Berahn - Complete Recycling System

The Complete Recycling System-BERAHN® [CRS-BERAHN®] is the basic technology and therefore linchpin of all applications and core technology in every plant. The system consists of the hardware – the module – and the process. Only the perfect interaction of the two components allow the production of the goods in the demanded quality.

Both, the process as well as the technique can be aligned for different applications. One the one hand, this enables the operation in different industries with variable input materials. On the other hand, the respective resulting products can be adapted to the markets needs and hence, sold profitable. One example is the aqua-CRS-BERAHN® technology.

The CRS-BERAHN® combines technical, economical, and environmental aspects.

Technical

- The technology corresponds to European and German environment and safety standards

- The process works pressureless under exclusion of oxygen within a middle temperature range

- Process runs fully automatic

Economical

- No additives or catalysts necessary

- Normally no pre-treatment of the input material is required

- Low running and maintenance costs of the modules, customary maintenance costs in the industry for attendant equipment

- Often an own, autarky power supply is possible

Ecological

- Normally no waste is generated

- Power production out of own products and therefore high saving of fossil resources

- Multiple recycling of the waste/the product and hence a significant saving of raw material and other resources

- No catalysts or other additives

- Procedure works without pressure under exclusion of oxygen

- Middle temperature range

- Scrap car tires are recycled in a whole

- First-class and steady quality of BERAHN end products

- Production of power and heat/cold to run the plant self sustaining and power and heat/cold to sale by utilizing BERAHN-Oil and BERAHN-Gas

- Low running and maintenance costs of the modules

- Respectable return on investment for the plant operator

- Emission-free production

- No residual waste

- Autarky power and heat supply by utilizing self generated products

- Real resource cycle

The Complete Recycling System-BERAHN industrial plant is build modularly and allows an extension after market demand. Depending on the supply of input material and demand of BERAHN end products the facility can be extended with additional modules. Only limiting factor is the size of the production hall.

Since every single module operates independently and stand-alone, no module needs to be turned off while extending the factory or accomplishing maintenance. Therefore a continuous running of the plant is granted.

The Module

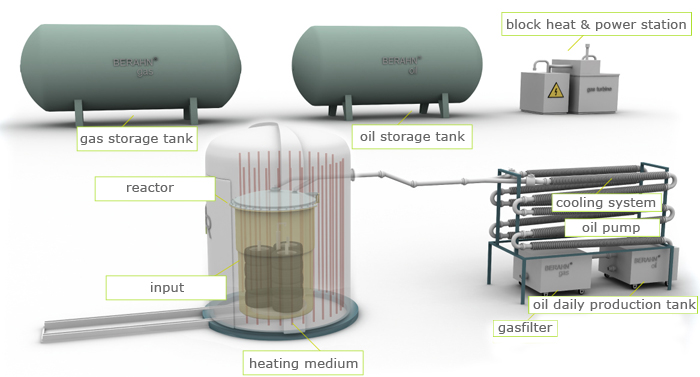

One Complete Recycling System-BERAHN module already allows an entire process. It consists of one heating medium, three reactors, one cooling system, one gas-filter, one oil pump, and one collecting tank for daily produced oil.

In order to achieve highest efficiency every reactor has to be filled with at least 0.75 metric tons of input (with or without rim / metal). Running one complete process with all three reactors means the recycling of at least 2.25 metric tons of input per module within one day.

The following illustration shows a single module with an additional block heat and power station, a gas-storage, and an oil-storage.

The patented Complete Recycling System-BERAHN procedure is characterized by its amazing simplicity. There are no additives or catalysts. The pyrolysis process takes place within a middle temperature range under exclusion of oxygen and works without any pressure.

The plant operates 24 hours / 7 days. That is why one module consists of three reactors. One reactor is located in the preparation area, one is within the process, and one is in the emptying area.

Following the efficient work flow within the recycling plant using the example of scrap car tires as input material is described.

Work flow within a recycling plant using the example of scrap car tires

One reactor is loaded with at least 0.75 metric tons of scrap car tires, whereas those are taken in a whole - not cut into pieces – and without rim. From experience, one reactor is loaded with 0.8 metric tons in average. When there is a free heating medium, the reactor is transported to the heating medium with the help of machines and put into it. After closing the heating medium, connecting the cooling, and activation of the START button on the control system the pyrolysis process starts.

During the procedure gas is produces which condenses to oil within the cooling coil. The produced BERAHN-Oil is collected in the daily oil tank and pumped to an oil collection tank after every process. The remaining BERAHN-Gas is led through a gas filter and then directly to the block heat and power station to utilize it.

The entire process runs automatically and lasts 8 hours. The control system shows the end of one process.

After the pyrolysis process the reactor is transported to the cooling down area. In the reactor there are still BERAHN-Carbon and spring steel.

When the reactor has reached an uncritical temperature for the staff, it is transported to the separation area and emptied via a special dumping station. Then the BERAHN-Carbon will be divided from the spring steel, both is collected separately and packed as customer demand.

Finally the emptied reactor is reloaded and a new work flow starts.

The size and therefore the capacity and profitability of a Complete Recycling System-BERAHN®plant are decisive depending on the kind of input material and the available amount within a year. Not every input material and not every amount of it is profitable. Basically true is: the higher the capacity and therefore the greater the plant the higher is the return on investment.

When recycling scrap car tires, for instance, there must be available at least 6,000 metric tons within a year to run the plant profitable. This corresponds to an 8-module-plant.

- Realization using the example of an 8-module and 17-module-plant for scrap car tires

An 8-module plant consists of (8 x 3 =) 24 reactors. Each reactor goes through the pyrolysis process once a day, loaded with at least 750 kg scrap car tires. Hence, every day at least (24 x 0.75 =) 18 metric tons of tires are recycled within 24 hours. When 17 modules are running, at least 38.25 metric tons of scrap car tires are recycled.