- Home

- Companies

- Ultra Check, Inc.

- Products

- Ultra Check - Model Safe Sleeve - ...

Ultra Check - Model Safe Sleeve -Complete Guage Pole Seal Unit

Ultra Check's Safe Sleeve is a complete gauge pole seal unit that seals the outside of gauge poles (guide pole) and the deck / well opening. This system alone provides a 96% reduction in emission losses, but combined with a Float system it provides a 99% loss reduction. The Standard Safe Sleeve is a gauge pole emission control system that includes an aluminum or Stainless Steel Slide Plate with a bonded Buna-N or Viton rubber gasket to cover the deck / well opening, a PTFE Zero Gap Pole Wiper and a tapered PTFE, Aluminum, or Stainless Steel Pole Sleeve / SkirtThe “Slide Plate” sets on top of the well, sealing the well opening with the Buna-N rubber gasket. The slide plate is held in place with the anti-rotation device, and can shift with the roof movement. Built onto the slide plate is the pole wiper cavity with its cover.

The “Zero Gap Pole Wiper” is housed inside the pole wiper cavity. The pole wiper is allowed to move inside the cavity maintaining a Zero Gap with the pole. The wiper offers little or no friction to the pole; it will not bunch up causing it to lose its seal or lift the slide plate off of the well.

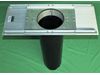

Attached to the bottom of the Slide Plate is a PTFE “Pole Sleeve/Skirt” (as shown in picture 1). Unlike metal, the fabric is flexible so it does not bind, will not damage the roof or cause the slide plate to lift. The sleeve/skirt is tapered so that with only minimal force it touches the pole. The tapered shape is maintained by a unique stainless steel spring arrangement that permits flexibility while the sleeve maintains contact with the pole. While PTFE is our Standard we also will fabricate using an Aluminum or SS Skirt.

These standard style Safe Sleeves are manufactured in standard pipe sizes; 2”, 4”, 6”, 8”, 10” and 12”, and are priced according to size. These standard Safe Sleeves can also be custom made and modified as required to suit the tank design. For example, if a tank needed a larger sized slide plate to cover a larger than normal well opening (see below). For the tanks that handle more caustic and volatile liquids, Ultra Check can modify the present designs to meet the customers’ needs.

Installation of the Safe Sleeve is fairly simple and can be done on an operating tank, by two men in less than an hour. The Safe Sleeve is readily visible and can be easily inspected.