, enhanced by a collaboration of coextrusion expertise between our world-class design engineers and industry partners.

The Ultraflow™ I feedblock premiered in 1992 and has been our most successful feedblock design since. Its robust design and favorable performance in the field has made it the preferred standard for numerous film and sheet producers worldwide.

Why choose a fixed geometry coextrusion feedblock?

Fixed geometry feedblocks are well-suited for dedicated processes or those with a low number of product changeovers. When a change is required, feedblock inserts may be exchanged without having to disassmble the feedblock from the production line.

Designed to Meet Your Needs

- Arrange Layer Sequences: Customizable with an optional selector spool

- Control Flow of Split Streams: Flow inserts are profiled to optimize the layer distributions

- Create Uniform Layers: By changing flow inserts and plugs as well as using flush inserts the layer sequences can be changed. Alternatively, selector spools, optional in the design, enable layer sequence arrangements to be preset upstream of the feedblock’s combining point

- Establish Entrance Locations: Controllable linear valves allow for highly precise layer ratio changes

- Multiply Layers: Compatible with the EDI® Layer Multiplier system

Designed to Suit Your Process

- Ideal Applications: Barrier Film, Barrier Sheet, Extrusion Coating & Laminating, CPP Film, Stretch Film, Sheet

- Layer Ratio Adjustability (without downtime): ± 10%

- Maximum Number of Extruders: 8

- Maximum Number of Layers: 13